Leon Mk1

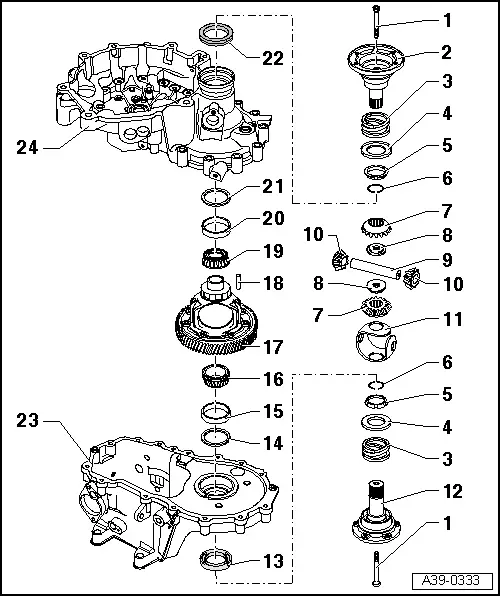

| Differential: assembly overview |

Note

Note| t | Heat the inner ring of the roller bearing to 100 ºC before fitting. |

| t | Replace both conical roller bearings together. |

| t | Adjust the differential whenever the roller bearings, differential casing, gearbox casing or clutch housing are replaced → Chapter. |

| 1 - | 25 Nm conical bolt |

| q | Screw in with threaded element → Item |

| 2 - | Right hand side flanged shaft |

| q | Do not mix up with the left hand side shaft |

| 3 - | Flanged shaft compression spring |

| q | Installed behind the flanged shaft |

| 4 - | Attack washer |

| q | Installation position: the collar faces the spring |

| 5 - | Conical ring |

| q | Installation position: conical side facing the differential casing |

| 6 - | Circlip |

| q | Keep the following in position: conical ring, shim and pressure spring for flanged shaft when it is dismantled |

| 7 - | Planet gear |

| q | Installing → Fig.. |

| 8 - | Threaded component |

| q | Installing → Fig.. |

| 9 - | Planet gear shaft |

| q | To remove, cut the tension sleeve → Item |

| q | Installing → Fig.. |

| 10 - | Planetary gears |

| q | Installing → Fig.. |

| 11 - | Set of thrust washers |

| q | Fit with gear oil. |

| q | Complete modified thrust washer assembly → Fig. |

| q | Allocation → Parts catalogue |

| 12 - | Left hand side flanged shaft |

| q | With dust guard plate |

| q | Do not mix up with the right hand side shaft |

| 13 - | Left flanged shaft seal: |

| q | The right hand side and left hand side have different diameters |

| q | Replacement with gearbox installed → Chapter |

| 14 - | S1 shim |

| q | For differential |

| q | immer 1 mm in dick |

| 15 - | Outer track, roller bearing |

| q | Remove → Fig. |

| q | Insertion → Fig. |

| 16 - | Inner ring of conical roller bearing socket |

| q | Releasing → Fig. |

| q | Insertion → Fig. |

| 17 - | Differential casing |

| q | With the wheel drive shaft riveted gear |

| q | Matched to the secondary shaft; these must be replaced together |

| q | Complete modified thrust washer assembly → Fig. |

| q | Allocation → Parts catalogue |

| 18 - | Elastic pin |

| q | To secure the satellite shaft |

| q | Extract the securing sleeve |

| 19 - | Inner ring of conical roller bearing socket |

| q | Releasing → Fig. |

| q | Insertion → Fig. |

| 20 - | Outer track, roller bearing |

| q | Releasing → Fig. |

| q | Insertion → Fig. |

| 21 - | S2 shim |

| q | For differential |

| q | Determine thickness → Chapter |

| 22 - | Left flanged shaft seal: |

| q | The right hand side and left hand side have different diameters |

| q | Replacement with gearbox installed → Chapter |

| 23 - | Gearbox |

| 24 - | clutch housing |