| –

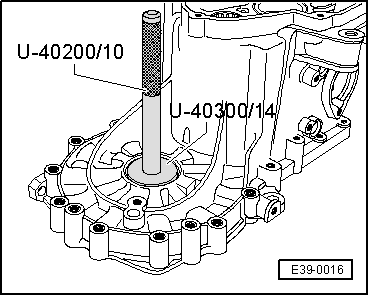

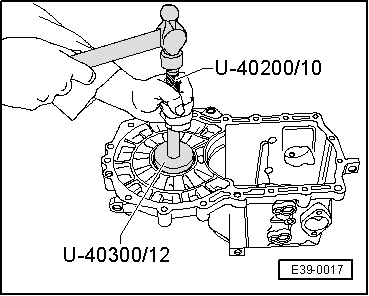

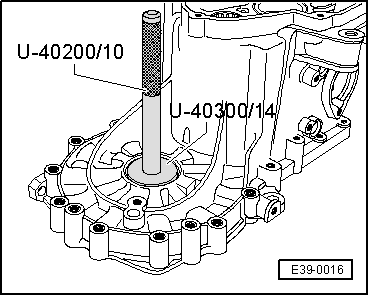

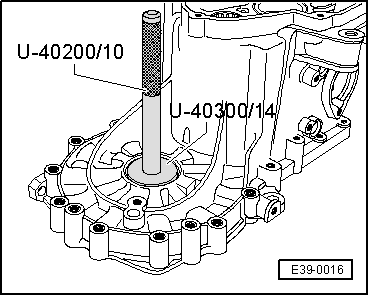

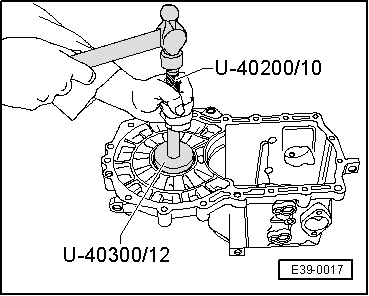

| Remove the outer roller bearing track from the differential, in the gearbox and clutch housing, with adapter -U 40200/10- and adapter -U 40300/14-. |

Note | t

| The procedure and tools needed to remove the secondary shaft rear bearings outer tracks, are identical in the gearbox casing and the clutch housing. |

| t

| To remove outer track of clutch casing, first remove socket for right articulation flange seal → Chapter, Gearbox housing and clutch housing: repairs. |

| t

| The roller bearings and their corresponding outer tracks are matched pairs. Do not mix with other bearings. |

|

|

|

Note

Note

Note

Note

Note

Note