Leon Mk1

| Dismantling and assembling 3rd and 4th gear clutch -K3- with turbine shaft |

| Special tools and workshop equipment required |

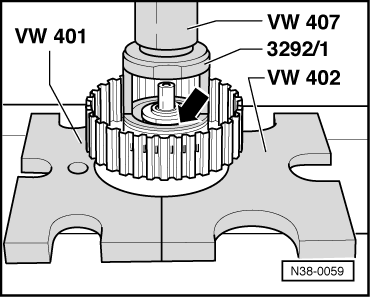

| t | Pressure plate -VW 401- |

| t | Pressure plate -VW 402- |

| t | Press tool -VW 407- |

| t | -3292/1- from fitting appliance -3292- |

| The clutch is only allowed to be dismantled for cleaning or when you are carrying out visual check. |

| Clutches -K1- and -K3- can be pressed together in some gearboxes. |

| Press -K1- off -K3- → Chapter |

| Press -K1- onto -K3- → Chapter |

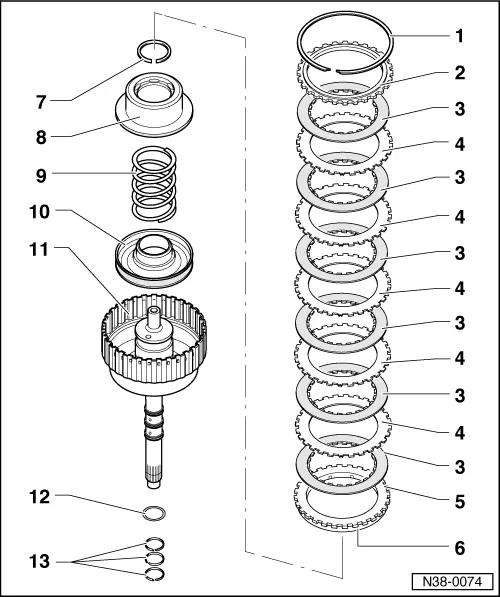

| 1 - | Circlip |

| q | Different thickness. |

| q | Marking after removing and inserting at same point. |

| 2 - | Pressure plate |

| q | Installing with stepped side facing circlip. |

| 3 - | Inner disc |

| q | Quantity → Chapter. |

| q | Before installing place in ATF for 15 minutes. |

| 4 - | Outer disc |

| q | Quantity → Chapter. |

| 5 - | Thrust plate |

| q | Installing with peened corrugated washer facing piston. |

| 6 - | Corrugated washer |

| q | Peened to thrust plate → Item. |

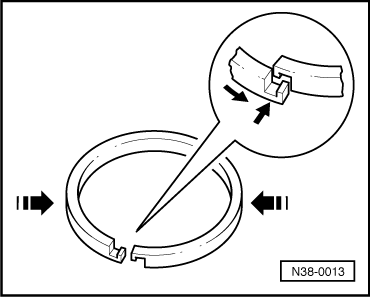

| 7 - | Circlip |

| q | Removing and installing → Fig.. |

| 8 - | Piston cap |

| q | Sealing lips are vulcanised to piston cap. |

| q | Moistening sealing lips with ATF before installing. |

| q | Turn piston cap slightly when installing. |

| q | When removing and installing press down and fit circlip → Item. |

| 9 - | Spring |

| q | Seating between piston and piston cap. |

| 10 - | Piston |

| q | Sealing lips are vulcanised to piston. |

| q | Moistening sealing lips with ATF before installing. |

| q | Turning piston slightly when installing. |

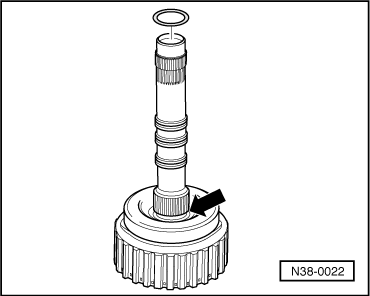

| 11 - | Clutch housing with turbine shaft |

| q | Height varies according to number of inner and outer discs. |

| 12 - | O-ring |

| q | Always renewing. |

| q | Installing → Fig.. |

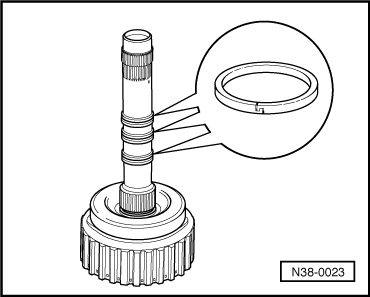

| 13 - | Piston ring |

| q | Checking that it is correctly located → Fig.. |

| q | Fitting → Fig.. |

|

|

|

|

|

|