Note | t

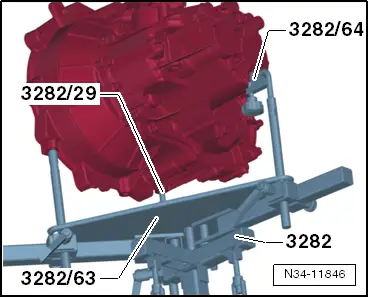

| Refer to procedure „Removing gearbox“ for required special tools → Chapter. |

| t

| Renew self-locking nuts and bolts. |

| t

| Replace bolts that are tightened with specified tightening angle. |

| t

| All cable ties which were opened or cut during removal must be renewed at the same points. |

| t

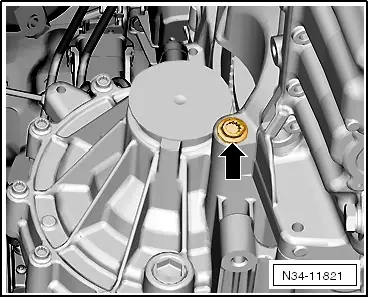

| Clean input shaft splines and, on used clutch plate, hub splines. Remove corrosion and apply only a very thin coat of clutch plate spline grease -G 000 100- to splines. Then move the clutch plate on the input shaft from side to side, until the hub moves smoothly on the shaft. It is important to remove excess grease. |

| –

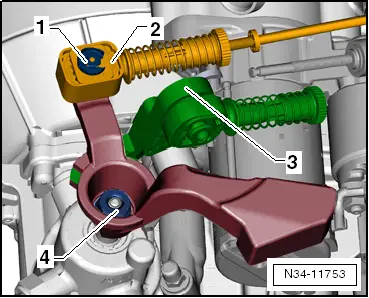

| If the gearbox is to be renewed, the gearbox selector lever and relay lever must be transferred to the new gearbox. |

| –

| Carefully use thread tap to remove any remaining locking fluid from all threaded holes which will accommodate self-locking bolts. |

| –

| Clean splines of input shaft and apply a thin coat of grease for clutch plate splines -G 000 100-. |

| The clutch plate must slide easily to and fro on the input shaft. |

| –

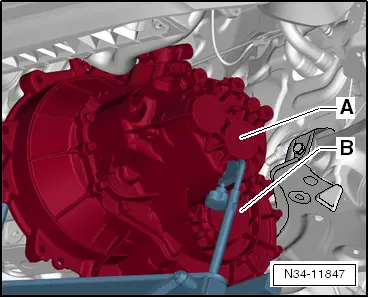

| If no dowel sleeves for aligning engine and gearbox are fitted in cylinder block, install if necessary. |

| If the dowel sleeves are not fitted, this will lead to gear-change problems, clutch malfunction and in some cases gearbox noise (gears will make rattling noises). |

|

|

|

Note

Note

Note

Note

Note

Note

WARNING

WARNING