Endeavor V6-3.8L SOHC (2004)

Alignment: Service and Repair

Front

FRONT WHEEL ALIGNMENT CHECK AND ADJUSTMENT

CAUTION: On vehicles with ASC, if the wheel alignment is adjusted, always carry out steering wheel sensor calibration. This is necessary because

the TCL/ASC-ECU should update the steering neutral point. Measure wheel alignment with alignment equipment on a level surface. The front

suspension, steering system, wheels, and tires should be serviced to normal condition before measuring wheel alignment.

TOE-IN

Standard value: 0 ± 3 mm (0 ± 0.12 inch)

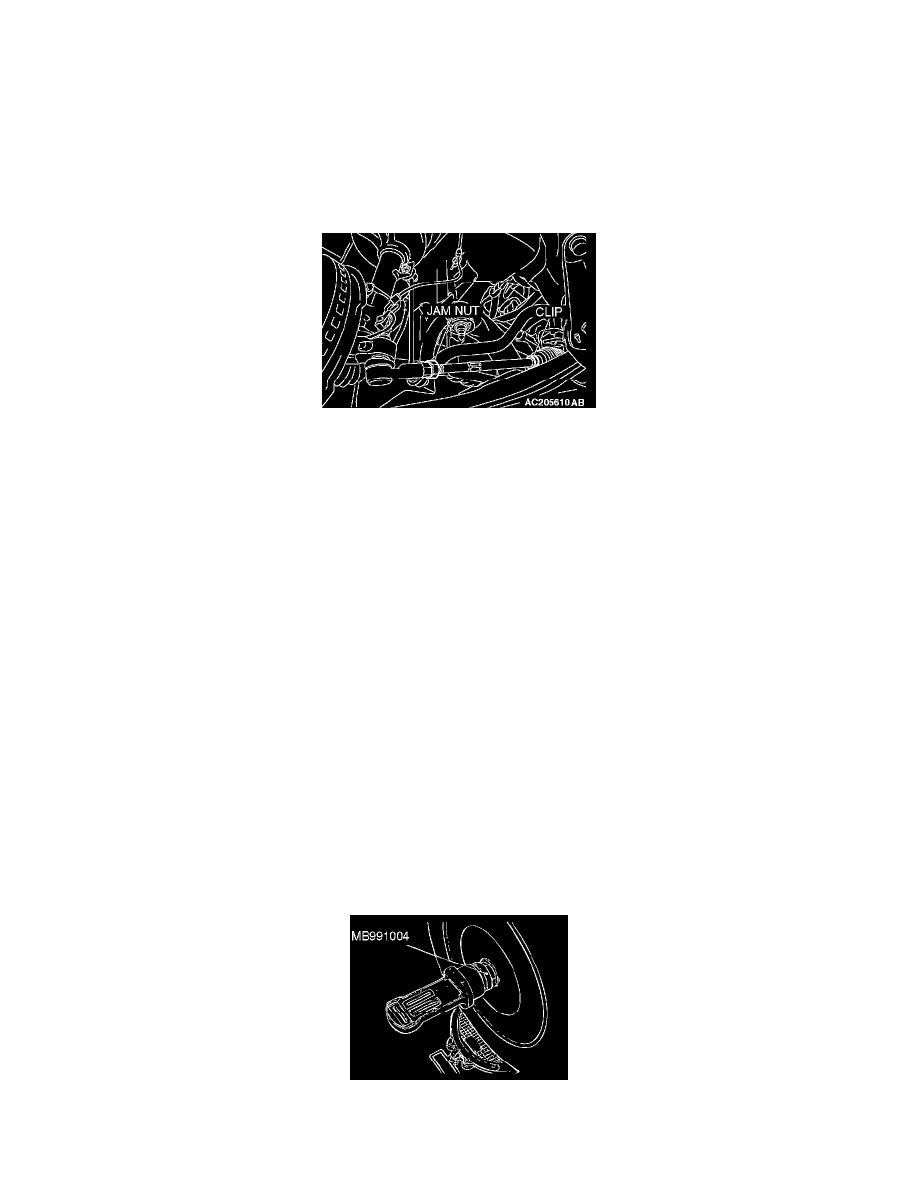

1. Adjust the toe-in by undoing the clip and jam nut, and turning the left and right tie rod turnbuckles by the same amount (in opposite directions).

NOTE: The toe will move out as the left turnbuckle is turned toward the front of the vehicle and the right turnbuckle is turned toward the rear of

the vehicle.

2. Install the clip and tighten the jam nut to the specified torque.

Tightening torque: 52 ± 2 Nm (38 ± 2 ft. lbs.)

3. Confirm that the toe-in is at the standard value.

4. Use a turning radius gauge to check that the steering angle is at the standard value.

STEERING ANGLE

Standard value:

35°36' ± 2°00' <Inner wheel>

30°00' <Outer wheel (reference)>

5. On vehicles with ASC, if the toe-in is adjusted, always carry out steering wheel sensor calibration.

CAMBER, CASTER AND KINGPIN INCLINATION

Required Special Tool:

^

MB991004: Wheel Alignment Gauge Attachment

Standard value:

Camber: 0°00' ± 30' (Left/right deviation within 30')

Caster: 3°00' ± 30' (Left/right deviation within 30')

Kingpin inclination: 12°50' ± 1°30'

NOTE: Caster are preset at the factory and cannot be adjusted.

CAUTION: Never subject the wheel bearings to the vehicle load when the drive shaft nuts are loosened.

NOTE: Attach the camber/caster/kingpin gauge to the drive shaft by using special tool MB991004. Tighten special tool MB991004 to the same

torque 236 ± 19 Nm (174 ± 14 ft. lbs.) as the driveshaft nut.