| t

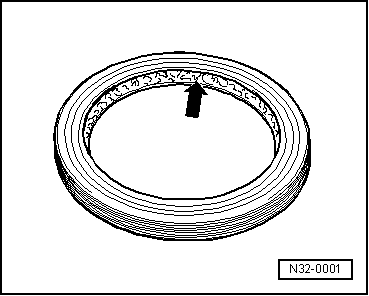

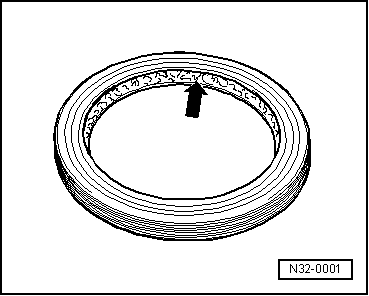

| Do not over-expand safety rings. |

| t

| The securing rings must be perfectly seated in their groove. |

| t

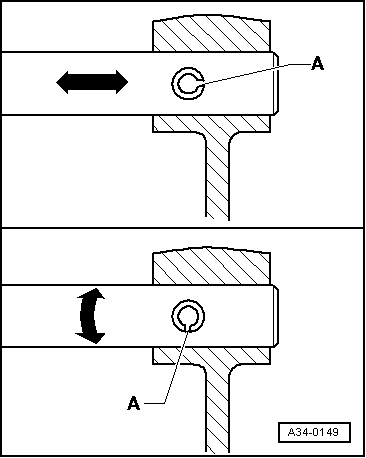

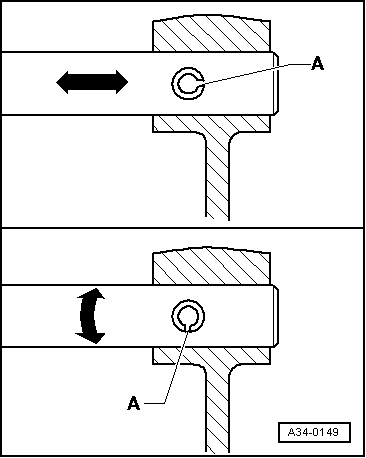

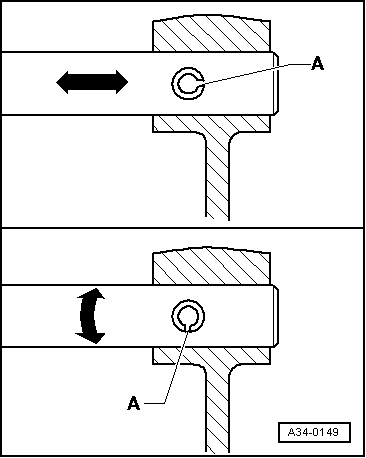

| Replace split pins. Installation position: the groove -A- is positioned lengthwise to the flow of the pressure -arrow-. |

| t

| Loosen bolts and nuts in reverse of tightening sequence. |

| t

| The bolts and nuts to be used to secure covers and casings must be released and tightened diagonally in stages when no tightening order is specified. |

| t

| Always replace self-locking nuts and bolts. |

| t

| The torque settings refer to non-oiled nuts and bolts. |

| t

| Threaded holes where there had been self-locking bolts or bolts with thread fixing agent must first be cleaned (for example, with a threading male). If this is not done, the bolts may break when removed again. |

| t

| In all bolted unions, ensure that supporting surfaces and bolts and nuts are only waxed after installation, if this is necessary. |

| t

| Install new roller bearings as supplied (without additional oiling). |

| t

| All bearings (apart from roller bearings) of the gearbox must be fitted lubricated with gear oil. |

| t

| Before fitting interior rings of roller bearings, first heat them to 100 ºC approx. Use the electric blower -SAT 1416-. When installing, they must be pressed in to their limit, without leaving axial play or rebound. |

| t

| The temperature can be measured with the digital thermometer -SAT 4002-. |

| t

| Do not confuse the outside and inside rings of the bearing with the rings from other bearings of the same size. |

| t

| Roller bearings fitted into one same shaft must be replaced together, using products of the same manufacturer. |

| t

| Position gear needle roller bearings with the stamped side (thicker plate) towards the mandrel to be fitted. |

| t

| Check shim settings at various points, using a micrometer. The existence of different tolerances allows the necessary shim thickness to be selected exactly. |

| t

| Check for burrs and damages. Install only perfect shims. |

| t

| Must not be swapped. Do not mix up synchroniser rings from different gears. |

| t

| Check for wear and replace if necessary. |

| t

| Fit them lubricated with gear oil. |

| t

| Before fitting pinions, they must be cleaned and heated to 100 ºC approx. Use the electric blower -SAT 1416-. |

| t

| The temperature can be measured with the digital thermometer -SAT 4002-. |

| t

| Check whether, after fitting, the mobile pinions of 1st ª to 6thª gear have slight axial play and move easily. |

| t

| When removing the gearbox, the clutch slave cylinder must be extracted without opening the piping system. |

| t

| If the clutch slave cylinder is removed together with the hydraulic pipe, do not press the clutch pedal. Otherwise, the slave cylinder piston will be expelled. |

| t

| Do not incline the pressure disk; loosen slightly in each passage and diagonally, the installation is done in the same way. |

| t

| To reduce the unpleasant smells of a burnt clutch, the clutch bell-housing must be thoroughly cleaned, along with the flywheel and engine at the side facing the clutch. |

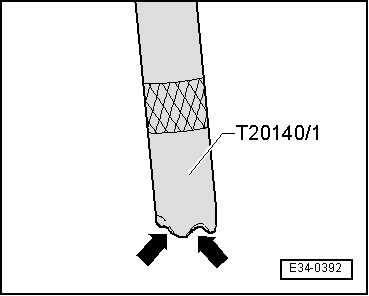

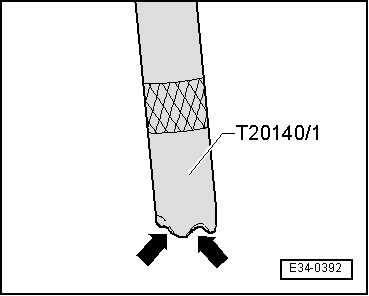

| Extraction of the outer roller bearing rings and the bearing bushes using the kit -T20140- |

| l

| Remove the outer rings of the conical roller bearings or the bearing bushes as follows: |

| –

| Measure (if possible) the internal diameter of the external ring of the roller bearing or the bearing bush. |

| –

| Select the appropriate clamp from the kit -T20140- noting the following: |

| l

| If the diameter measured is less than 30 mm: |

| –

| Fit the valve tappet for small clips /10 and the appropriate clip for internal diameters. |

| l

| If the diameter measured is greater than 30 mm: |

| –

| Fit the valve tappet /28 with the clip /29 and the appropriate grips for internal diameters. |

| –

| Screw nut /5 and washer onto the valve tappet. |

| –

| Place the tool on the outer ring of the roller bearing or the bearing bush and fit the threaded legs so that they are firmly secured. |

|

|

|

Note

Note

Note

Note