| –

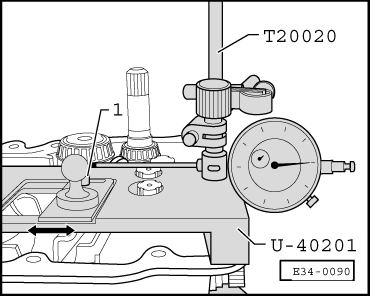

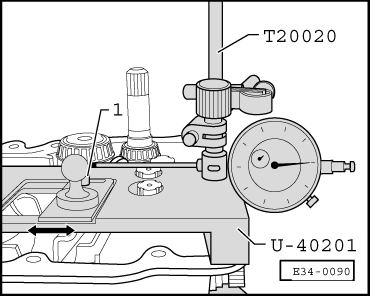

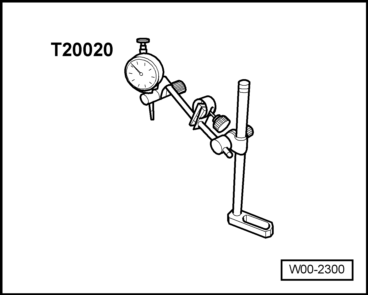

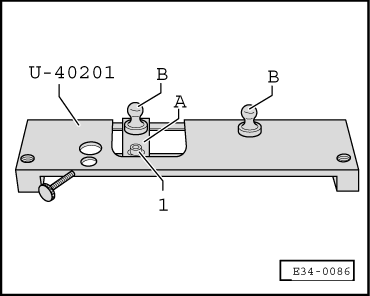

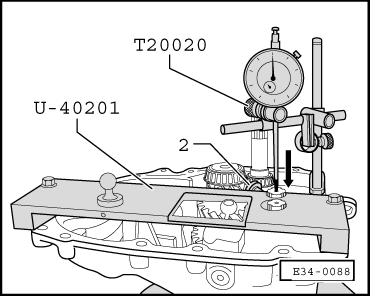

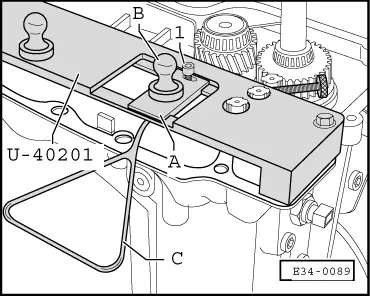

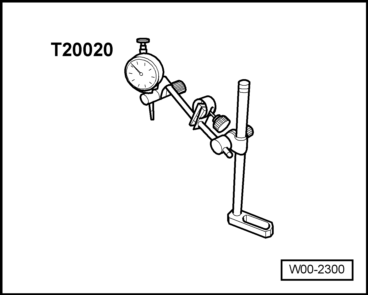

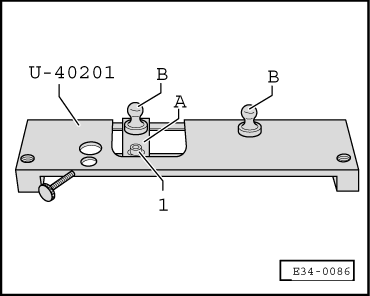

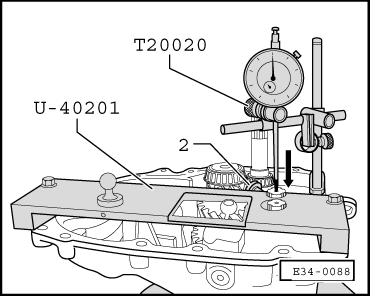

| Set tool -T20020- with a tester on top of tool -U-40201-. Put the end of the tester on one side of the round head -B-, with a pretension of 1mm. |

| –

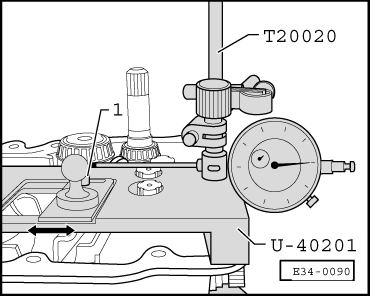

| Move the round head to one side and adjust the tester to “0”. |

| –

| Move the round in the opposite direction again and note the reading in the tester (example: 0.60 mm). |

| –

| Calculate the mean value for the range of displacement of the selector finger by dividing the value of the previous measurement by two: |

| –

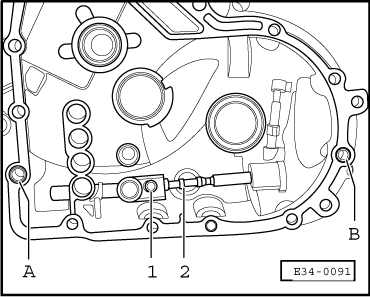

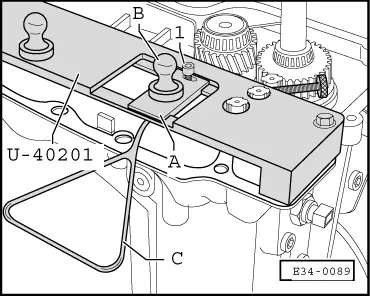

| Secure the slider with the screw -1- in the position of the value obtained previously (in this case, 0.30 mm). |

| –

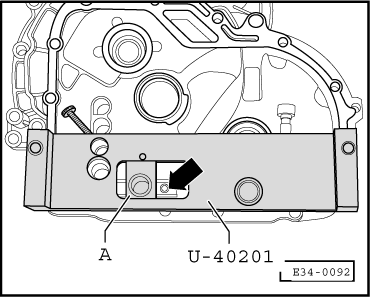

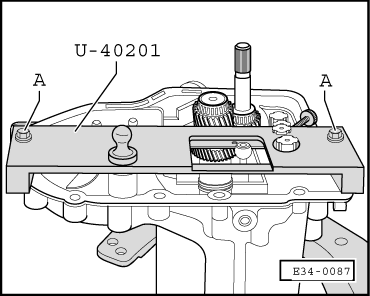

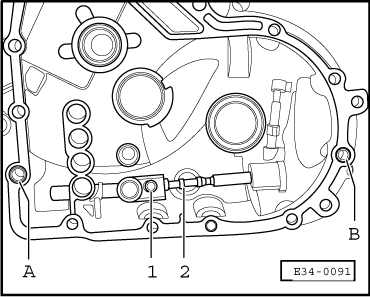

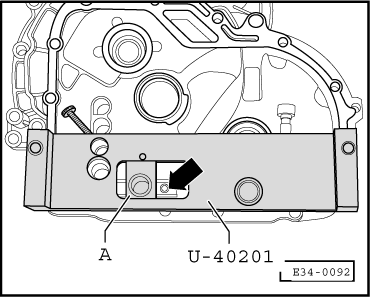

| Remove the tool -U-40201- from the gearbox casing. |

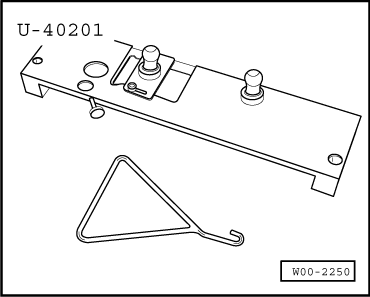

Note! | Do not alter the position of the components of tool -U-40201-. This would give the wrong adjustment for the selector finger and guide collar. |

|

|

|

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!