V8 Engine 3.5 3.9 4.2

ENGINE

48

OVERHAUL

Big-end bearings - refit

1. Fit new bearing shells to each connecting rod.

NOTE: Big-end bearings are available in

0.254 and 0.508 mm (0.01 and 0.02 in)

oversizes.

2. Lubricate bearing shells and crankshaft

journals with engine oil.

3. Pull connecting rods on to crankshaft journals

and remove plastic tubing from bolts - if fitted.

4. Fit new bearing shells to each big-end bearing

cap.

NOTE: If crankshaft has been reground,

ensure appropriate oversize bearing shells

are fitted.

5. Lubricate bearing shells and fit bearing caps

ensuring reference marks on connecting rods

and bearing caps are aligned.

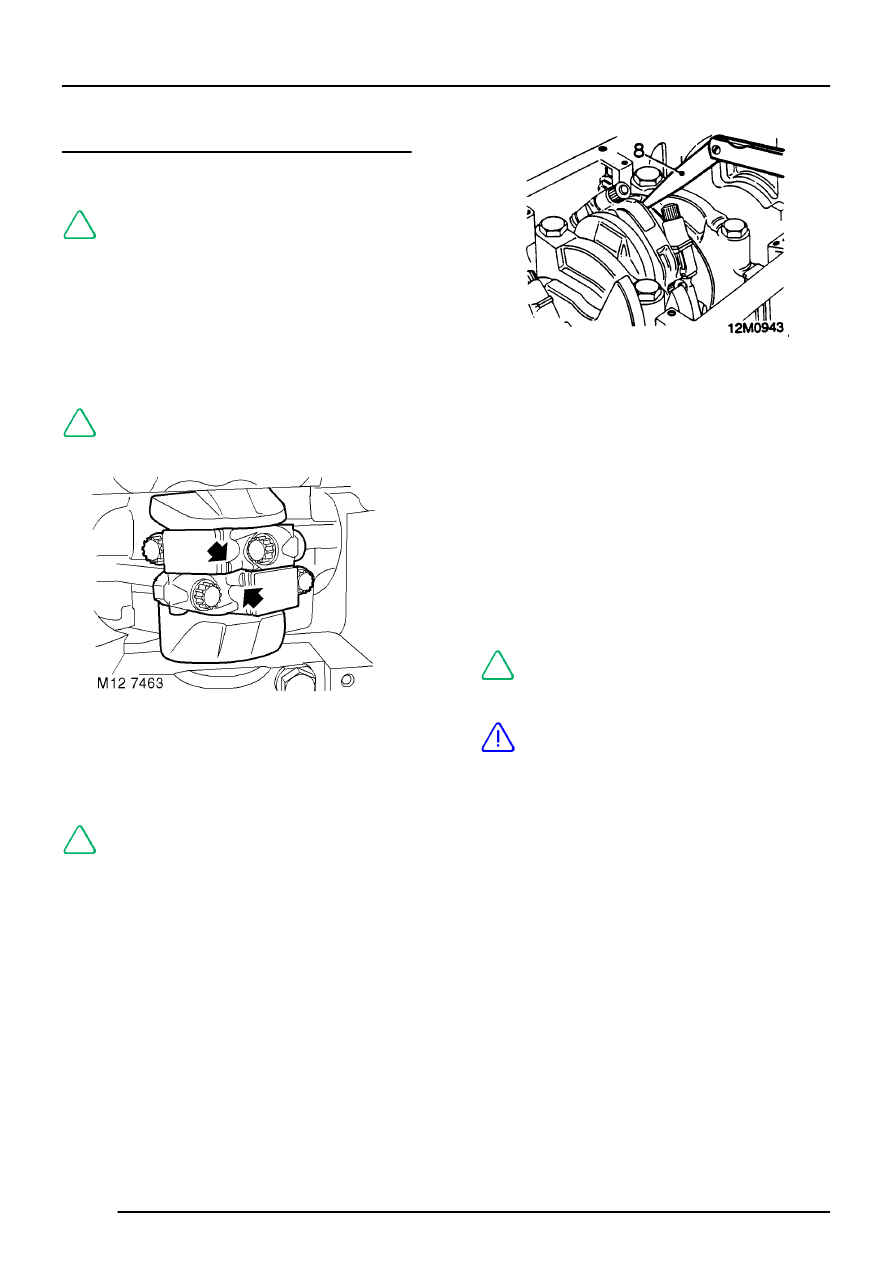

NOTE: Rib on edge of bearing cap must

face towards front of engine on RH bank

of cylinders and towards rear on LH bank

of cylinders.

6. Fit bearing cap nuts/bolts and tighten to:

Nuts - 50 Nm (37 lbf.ft).

Bolts:

Stage 1 - 20 Nm (15 lbf.ft)

Stage 2 - Further 80

°

7. Check connecting rods move freely sideways

on crankshaft. Tightness indicates insufficient

bearing clearance or misaligned connecting

rod.

8. Check clearance between connecting rods on

each crankshaft journal.

Connecting rod clearance = 0.15 to 0.36 mm

(0.006 to 0.014 in).

9. Clean oil strainer.

Engines numbers without suffix B

10. Clean mating faces of strainer and cylinder

block.

11. Fit new gasket, dry.

12. Position oil strainer to stud.

13. Fit oil strainer, fit nut but do not tighten at this

stage.

NOTE: This will allow for correct

positioning of oil strainer when timing

cover is fitted.

CAUTION: Ensure nut is tightened to 22

Nm (16 lbf.ft) when oil pick-up pipe is fitted

to timing cover.

Engines numbers with suffix B

14. Clean mating faces on strainer and cylinder

block.

15. Fit new gasket to strainer, position strainer, fit

bolts and tighten to 10 Nm (7 lbf.ft).

16. Fit timing chain and gears.