Leon Mk1

| Removing and installing clutch |

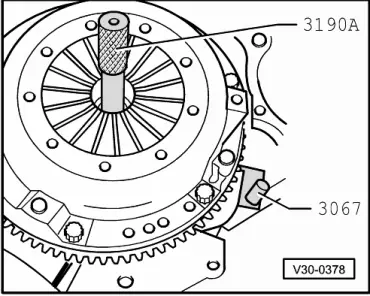

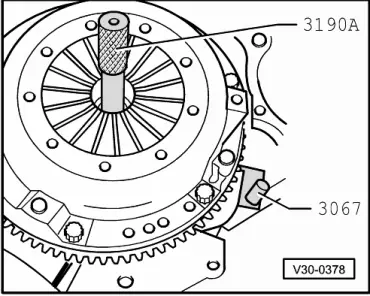

| Special tools and workshop equipment required |

| t | Counterhold tool -3067- |

| t | Centring mandrel. -3190 A- |

| t | Torque wrench -V.A.G 1331- |

| t | Grease for clutch plate splines -G 000 100- |

|

Note

Note

|

|

|

|

|

|

| Removing and installing clutch |

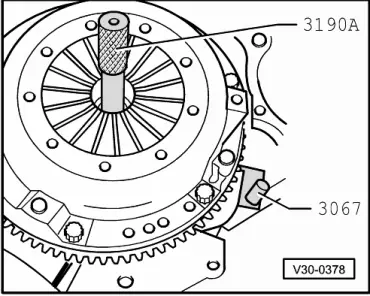

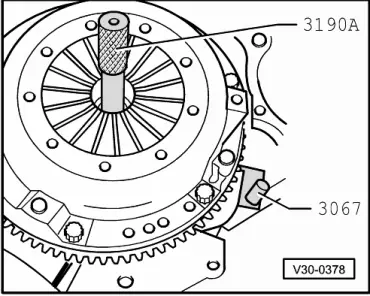

| Special tools and workshop equipment required |

| t | Counterhold tool -3067- |

| t | Centring mandrel. -3190 A- |

| t | Torque wrench -V.A.G 1331- |

| t | Grease for clutch plate splines -G 000 100- |

|

Note

Note

|

|

|

|

|

|