Leon Mk1

|

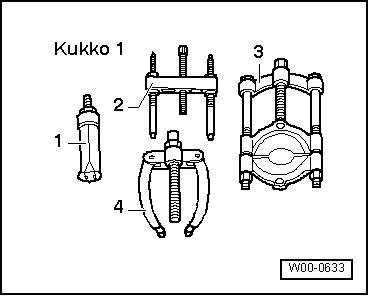

| Special tools and workshop equipment required |

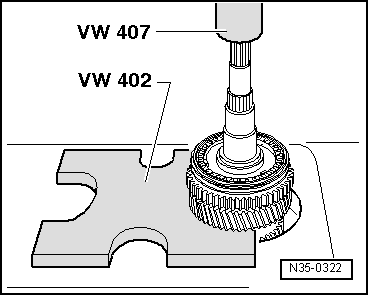

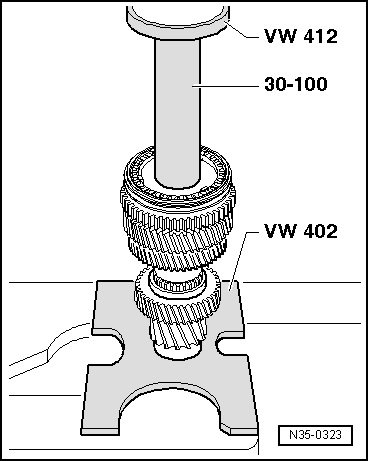

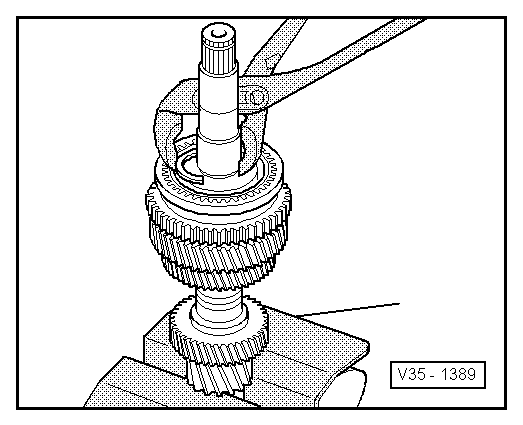

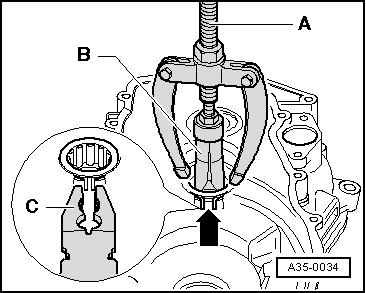

| t | Pressure plate -VW 402-, see equivalent → Anchor |

| t | Terminal crimper -VW 407-, see equivalent → Anchor |

| t | Tube element -VW 415 A- |

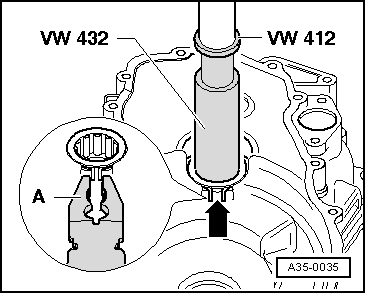

| t | pressure tool -VW 432- |

| t | Press tool -30-100- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

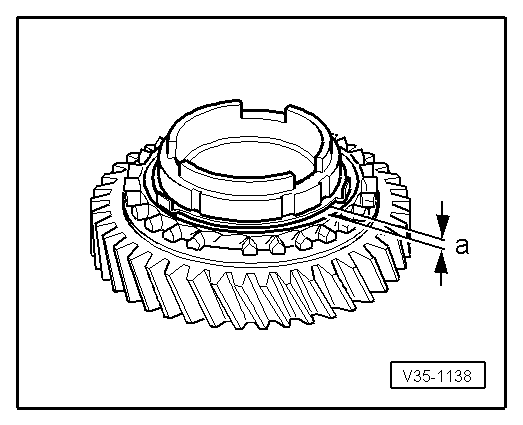

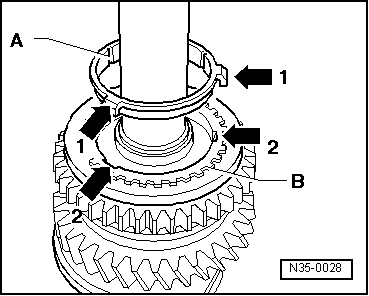

| Gap „a“ | Installation dimension | Wear limit |

| 1st and 2nd gears | 0.75...1.25 mm | 0.3 mm |

|

|

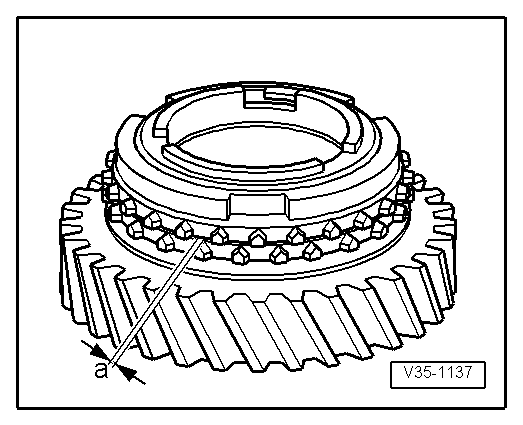

| Gap „a“ | Installation dimension | Wear limit |

| 1st and 2nd gears | 1.2 ... 1.8 mm | 0.5 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING

WARNING