Leon Mk1

| Clutch: repair |

| Assembly chart |

Note!

Note!| t | Always replace clutch plates and clutch presses that have loose or damaged rivets. |

| t | When replacing, assign the clutch plate and press according to the Replacement Parts Microfiche. |

| t | For working on the clutch, it is necessary to dismount the vehicle's gear box differential. |

| 1 - | Engine flywheel |

| q | When fitting the clutch plate, check that the centering pins are firmly set. |

| q | The contact surface with the clutch plate should be clean of oil and grease and without gashes or grooves. |

| q | Dismounting and assembly of the engine flywheel → Rep. Gr.13 of the corresponding engine |

| 2 - | Clutch plate |

| q | When replacing, assign according to the Replacement Parts Microfiche. |

| q | Lightly grease the strias. |

| q | Assembly position: the spring cage should face the clutch plate. |

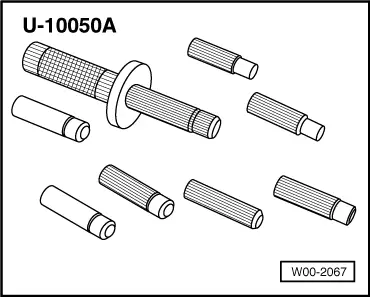

| q | Clutch plate centering → Fig. |

Note!

Note!| Clean the strias of the primary shaft and the clutch plate. Remove the rust from used clutch plates. Apply a fine layer of -G 000 100- grease on the strias of the primary shaft. With a to-and-fro movement, move the clutch plate on the primary shaft until it gently slides. Remove any excess grease. |

| 3 - | Clutch plate |

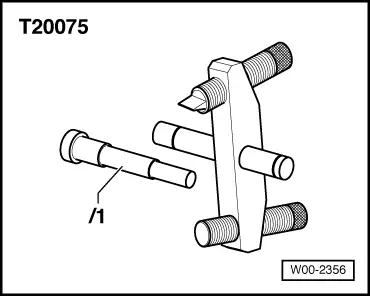

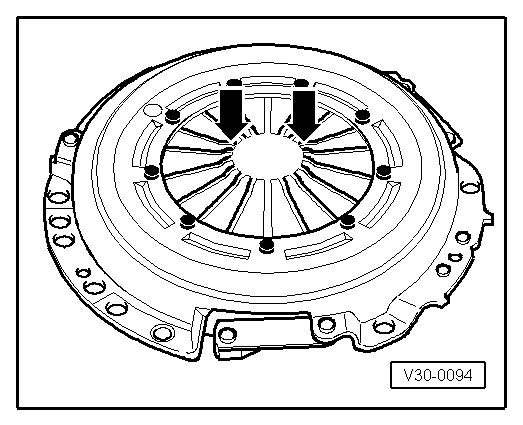

| q | Dismounting and assembly → Fig. |

| q | Check the edges of the diaphragm → Fig. |

Note!

Note!| Clutch plates are greased and protected against rust. Clean only the clutch plate contact surface of any grease or oil, otherwise the working life of the clutch will be reduced. |

| 4 - | Screw, 20 Nm |

|

|

|

Note!

Note!

|

|

|

|