Leon Mk1

| Gearbox housing, operation mechanism, input shaft, secondary shaft, differential gear and gearbox forks: Removing and installing |

| Consult the equivalence table for tools and equipment according to applicability among Seat / VW / Audi / Skoda → Chapter. |

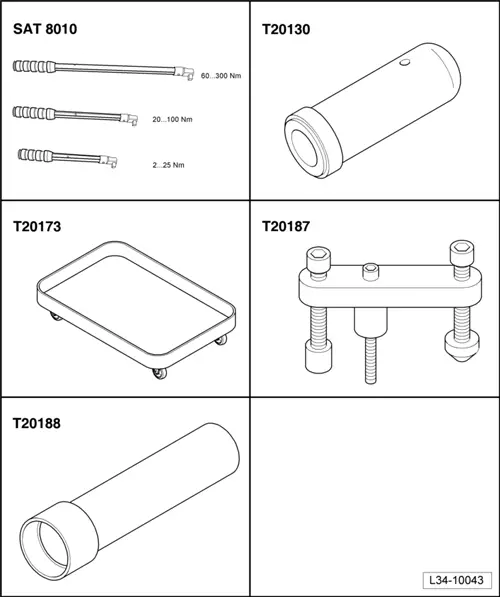

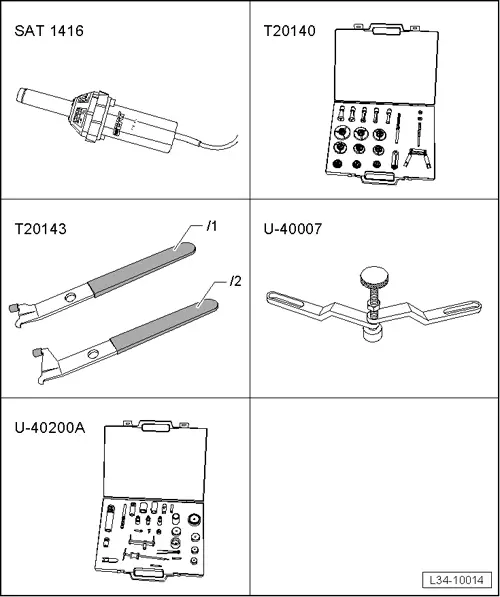

| Special tools and workshop equipment required |

| t | Torque wrench kit -SAT 8010-, see equivalent → Anchor |

| t | Tappet -T20130-, see equivalent → Anchor |

| t | Collecting tray -T20173-, see equivalent → Anchor |

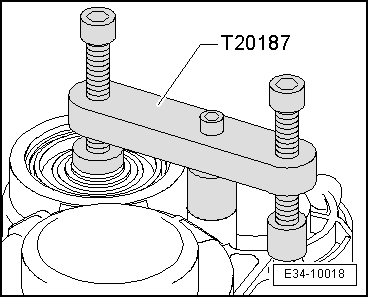

| t | Counterhold -T20187-, see equivalent → Anchor |

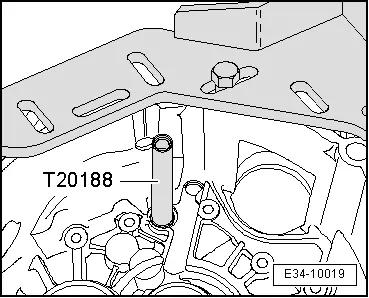

| t | Tappet -T20188-, see equivalent → Anchor |

| t | Hot air blower -SAT 1416-, see equivalent → Anchor |

| t | Digital thermometer -SAT 4002-, see equivalent → Anchor |

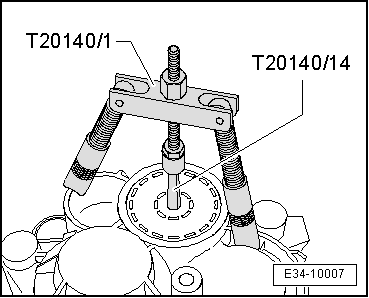

| t | Extractor kit -T20140-, see equivalent → Anchor |

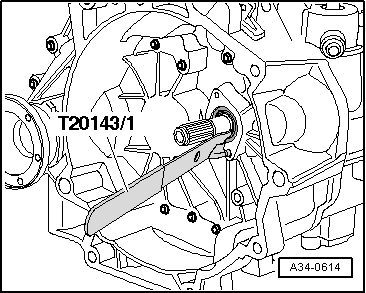

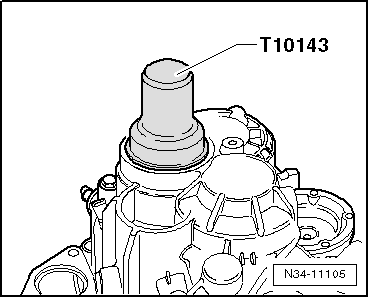

| t | Extraction lever -T20143-, see equivalent → Anchor |

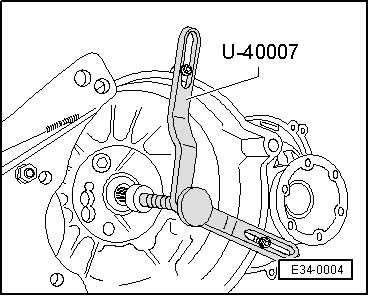

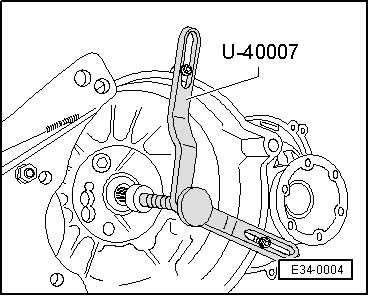

| t | Retention tool -U 40007-, see equivalent → Anchor |

| t | Kit (case) -U 40200A-, see equivalent → Anchor |

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note |

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|