Leon Mk1

|

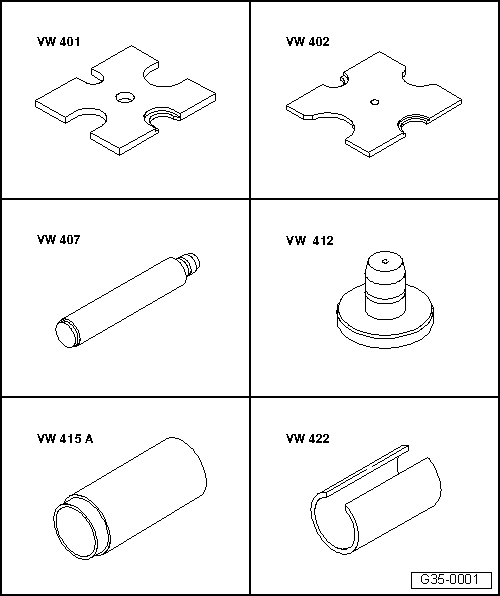

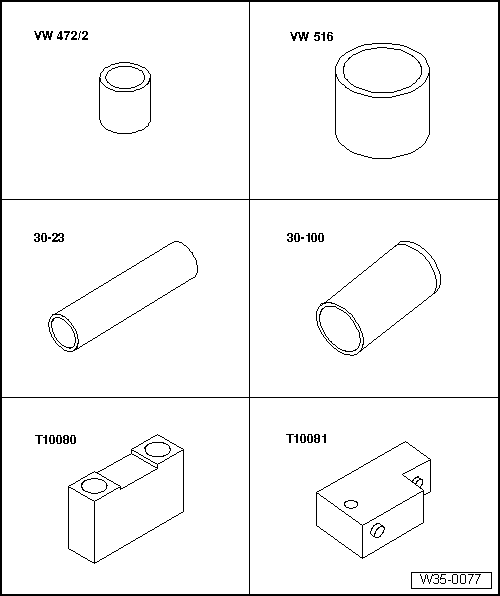

| Special tools and workshop equipment required |

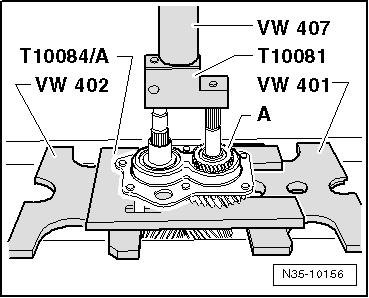

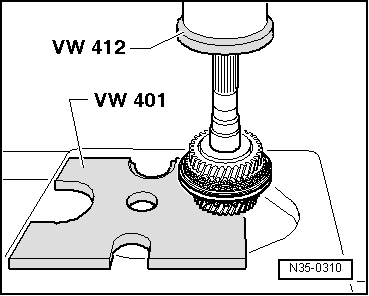

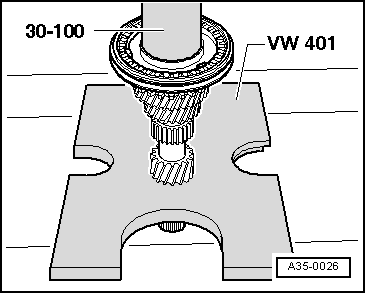

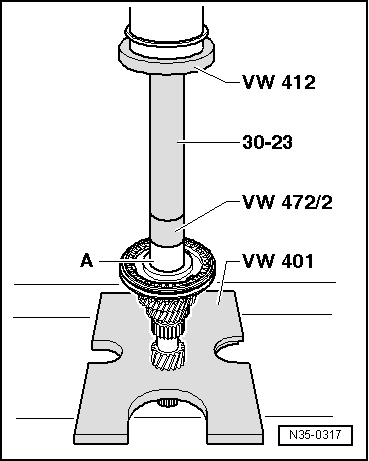

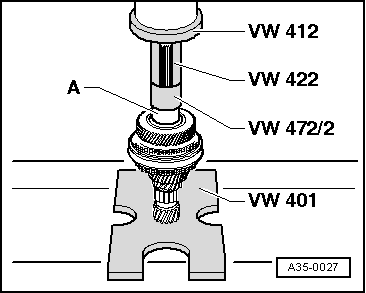

| t | Pressure plate -VW 401-, see equivalent → Anchor |

| t | Pressure plate -VW 402-, see equivalent → Anchor |

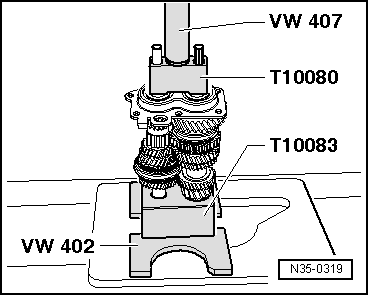

| t | Terminal crimper -VW 407-, see equivalent → Anchor |

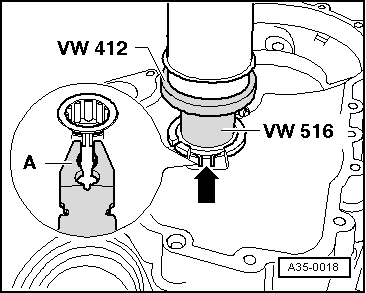

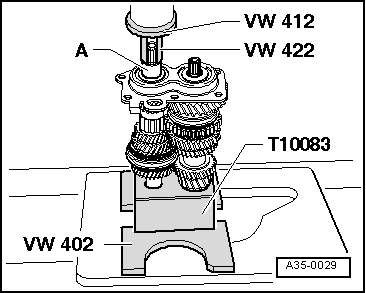

| t | Terminal crimper -VW 412-, see equivalent → Anchor |

