| t

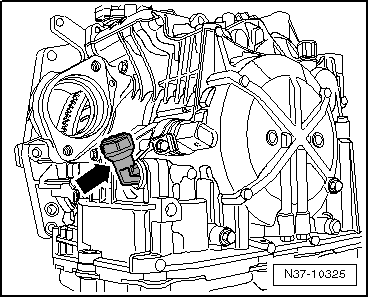

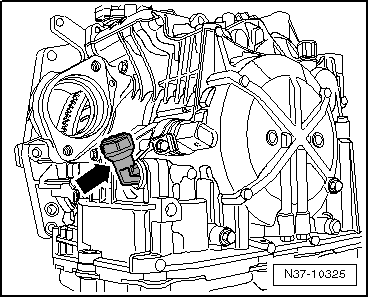

| After fitting, check the ATF fluid level and top up if necessary |

Caution | Treat oil with care. Dispose of extracted oil with respect to the environment. Remember that one drop of oil can contaminate 1000 litres of drinking water. |

|

| t

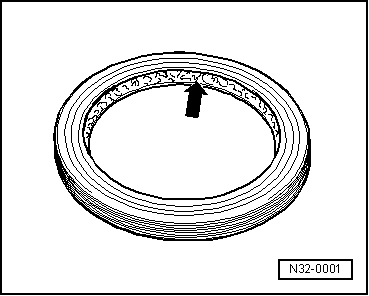

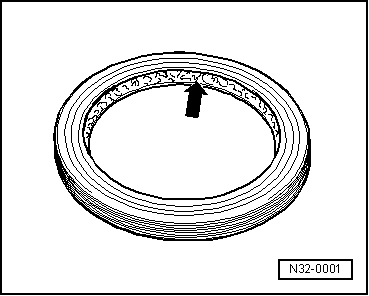

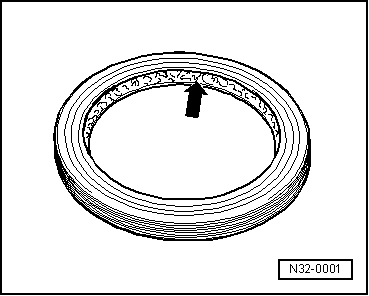

| Do not over expand the securing rings; replace them if necessary. |

| t

| Securing rings must be well seated in the groove. |

| t

| The bolts are removed in reverse order to the tightening sequence. |

| t

| The nuts and bolts for securing covers and casings, when not otherwise specified, must be removed is stages and diagonally. |

| t

| Renew self-locking nuts. |

| t

| The threads of those bolts fitted using a fixing agent must be cleaned using a wire brush. Next, insert the bolts with the fixing agent → Spare parts catalogue. |

| t

| Specified torques given are for unlubricated nuts, bolts and screws. |

| t

| Use a threaded connection to clean the remains of the fixing agent from all the threaded sockets in which the self-locking bolts are to go Otherwise, there is a risk of the bolts breaking when next removed |

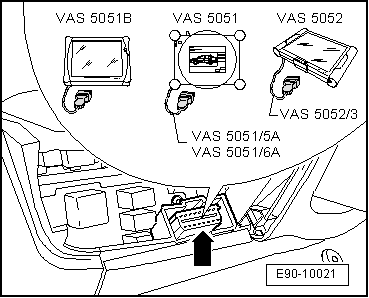

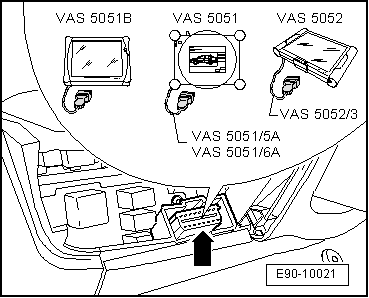

| You are bound to have received an electric shock at some time on touching metal objects, caused by the electrostatic charge of the human body. This static charge may cause errors in the functioning of the electrical components in the gearbox and the gearbox operation mechanism if touched. |

| –

| Therefore, we recommend touching any earthed object (for example, a waterpipe or lifting platform) before working with electronic components. Do not directly touch the contacts or electrical components which are „disconnected“. |

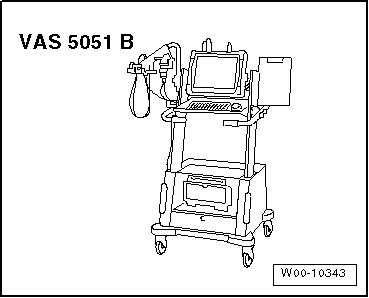

| Guided fault location, vehicle self-diagnosis and measurement module |

|

|

|