| –

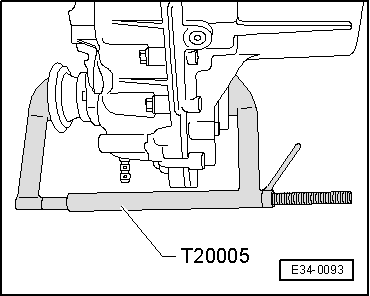

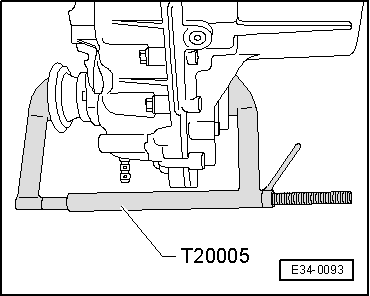

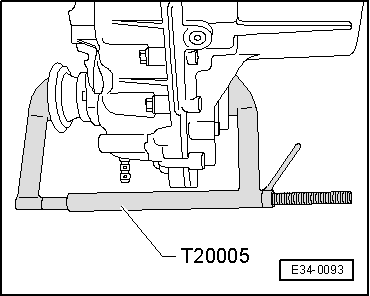

| Fit securing bolt to articulation flange. Use tool -T20005- and tighten the bolt to 25 Nm. |

| –

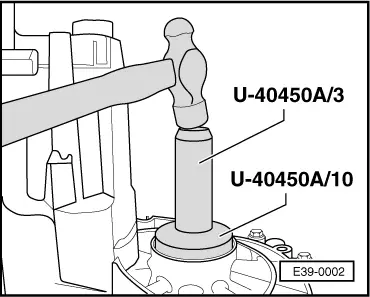

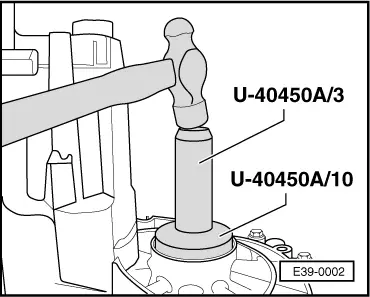

| Fit drive shafts to gearbox flange and tighten bolts to 45 Nm with the correct spanner from tool -U-40020-. |

| –

| Fit the protective cover for the driveshaft to engine to a torque of 35 Nm. |

| –

| Fit counterweight to the sub-frame. |

| t

| Assembly position: According to the mark made during disassembly. If no mark was made, the counterweight should be fitted to the sub-frame in such a way that the greatest distance between the edge of the counterweight and the securing bolts faces the front. |

| –

| Connect the earth battery strap. |

|

|

|

Note!

Note!

Note!

Note!