| –

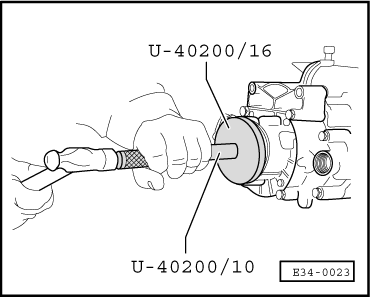

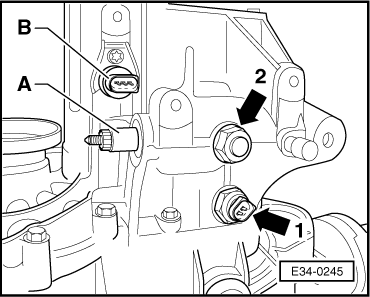

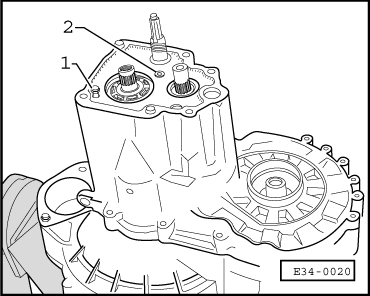

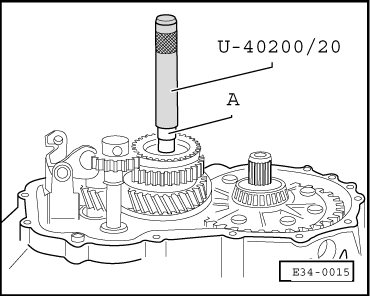

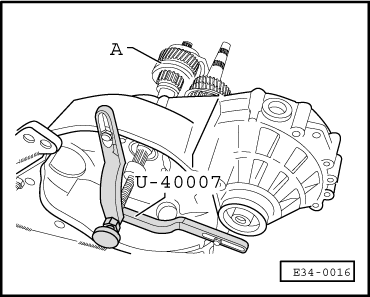

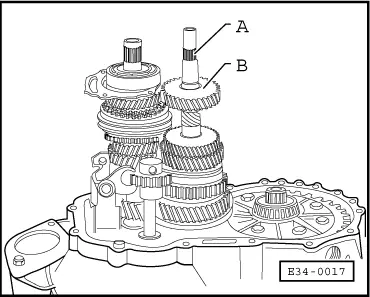

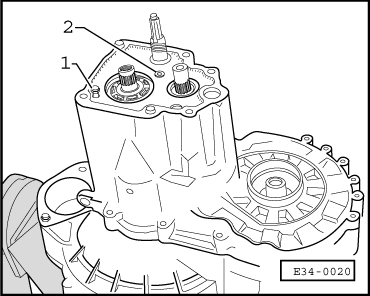

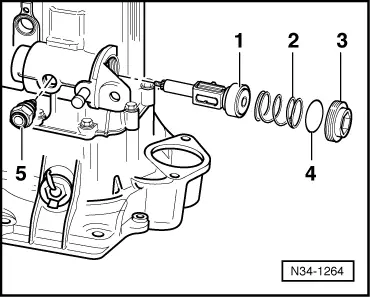

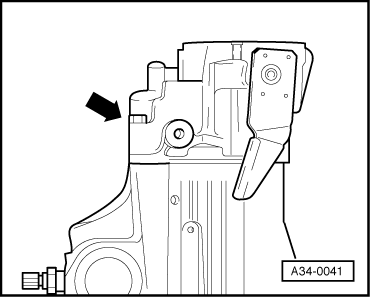

| Fit an M7 bolt -1- longer than the originals, into the retaining plate The input shaft should be slightly above its position, resting on tool -U-40007-. |

