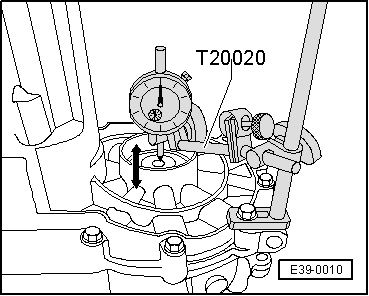

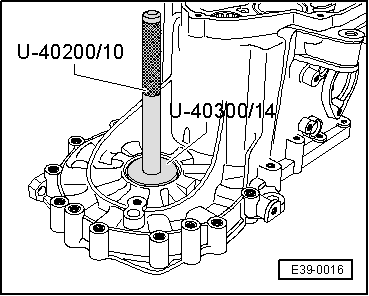

| The diversity of the adjustment washers that exist allows the necessary thickness to be determined precisely for making a proper adjustment of the differential. |

| –

| Should the thickness of the adjustment washer needed be thicker than the thickness that appear in the Table, two adjustment washers may be fitted, the thickness for which when added together, correspond to the reading found. |

| –

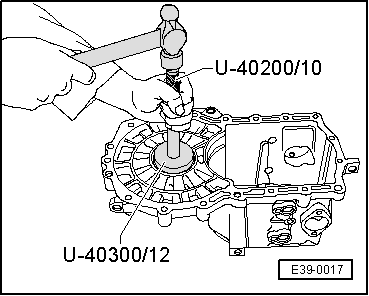

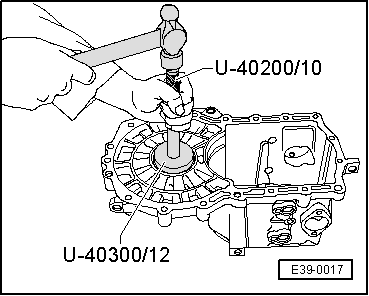

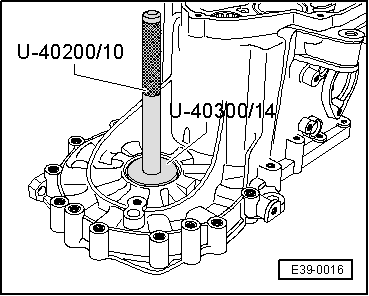

| Once the adjustment washer needed has been determined, remove the tester. |

| –

| Extract the bolts that attach both casings and separate the gearbox casing. |

| –

| Separate the differential. |

|

|

|

Note!

Note!

Note!

Note!