| –

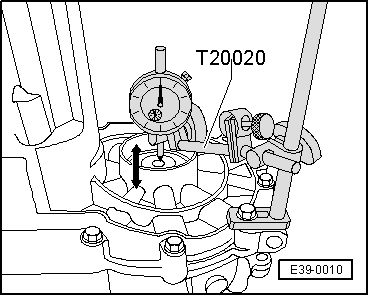

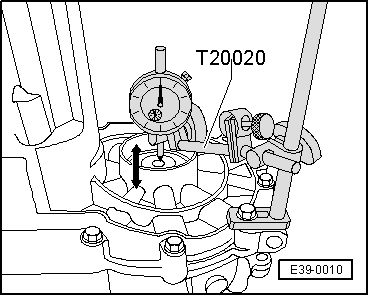

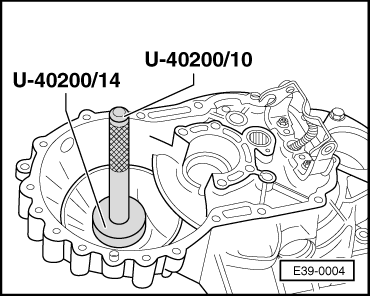

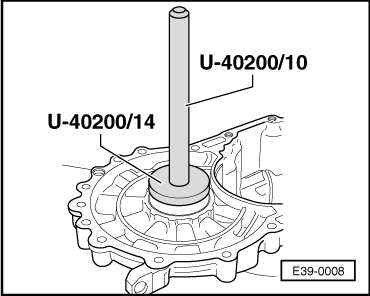

| Fit tool -T20020- on the gearbox casing with a dial gauge. Locate the end of the gauge on the differential, interplacing tool -U-40200A/11-. |

| –

| Adjust the dial gauge to “0” with a pre-tension of 1 mm. |

| –

| Move the differential alternately in the direction of the arrows. |

| –

| Take note of the measurement obtained (e.g. 0.9 mm) |

Note! | When measuring do not turn the differential, because the roller bearings may settle and the reading would be erroneous. |

| The pre-tension of the bearing is obtained by adding a constant pressure value (0.4 mm) to the obtained measurement value of S1 (in the example: 0.90 mm). |

|

|

|

Note!

Note!

Note!

Note!

Note!

Note!