Leon Mk1

| Input shaft: dismantling and assembling |

| Special tools and workshop equipment required |

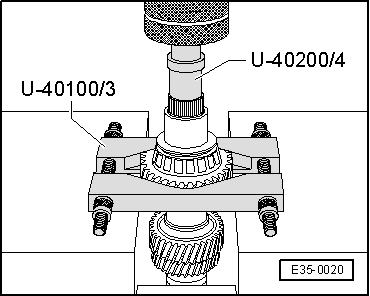

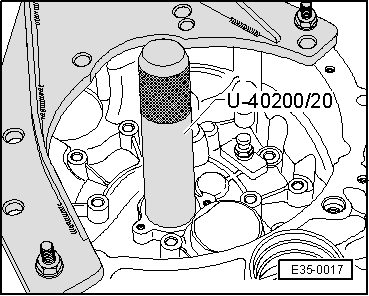

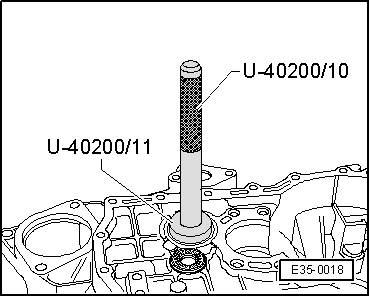

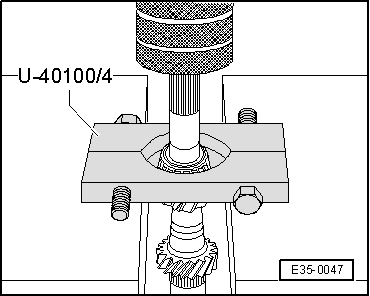

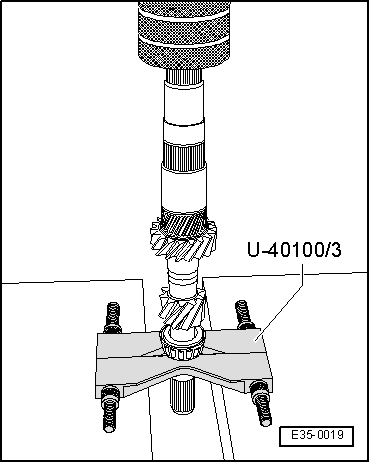

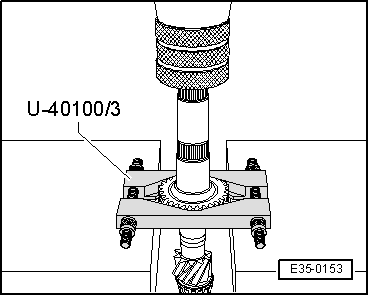

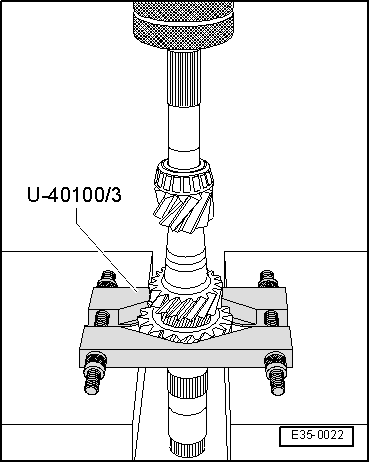

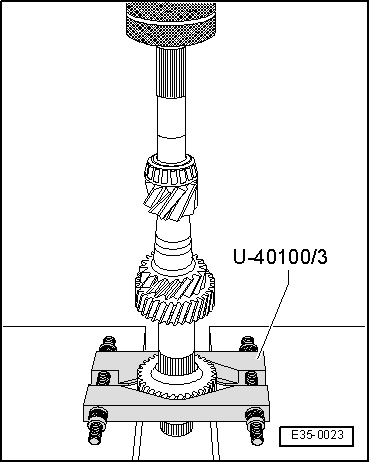

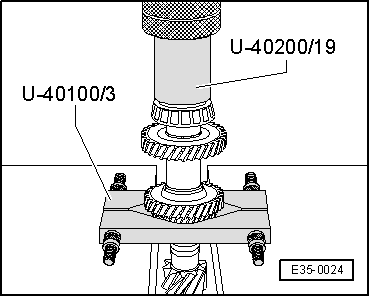

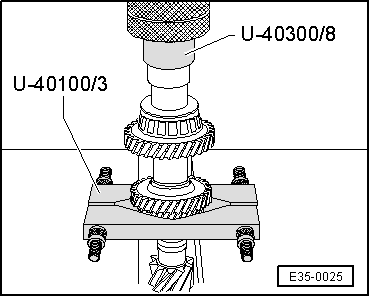

| t | Gearbox extractor set -U-40100- |

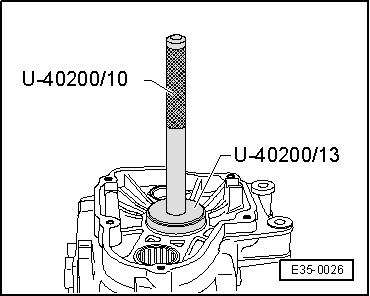

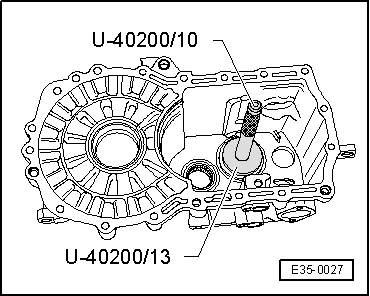

| t | Gearbox repair set -U-40200- |

| t | Gearbox repair set -U-40300- |

| t | Circlip opening pliers -A-81124- |

Note!

Note!| t | Whenever new gears are fitted consult the technical data → Chapter, Code letters, group numbers, ratios, filling quantities. |

| t | The input shaft must be adjusted whenever elements have been replaced which could affect the position of the roller bearings. Refer to Adjustment chart → Chapter. |

| 1 - | Clutch housing |

| q | Repairing → Chapter |

| 2 - | Outer track, roller bearing |

| q | Remove → Fig. |

| q | Fit → Fig. |

| 3 - | Roller bearing |

| q | Remove → Fig. |

| q | Fit → Fig. |

| 4 - | Input shaft |

| q | Adjusting → Chapter |

| 5 - | 3rd gear |

| q | Remove → Fig. |

| q | Fit → Fig. |

| q | Assembly position: the collar must be facing the 4th gear |

| 6 - | Safety ring |

| q | Use tool -A-81124- to remove the circlip |