| –

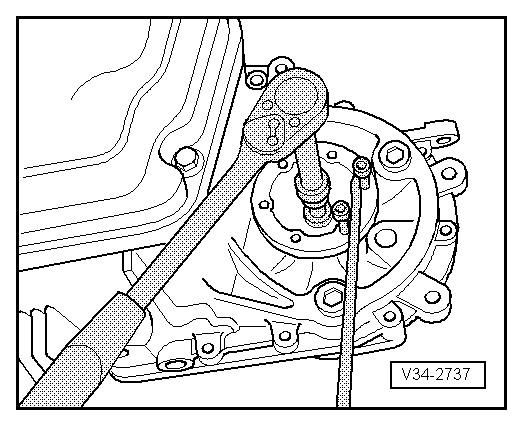

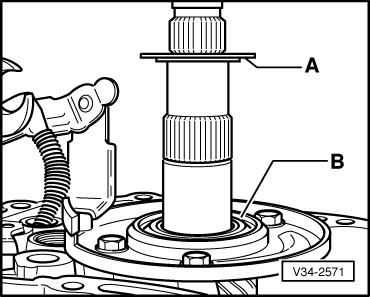

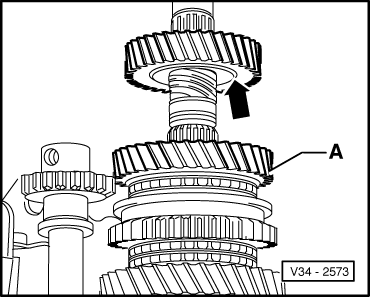

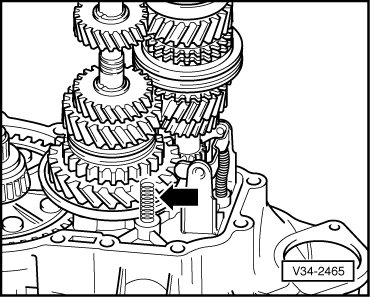

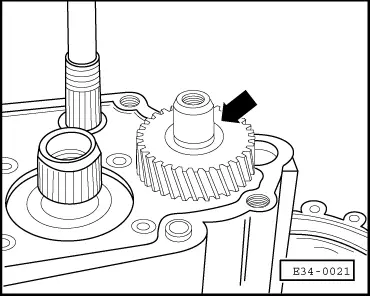

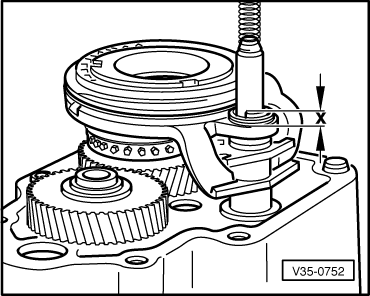

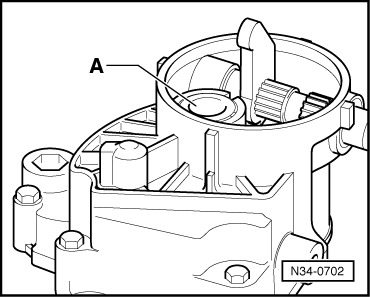

| Hit the geabox casing lightly with the plastic hammer, holding the coupling rod at the same time, until the bearing is partially fitted. |

| –

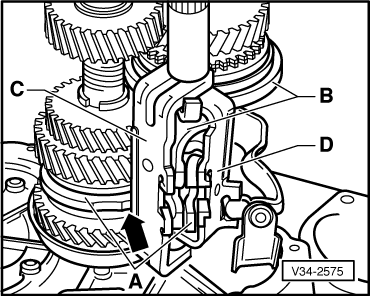

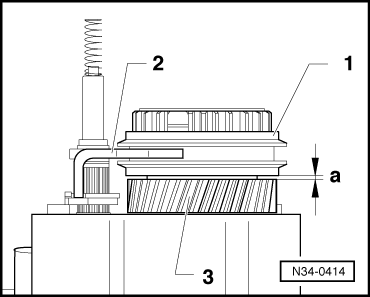

| Fit the bolts -2- to secure the tensioning plate and take the gearbox casing to its position. |

