| –

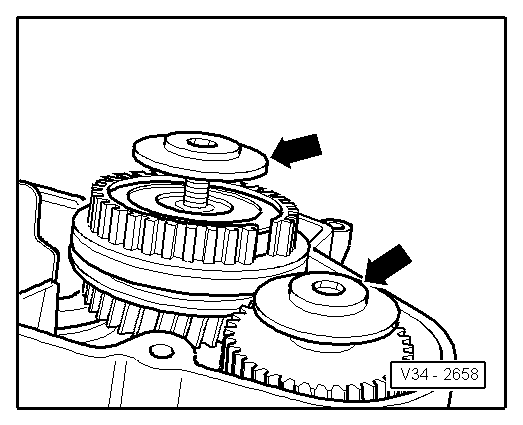

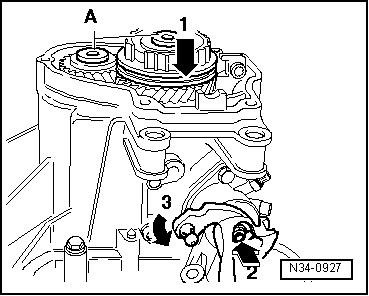

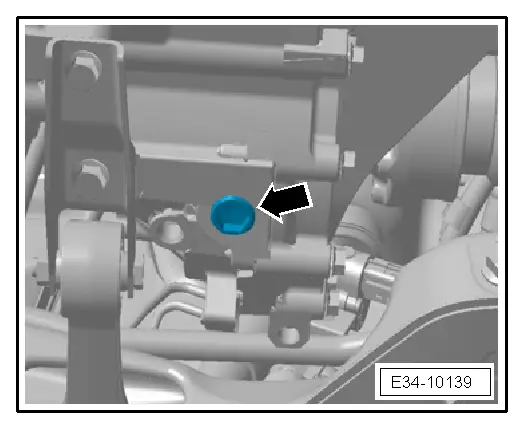

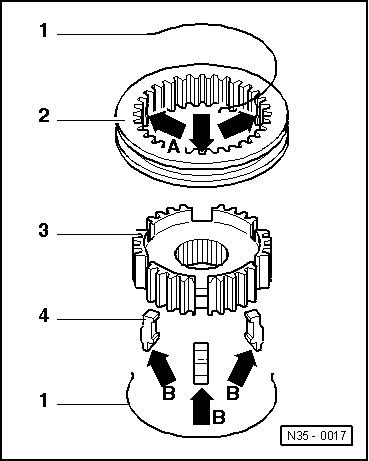

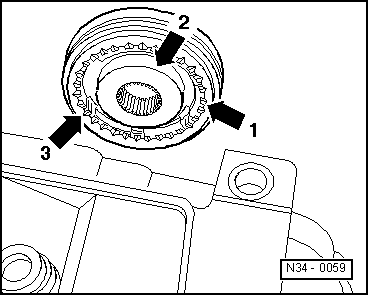

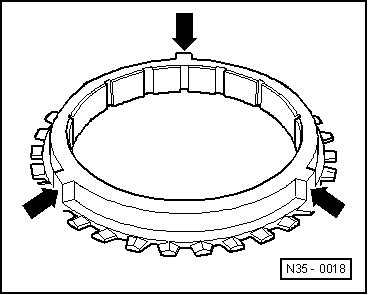

| 5. Gear engaged. Loosen bolt -1-. Press the mobile sleeve and the gear mouth in the direction of the -arrow-; then tighten the bolt -1- to 25 Nm. |

