| –

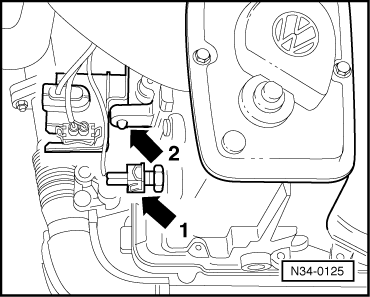

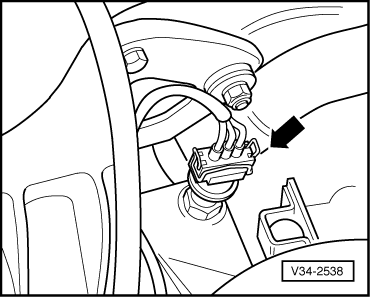

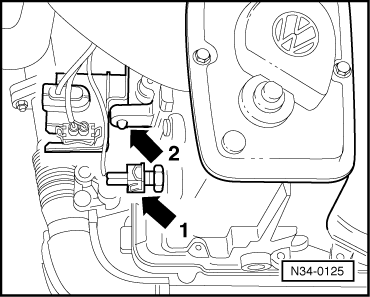

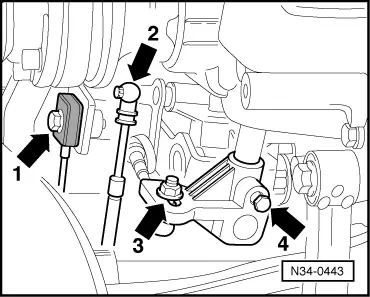

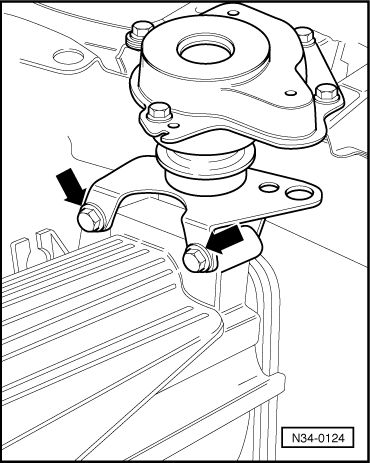

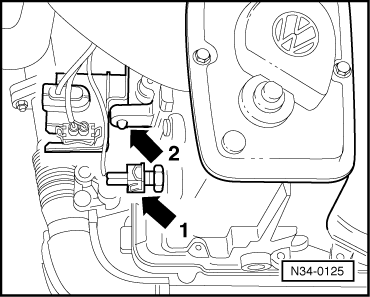

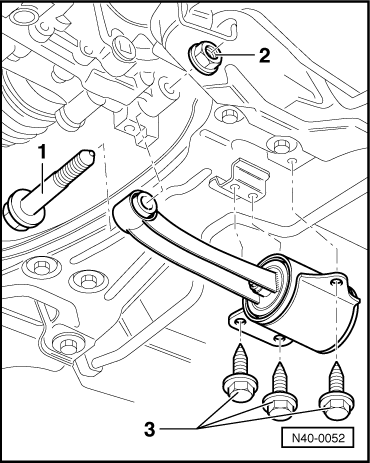

| Unbolt the cable and connector bracket from the gearbox -arrow 2-. |

| –

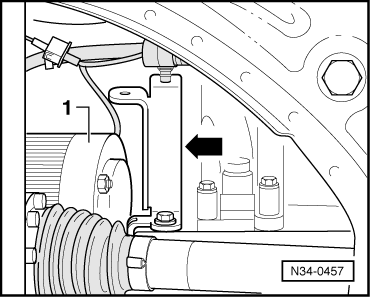

| Separate the reversing light connector -arrow 1-. |

| –

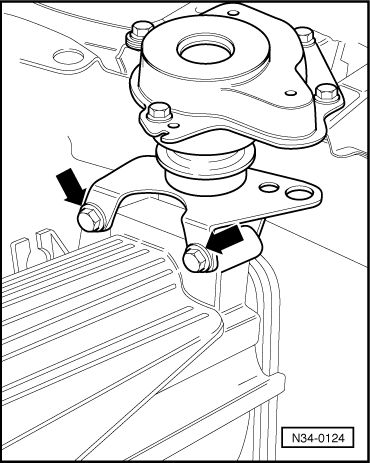

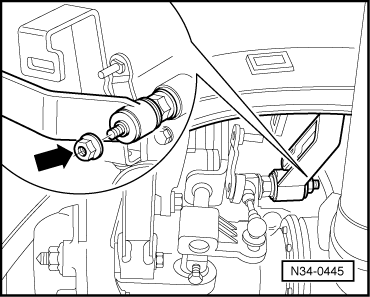

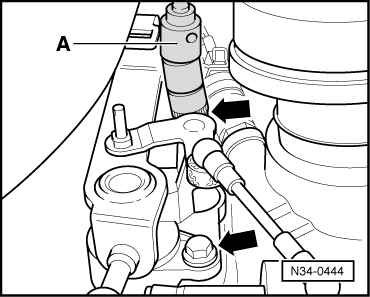

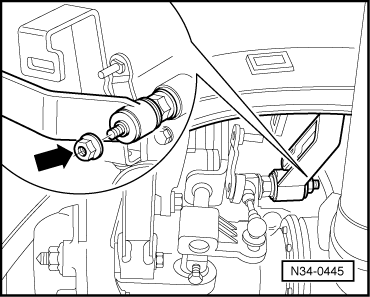

| Unbolt the earth cable from the engine to gearbox bolt. |

| –

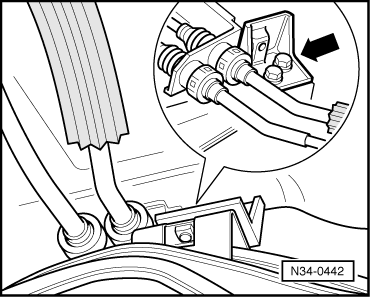

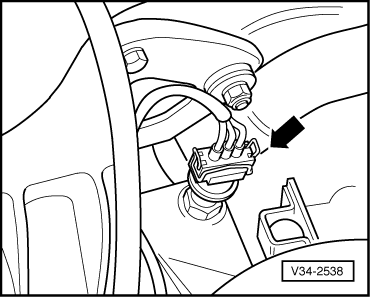

