Leon Mk1

|

|

|

|

|

Note!

Note!| t | Replace the disks and clutch presses that have damaged or loose riveted joints. |

| t | Make the disk match the corresponding clutch press, as per the Microfiche for Spares and the identification letters for the engine. |

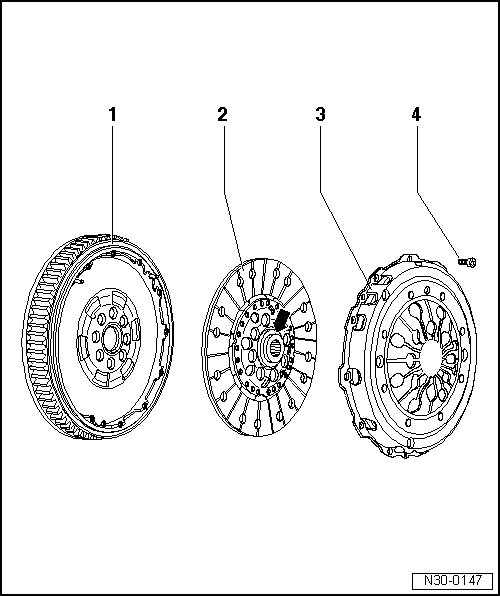

| 1 - | The engine wheel |

| q | Make sure that the centring linchpins are well placed. |

| q | The contact surface with the clutch disk should not have any grooves and they must be free from oil and grease. |

| q | Dismounting and assembling → Rep. Gr.13 |

| 2 - | Disk of clutch |

| q | Diameter → Chapter |

| q | Position for assembly if the wheel has two parts: the shortest boss -arrow- remains facing towards the clutch press. |

| q | Position for assembly if the wheel is a single: the spring housing remains facing towards the press. |

| q | Grease the notches slightly. |

Note!

Note!| t | Clean the notches in the main shaft, and in the clutch disk used, remove the corrosion and apply a very fine layer of grease Spare No. -G 000 100-, on the notches in the main shaft. |

| t | Then the clutch disk must be moved back and forth over the main shaft until the hub slides smoothly across the shaft. Remove the remains of excess grease. |

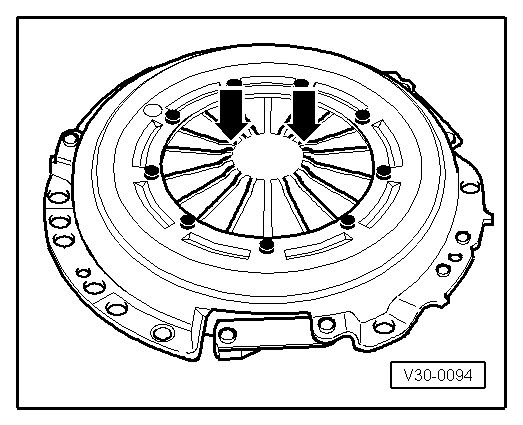

| 3 - | Clutch press |

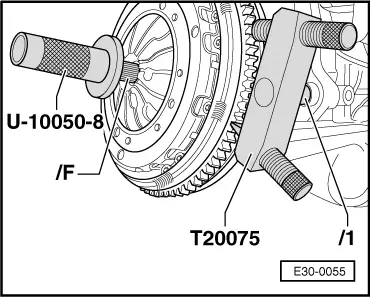

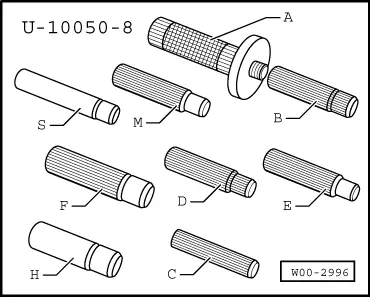

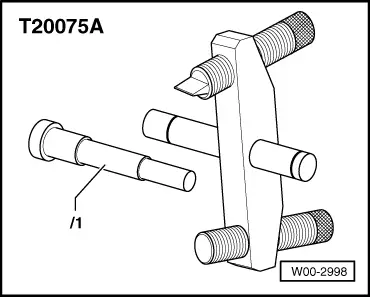

| q | Dismounting and assembling → Fig. |

| q | Check the ends of the diaphragm → Fig. |

Note!

Note!| The clutch press is now greased and protected against corrosion. Only the contact surface can be cleaned, otherwise the useful life of the clutch is reduced. |

| 4 - | Bolt |

| q | Consult the microfiche for Spares in order to assign it |

| q | If the wheel has two parts 13 Nm |

| q | If the wheel is a single one 20 Nm |

| q | Loosen and tighten in a cross in several stages |

|

|