Leon Mk1

|

|

|

|

|

|

|

|

|

|

|

|

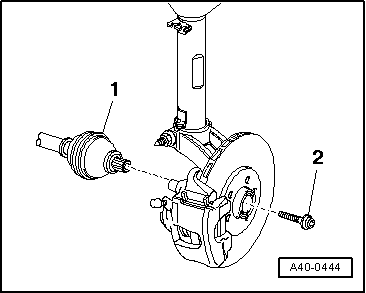

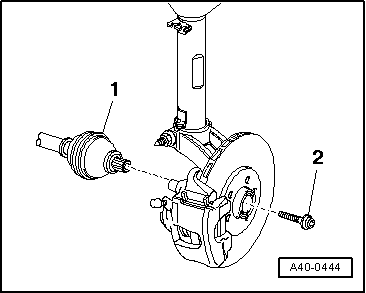

| Component | Nm | |

| Flanged shaft to differential | 25 | |

|

|

|

|

|

|

|

|

|

|

|

|

| Component | Nm | |

| Flanged shaft to differential | 25 | |