Sable V6-183 3.0L DOHC VIN S MFI (1997)

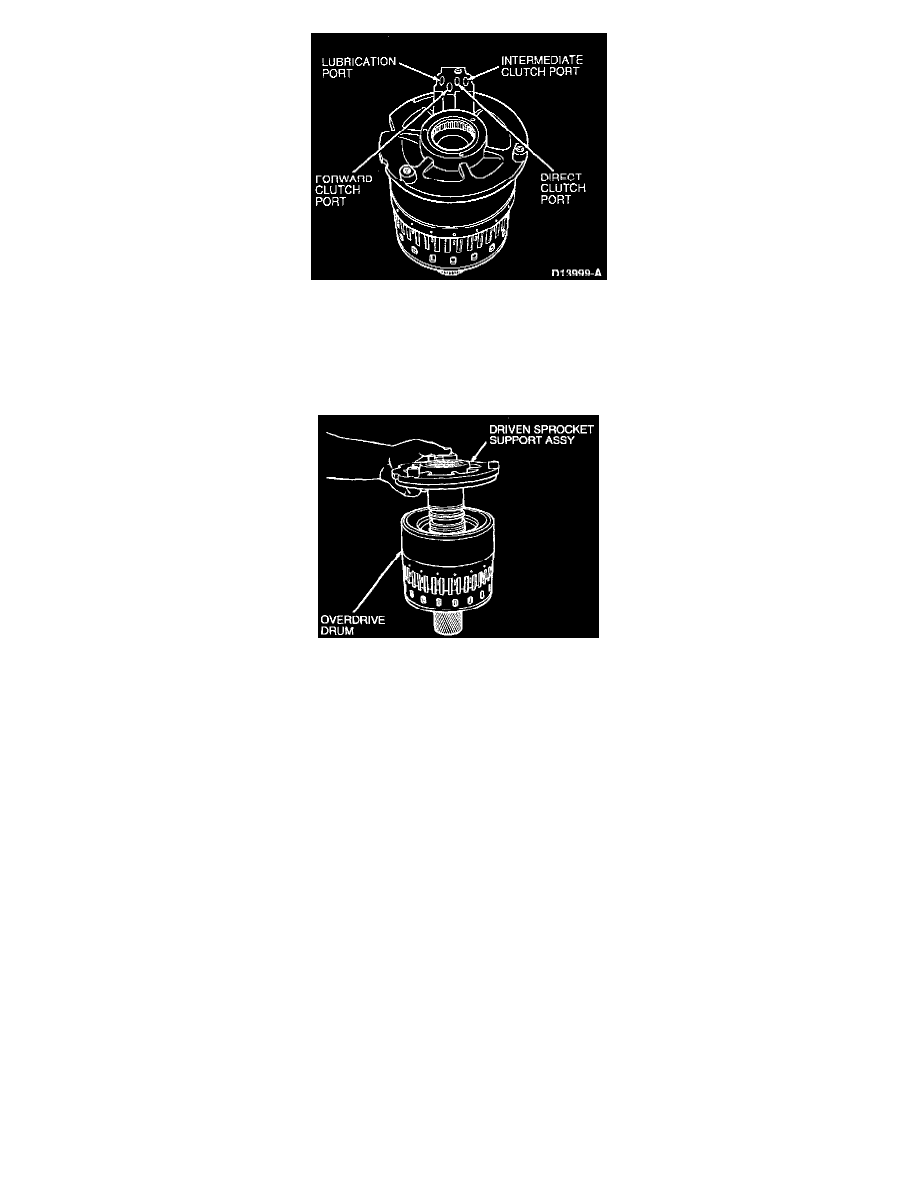

11. Apply pressurized air to the driven sprocket support ports as shown to check for seals damaged during assembly. If air can be heard leaking past

seals, the seals must be replaced.

WARNING: To prevent injury, wear eye protection when using pressurized air.

NOTE: Be sure shop air is dry and regulated at 276 kPa (40 psi).

12. Remove driven sprocket support from overdrive drum.