Leon Mk1

| Main shaft: dismounting and assembling |

| t | If it is necessary, assemble new pinions, consult section for Identification initials, assignation of groups, reductions, amounts for filling Group → Chapter. |

| t | The main shaft must be adjusted whenever parts have been replaced that may affect the position of the tapered roller bearings. Consult the Adjustment Chart → Chapter. |

| Assembly Chart |

| 1 - | Clutch casing |

| 2 - | Outer track, tapered roller bearings |

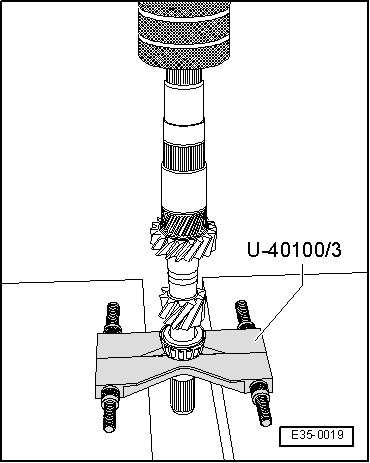

| q | Dismounting → Fig. |

| q | Assembling → Fig. |

| 3 - | Tapered roller bearing |

| q | Dismounting → Fig. |

| q | Assembling → Fig. |

| 4 - | Main shaft |

| q | Adjusting the main shaft → Chapter |

| 5 - | 3rd gear pinion |

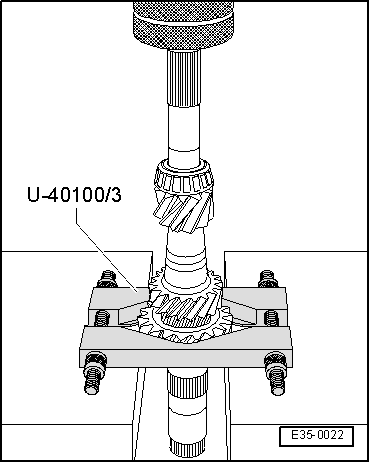

| q | Dismounting → Fig. |

| q | Assembling → Fig. |

| q | Position for assembly: the collar must remain facing towards the 4th gear pinion. |

| 6 - | Safety ring |

| q | Use tool -A-81124- for extracting the safety ring. |

| q | Always replace |

| 7 - | 4th gear pinion |

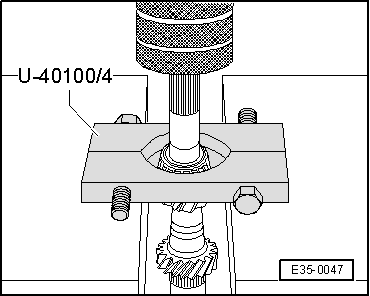

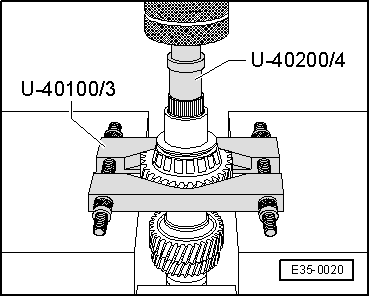

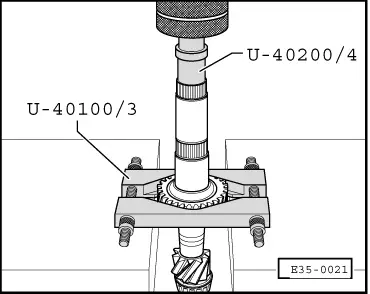

| q | Dismount it together with the tapered roller bearing → Item, the stop washer → Item and the sleeve for the needle bearing → Item, → Fig. |

| q | Assembling → Fig. |

| q | Position for assembly: the collar must remain facing towards the 3rd gear pinion. |

| 8 - | Tapered roller bearing |

| q | Dismount it together with the 4th gear pinion → Item, the stop washer → Item and the sleeve for the needle bearing → Item, → Fig. |

| q | Assembling → Fig. |

| 9 - | Stop washer |

| 10 - | Outer track, tapered roller bearing |

| q | Dismounting → Fig. |

| q | Assembling → Fig. |

| 11 - | Adjustment washer |

| q | For the main shaft |

| q | Finding the thickness → Chapter |

| 12 - | Gearbox casing |

| 13 - | Sleeve for needle bearing |

| q | Dismount together with the 4th gear pinion → Item, the tapered roller bearing → Item and the stop washer → Item, → Fig. |

