Leon Mk1

| Removing gearbox |

| Special tools and workshop equipment required |

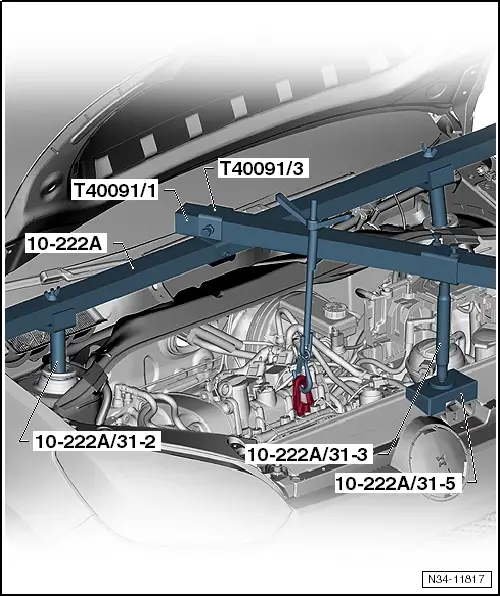

| t | Support bracket -10 - 2 A- |

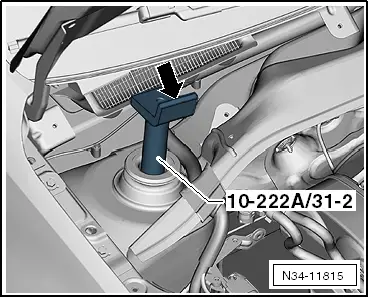

| t | Adapter -10 - 2 A /31-2- |

| t | Support -10 - 2 A /31-3- |

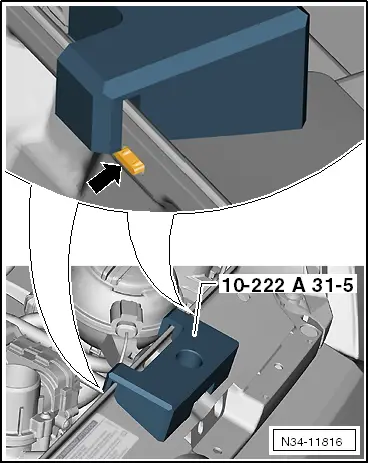

| t | Adapter -10 - 2 A /31-5- |

| t | Square tube -T40091/1- |

| t | Connector -T40091/3- |

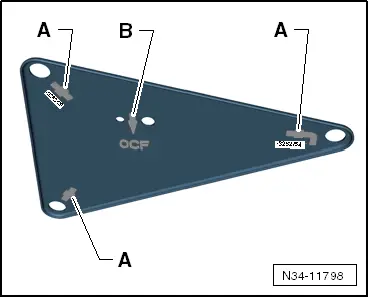

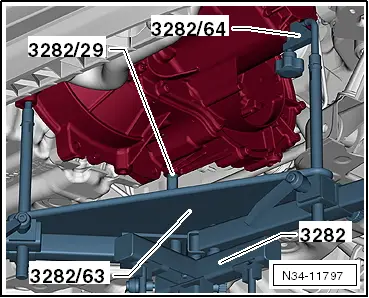

| t | Gearbox support assembly -3282- |

| t | Adjustment plate -3282/63- |

| t | Adapter -3282/64- |

| t | Support elements for gearbox (determine when setting adjustment plate on gearbox support) |

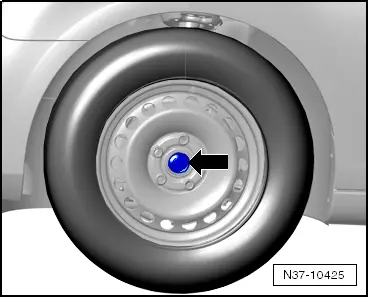

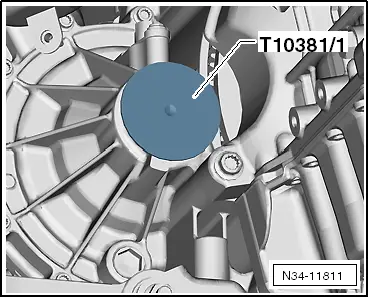

| t | Sealing cap -T10381/1- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Gearbox lifting tackle -3336- for transporting gearbox |

| t | Grease for clutch plate splines -G 000 100- |

| t | Allocate grease using → Electronic parts catalogue (ETKA). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Caution

Caution