| q | Always renew |

| 7 - | 4th gear |

| q | Remove together with the roller bearings → Item, stop washer → Item and bush → Item → Fig. |

| q | Fit → Fig. |

| q | Assembly position: the collar must be facing the 3rd gear |

| 8 - | Roller bearing |

| q | Remove → Fig. |

| q | Fit → Fig. |

| 9 - | Stop washer |

| q | Remove → Fig. |

| q | Fit → Fig. |

| 10 - | Outer track, roller bearing |

| q | Remove → Fig. |

| q | Fit → Fig. |

| 11 - | Shim |

| q | For the input shaft |

| q | Determine thickness → Anchor |

| 12 - | Gearbox casing |

| q | Repairing → Chapter |

| 13 - | Needle bearing bush |

| q | Remove → Fig. |

| q | Before assembling, fit the stop washer → Item |

| q | Fit → Fig. |

| 14 - | Needle roller bearing |

| 15 - | Sliding 5th gear |

| q | Remove with the 5th gear syncromesh assembly → Chapter |

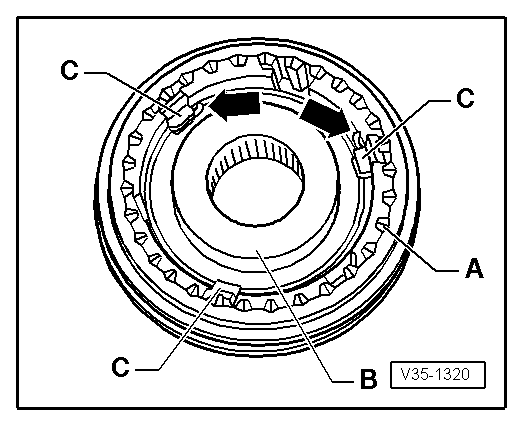

| 16 - | Syncromesh ring 5th gear |

| q | Check wear → Anchor |

| 17 - | Spring |

| q | Fit → Fig. |

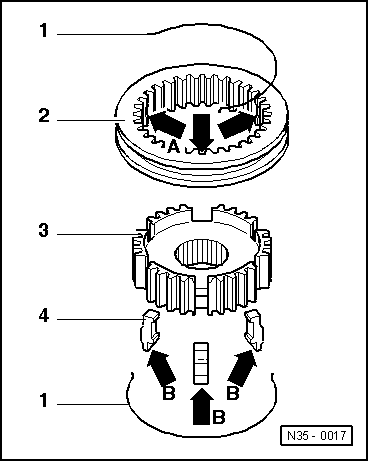

| 18 - | Locking keyways |

| q | Fit → Fig. |

| 19 - | Syncromesh hub |

| q | Fit → Fig. |

| 20 - | Sliding sleeve 5th gear |

| q | Fit → Fig. |

| 21 - | Plate spring |

| q | Assembly position: The concave side should be facing the 5th gear → Chapter |

| 22 - | Securing screw for 5th gear |

| q | 80 Nm |

| q | The screw head incorporates a housing for the plate spring → Item |

| q | Fit → Chapter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note!

Note!

|

|

|

|

|

|