| q | Before assembling it, put the stop washer into place → Item |

| q | Assembling → Fig. |

| 14 - | Needle bearing |

| 15 - | 5th gear pinion |

| q | Dismount it together with the 5th gear synchroniser unit → Chapter |

| 16 - | 5th gear synchroniser ring |

| q | Check the wear → Chapter |

| 17 - | Spring |

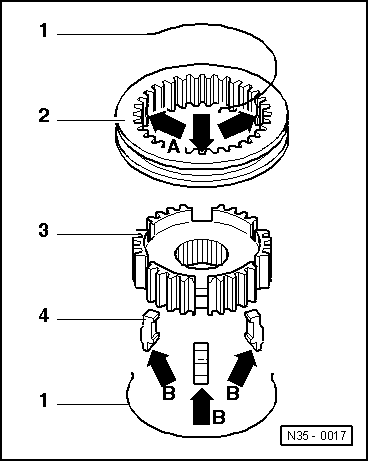

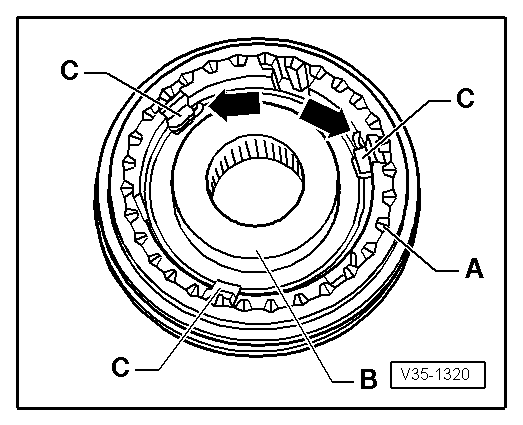

| q | Position for assembly → Fig. |

| 18 - | Blocking pins |

| q | Assembling → Fig. |

| 19 - | Synchronised boss |

| q | Assembling → Fig. |

| 20 - | Movable sleeve for 5th gear |

| q | Assembling → Fig. |

| 21 - | Plate spring |

| q | Position for assembly: the concave side must remain facing towards the 5th gear pinion → Chapter |

| 22 - | Bolt for attaching the 5th gear pinion. 80 Nm |

| q | The head of the bolt has a slot for housing the plate spring → Item |

| q | Assembly → Chapter |

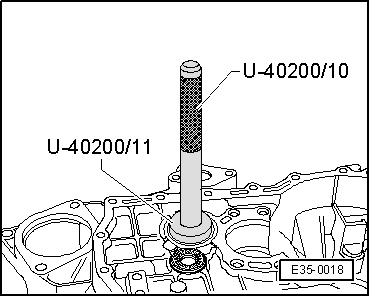

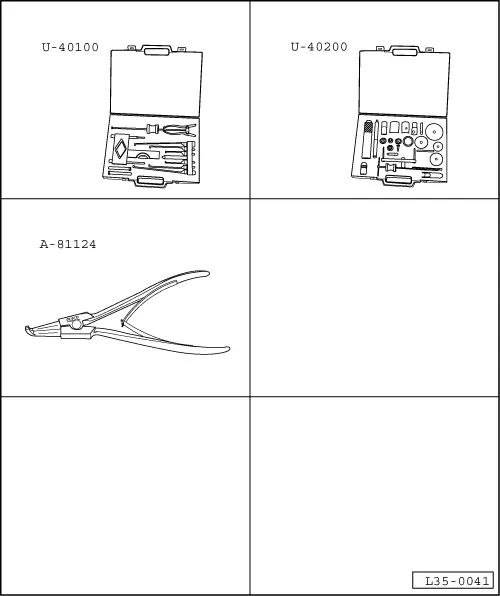

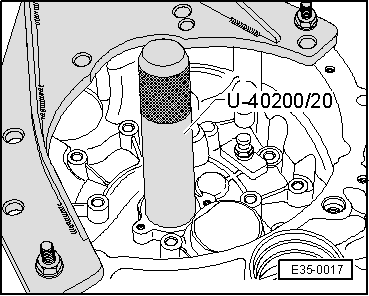

| Special tools and workshop equipment required |

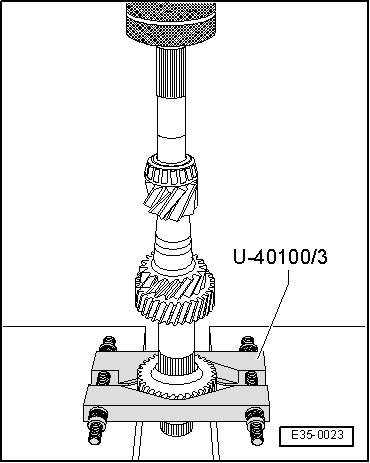

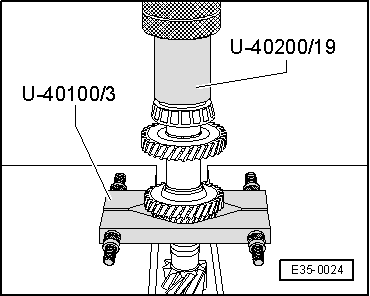

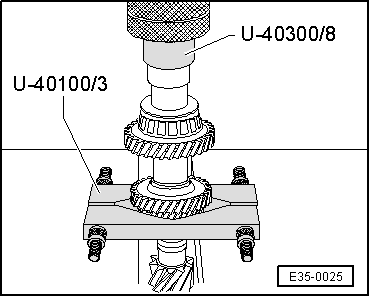

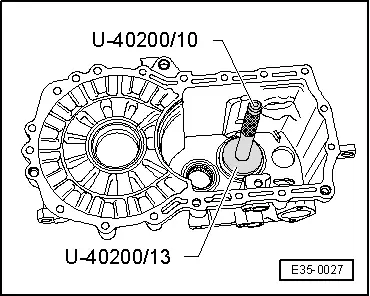

| t | Case for extractors for gearboxes -U-40100- |

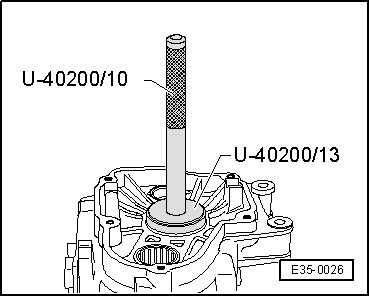

| t | Gearbox repair case -U-40200- |

| t | Pliers for opening elastic rings -A-81124- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note!

Note!

|

|

|

|

|

|