Leon Mk1

|

|

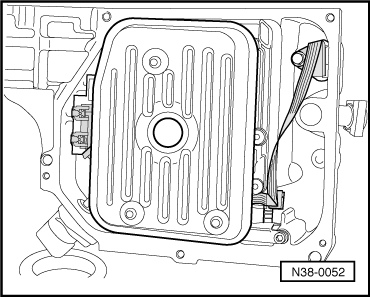

|

|

|

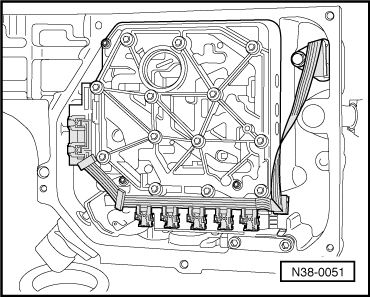

| t | The valve body or the conductor strip can also be removed when the gearbox is installed. |

| The conductor strip can be removed individually. |

| t | After reinstalling oil pan, check ATF level and top up → Chapter. |

| t | Always renew a valve body which is fouled or defective. |

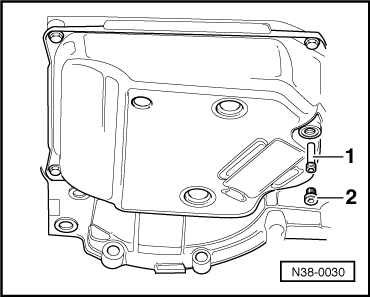

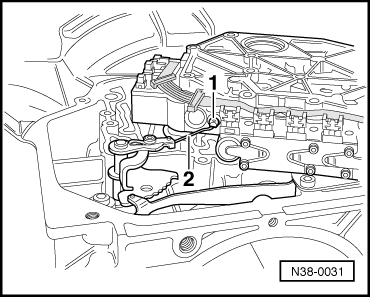

| 1 - | Plug |

| q | Always renewing oil seal → Fig.. |

| q | Checking ATF level and topping up → Chapter. |

| 2 - | Overflow pipe |

| q | Removing to drain ATF → Fig.. |

| q | Screwing in onto stop. |

| q | Checking ATF level and topping up → Chapter. |

| 3 - | Oil pan |

| 4 - | Bolt, 12 Nm |

| 5 - | Magnet |

| q | Inserting in the recess in oil pan. |

| 6 - | Spacer bush |

| q | Pressing into gasket. |

| 7 - | Seal |

| q | Always renewing. |

| q | Pressing spacer bushes into gasket. |

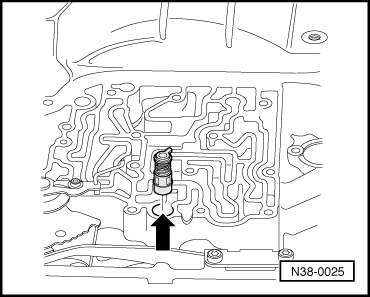

| 8 - | ATF strainer |

| q | Installing → Fig.. |

| 9 - | Bolt, 5 Nm |

| 10 - | Seal |

| q | Always renewing. |

| q | Inserting in valve body. |

| 11 - | Valve body |

| q | Removing → Fig.. |

| q | Installing → Fig.. |

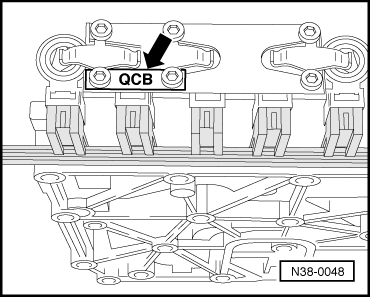

| q | Identification → Fig.. |

| q | Inserting seal → Item. |

| 12 - | Bolt, 10 Nm |

| 13 - | O-ring |

| q | For cable lead-through. |

| q | Always renewing. |

| 14 - | Conductor strip with connector for solenoid valves |

| q | With cable lead-through and connector. |

| q | Can also be removed and installed with gearbox installed. |

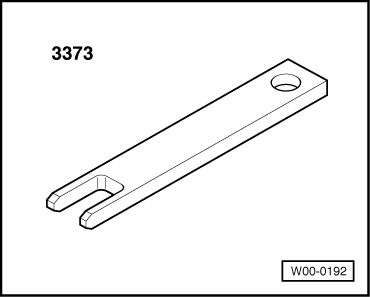

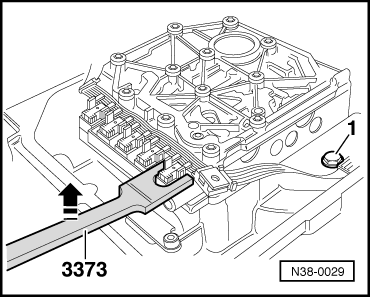

| q | Pulling off solenoid valves with -3373- → Fig.. |

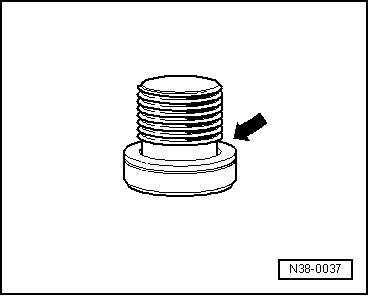

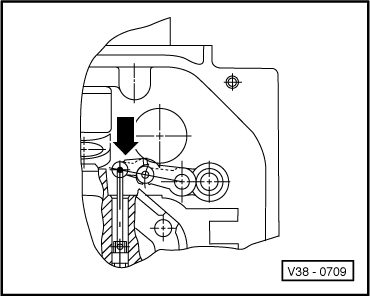

| 15 - | Sealing plug |

| q | Taking out before removing and installing freewheel. |

| q | Inserting so that the lug is located in the groove on housing → Fig.. |

| q | Placing O-rings onto sealing plug. |

| 16 - | O-ring |

| q | Always renewing. |

| 17 - | O-ring |

| q | Always renewing. |

| 18 - | Operating rod for spool valve |

| q | Unhooking → Fig.. |

| q | Installing with stepped side facing spool valve → Fig.. |

| q | Adjusting → Fig.. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warning

Warning