Inspection of Crankshaft during Overhaul of V8 Engines 35, 39, and 42

ENGINE

OVERHAUL

49

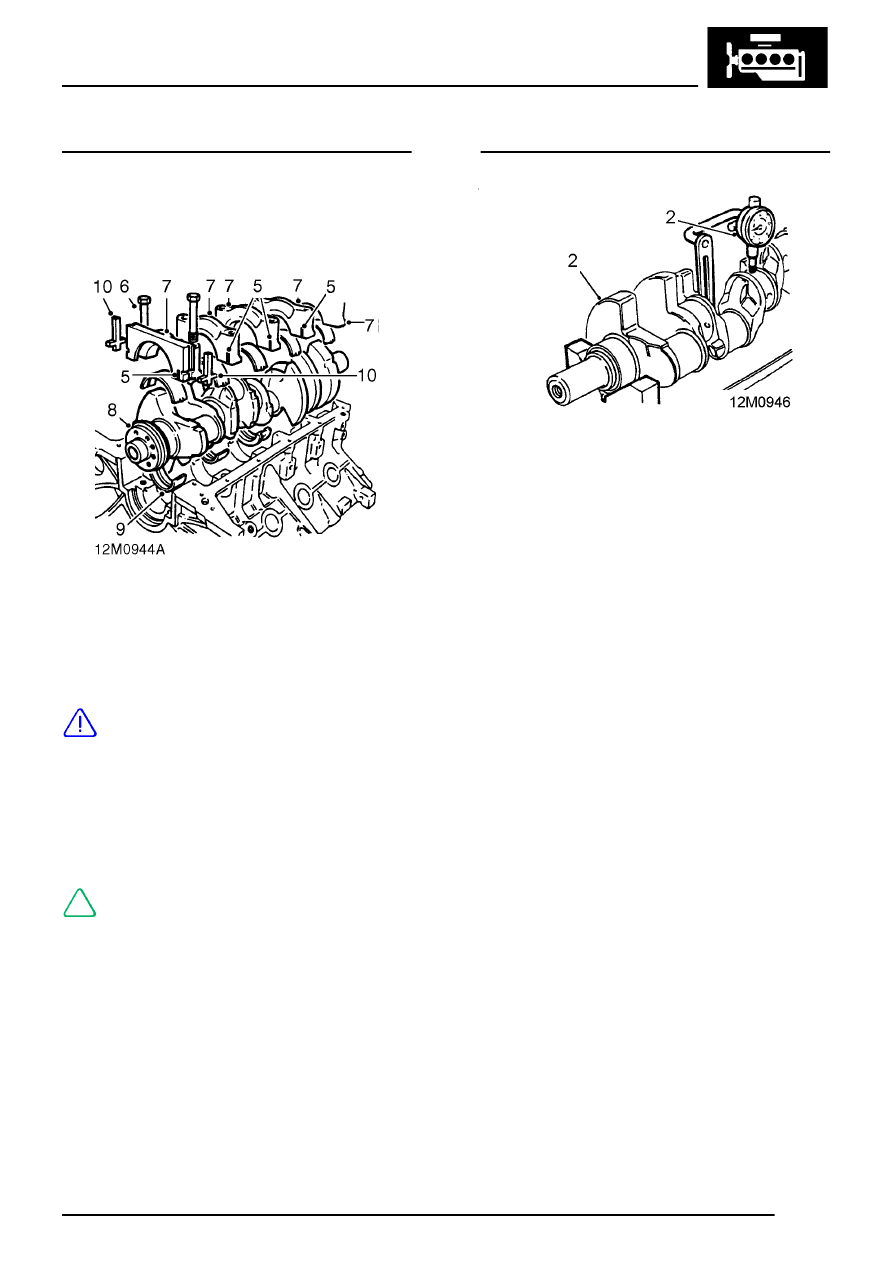

Crankshaft - remove

1. Remove flywheel or drive plate and ring gear

assembly.

2. Remove timing cover.

3. Remove timing gears.

4. Remove big-end bearings.

5. Make suitable reference marks between each

main bearing cap and cylinder block.

6. Starting at centre main bearing and working

outwards, progressively slacken then remove

10 main bearing cap bolts.

CAUTION: Keep bolts in their fitted order.

7. Remove 5 main bearing caps and bearing

shells, discard shells.

8. Lift out crankshaft and rear oil seal. Remove

and discard oil seal.

9. Remove and discard 5 bearing shells from

cylinder block.

NOTE: Main bearing shells must be

replaced whenever they are removed.

10. Remove and discard cruciform seals from rear

main bearing cap.

11. Remove Woodruff key from crankshaft.

Crankshaft - inspection

1. Clean crankshaft and blow out oil passages.

2. Support crankshaft front and rear bearing

journals on vee blocks, and using a DTI,

measure run-out on centre main bearing.

Maximum permitted run-out = 0.08 mm (0.003

in)

If run-out exceeds permitted maximum,

crankshaft is unsuitable for regrinding and

should be replaced.