| t

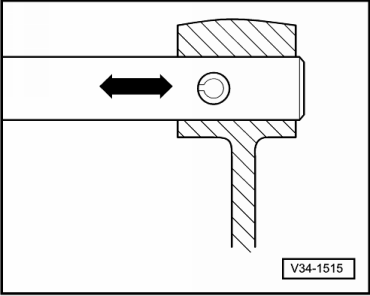

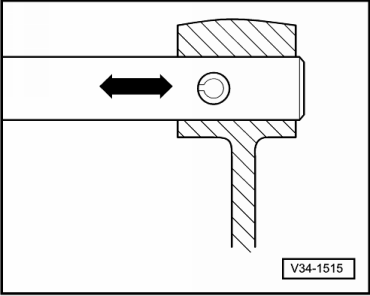

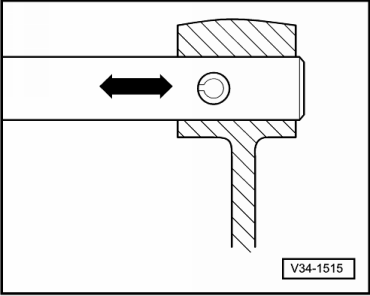

| When assembling the flexible guide pins, their slot must be positioned longitudinally to the direction of the drive, as shown in the figure. |

| t

| Always loosen and tighten bolts and nuts in diagonal order when attaching covers and casings. With delicate parts, such as the clutch press, for example, do not tilt them. Carry out the operation gradually. |

| t

| The stated tightening torque levels refer to nuts and bolts that are unoiled. |

| t

| Self-locking bolts and nuts must always be replaced. |

| t

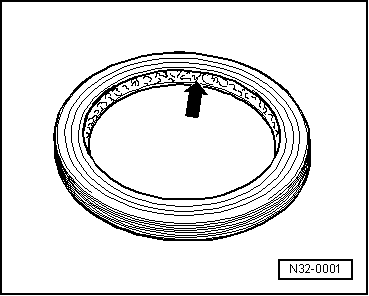

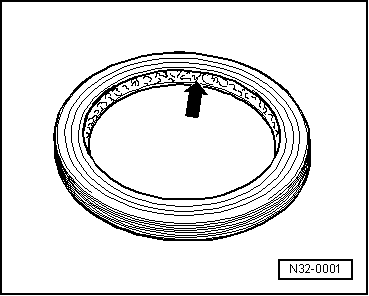

| Needle bearings must be assembled with the thickest side of the plate facing towards the assembly axle-tool. |

| t

| All bearings for the gearbox must be lubricated with gear oil before being put into place. Take special care when oiling them because of the friction torque measurements. |

| t

| All bearings on the same shaft must be replaced together. Use parts made by the same manufacturer as much as possible. |

| t

| Bearings should first be heated to a temperature of approximately 100°C before being put into place. Use the -SAT 1416- electrical blower and the -SAT 4002- digital thermometer for checking the temperature. |

| t

| Do not confuse nor exchange the outer bearing rings of similar size; the bearings go in pairs. |

| t

| The thickness of the adjusting washers should be checked before they are assembled by measuring them on the outside at different points with a micrometer. |

| t

| The availability of washers with different tolerance levels permits the precise thickness of the required washer to be found. |

| t

| Washers must not have rough edges or defects. |

| t

| Only assemble adjusting washers that are in perfect condition. |

| t

| Do not mix together synchroniser rings from different gears. If they have to be used again, use them on the same gear as before. |

| t

| Check them for wear and replace if necessary. |

| t

| Lubricate well with gear oil when assembling. |

| t

| Before being assembled, clean very carefully. They must first be heated to a temperature of approximately 100°C. Use the -SAT 1416- electrical blower and the -SAT 4002- digital thermometer for checking the temperature. |

| t

| New gearbox code letters have been introduced along with a new gear mineral oil API API GL4 SAE 75W in accordance with standard TL 521 78. This type of oil can only be used in gearboxes for which it is specified, and should never be used is gearboxes which use the previous oil API GL4 SAE 75W90 in accordance with standard TL 521 57 (synthetic oil). |

| Oils with different denominations and standards should never be mixed as this modifies the properties of the lubricants. |

|

|

|