| –

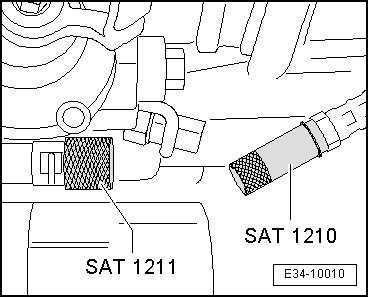

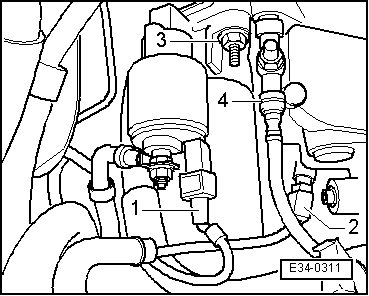

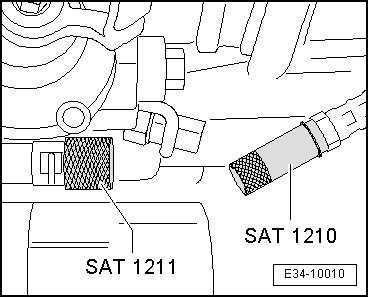

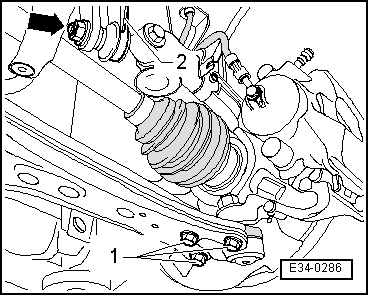

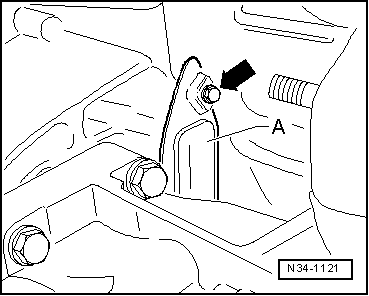

| Seal off the pressure conduits of the clutch circuit using the clutch circuit seal (male) -SAT 1211- on the side of the clutch slave cylinder, and using the clutch circuit seal (female) -SAT 1210- on the side of the clutch master cylinder. |

WARNING | Do not depress clutch pedal after removing slave cylinder. |

|

Note | t

| Brake fluid is toxic. It should not come into contact with the paintwork due to its corrosive effects. |

| t

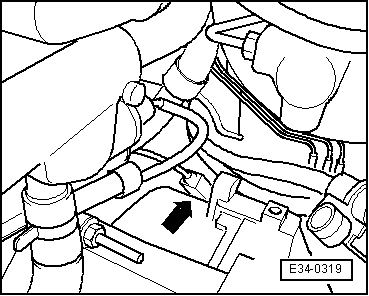

| When handling the brake fluid hoses, place a large protective cover or cloth with no loose threads under the clutch slave cylinder adaptor. |

|

|

|

Note

Note Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note

WARNING

WARNING