| l

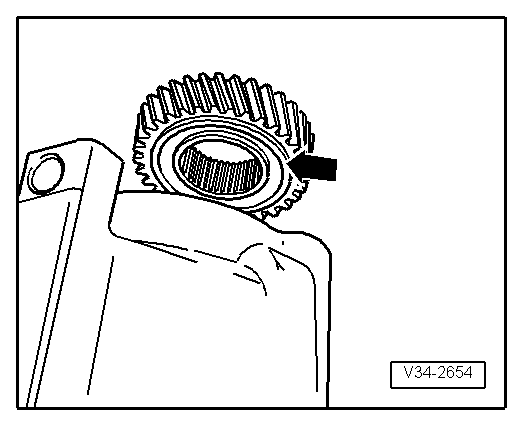

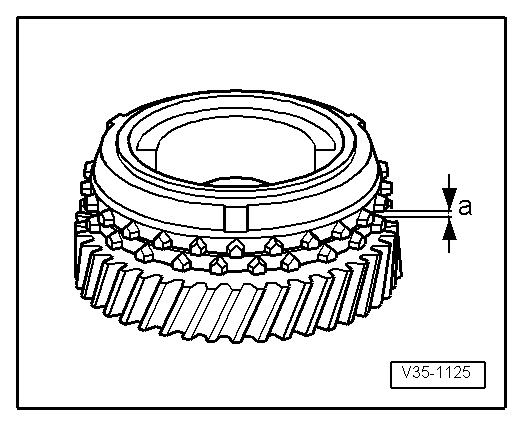

| Control measurement: Between the mobile sleeve and the mobile pinion, a thickness gauge of 0.2 mm cannot be inserted. If necessary, repeat the adjustment process. |

| –

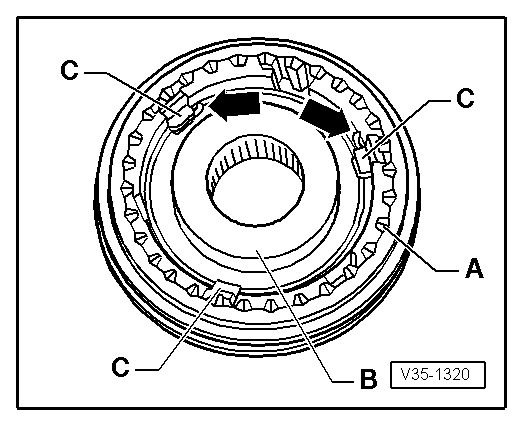

| Shift out of 5th gear. The sleeve must be situated in neutral position and the synchro ring must turn freely in this position. |

| –

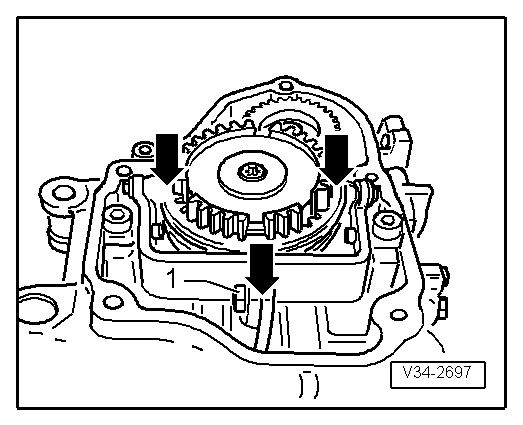

| Shift through all gears. |

| –

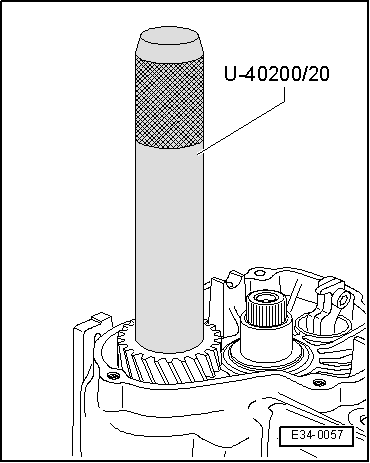

| Install the gasket and gearbox casing cover. |

| –

| Tighten the bolts to secure the gearbox casing cover to a torque of 10 Nm. |

|

|

|

Note

Note

Note

Note