Leon Mk1

|

|

|

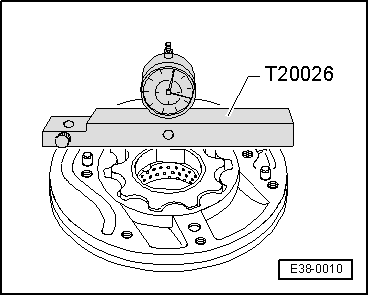

| 1 - | Piston ring |

| q | Checking the correct adjustment |

| q | Do not over-expand |

| 2 - | Bolt |

| q | 10 Nm |

| 3 - | Steered wheel support |

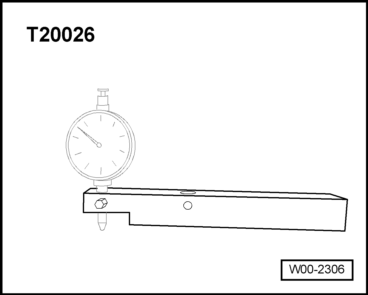

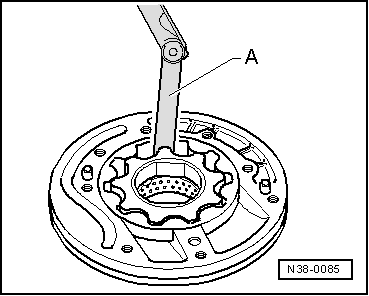

| 4 - | Outer sprocket |

| q | Check for wear → Fig. and → Fig. |

| 5 - | Inner sprocket |

| q | Check for wear → Fig. and → Fig. |

| 6 - | ATF pump housing |

| 7 - | O-ring |

| q | Always renew |

| 8 - | Torque converter seal |

| q | Dismantling and fitting → Chapter |

| Measured dimension | Wear limit (mm) |

| Height difference between the ATF pump housing and the outer sprocket | 0.04 |

| Height difference between the ATF pump housing and the inner sprocket | 0.04 |

|

|