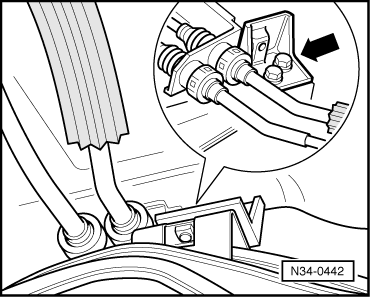

| Remove the cable guide from its gearbox fittings. |

| –

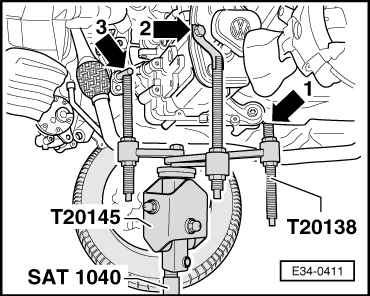

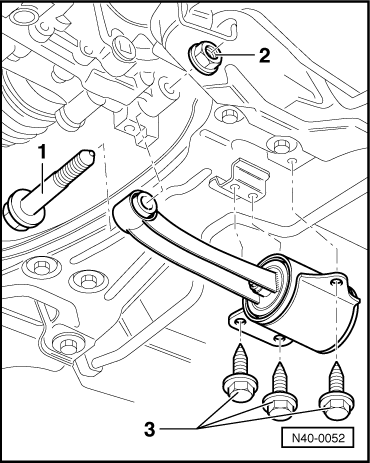

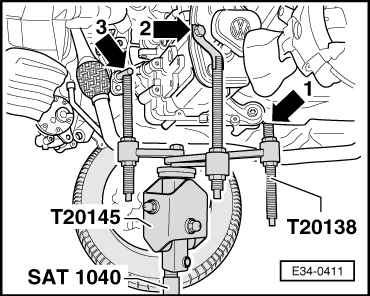

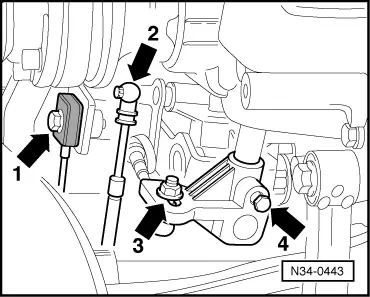

| Remove the upper bolts that secure the engine to the gearbox. |

| –

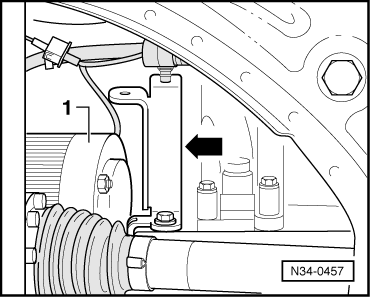

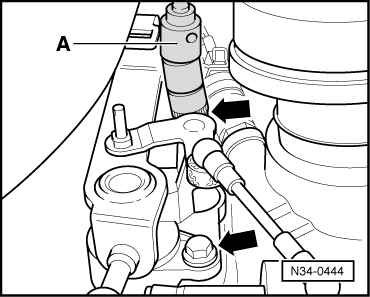

| Remove the drive shafts from the gearbox flanges using the correct spanner from tool Kit XZN -U-40020-. |

| –

| Turn steering towards the left completely. |

| –

| Hold the left-hand driveshaft as high as possible and secure it conveniently, taking care not to damage it. |

|

|

|

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!