| –

| Fit the gearbox casing. |

| –

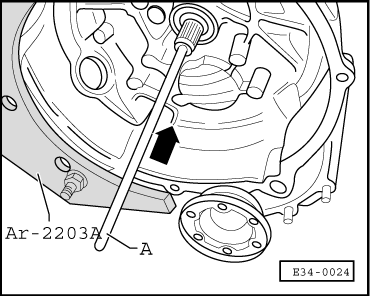

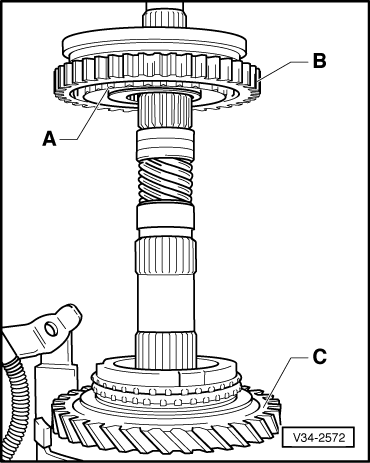

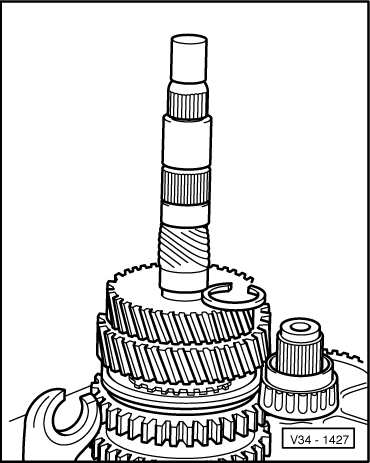

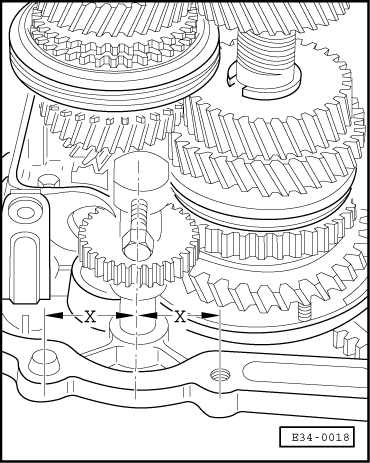

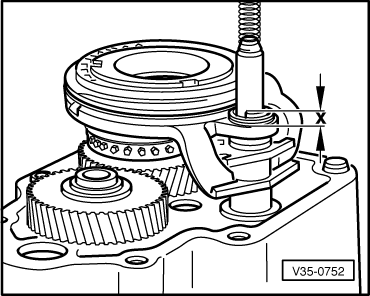

| Loosen tool -U-40007- support so that the input shaft moves to its position. |

| –

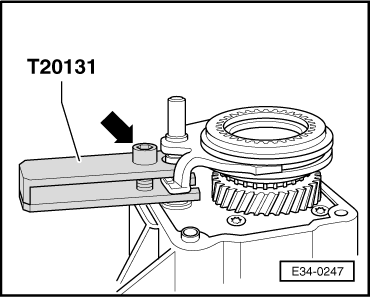

| Bolt up the reverse gear shaft. |

| –

| Tighten the hexagon bolts that secure the gearbox casing to 25 Nm. |

| –

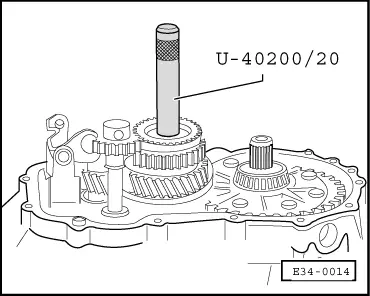

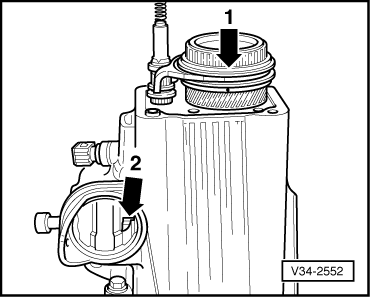

| Remove the M7 bolt from the ball bearing retaining plate. |

| –

| Re-tighten the ball bearing retaining plate bolts to 15 Nm. |

|

|

|

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!