| t | Tube element -VW 415 A- |

| t | Tube element -VW 422- |

| t | Spacer bush -VW 472/2- |

| t | Pipe section -VW 516-, see equivalency → Anchor |

| t | Locking plate -30-23- |

| t | Press tool -30-100- |

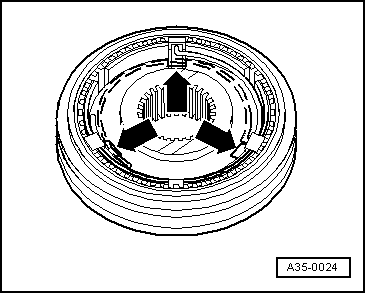

| t | pressure tool -T10080- |

| t | pressure tool -T10081- |

|

|

|

|

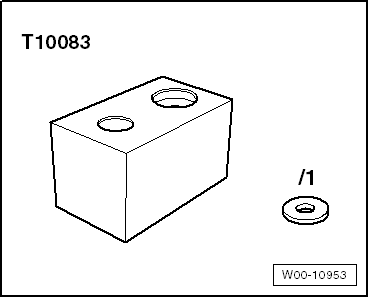

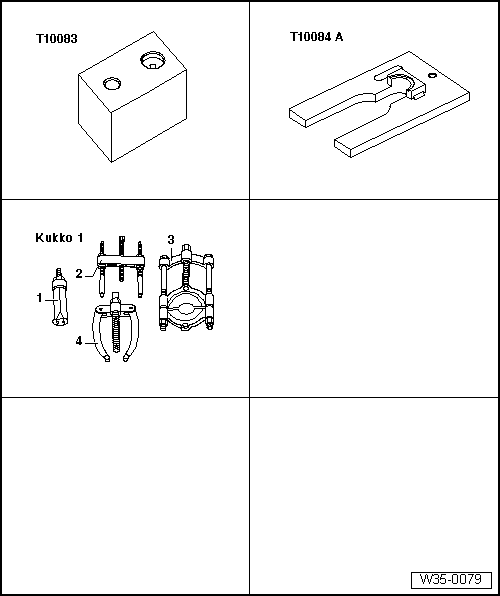

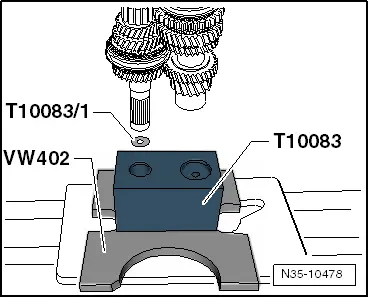

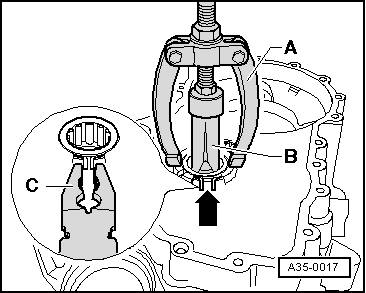

| t | Base for fitting -T10083- |

| t | Tightening plate -T10084 A- |

| t | -1-Interior extractor -Kukko 21/5- |

| t | -4-Support bracket -Kukko 22/2- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

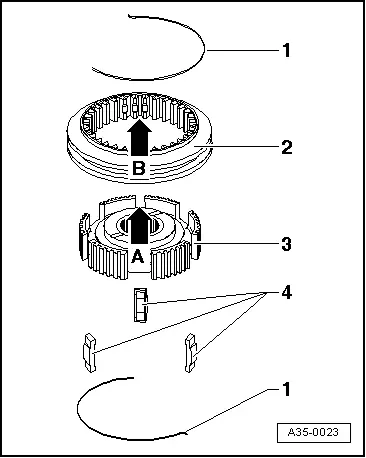

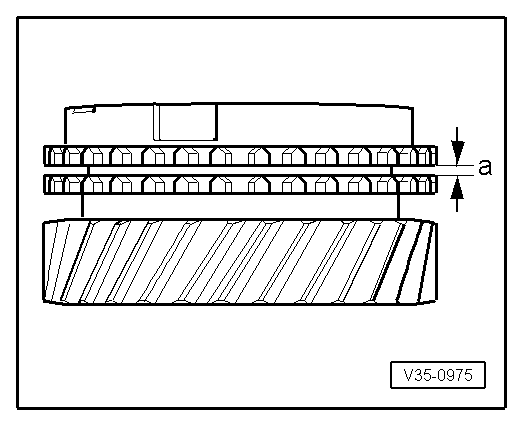

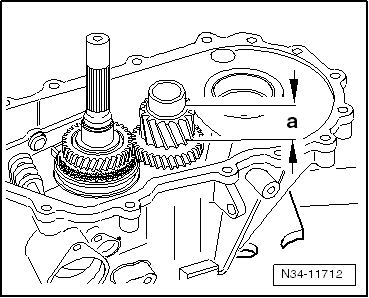

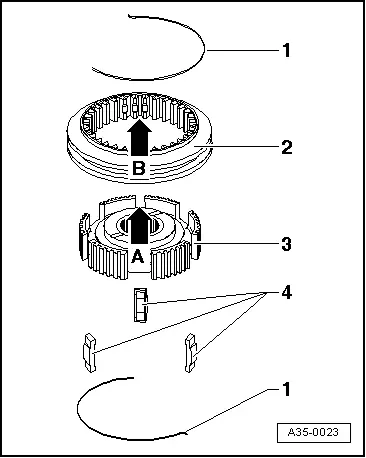

| Gap -a- | Installation dimension | Wear limit |

| 3., 4., 5. and 6th gear | 1.1 ... 1.7 mm | 0.5 mm |

|

|

|

|

|

|

Note

Note

|

|

| Measured value (mm) | Retaining ring thickness (mm) | Axial play (mm) |

| 0,05 … 0,14 | 2,0 | 0,05 … 0,15 |

| 0,15 … 0,24 | 2,1 | 0,05 … 0,15 |

| 0,25 … 0,34 | 2,2 | 0,05 … 0,15 |

| 0,35 … 0,44 | 2,3 | 0,05 … 0,15 |

| 0,45 … 0,51 | 2,4 | 0,05 … 0,10 |

Note

Note |

|

|

| Dimension -a- = 30.6 mm | |

| Insert shim -T10083/1- ⇒ next figure. |

|

|

|

|

|

|

|

|

|

|

WARNING

WARNING