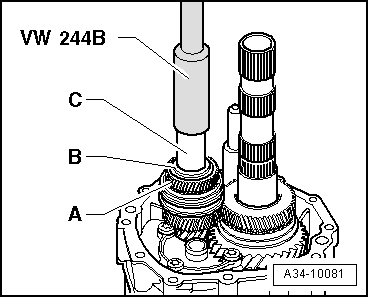

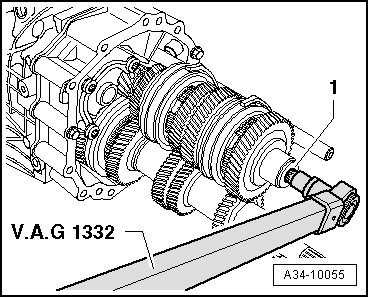

WARNING | If the input shaft or the gearbox housing have been renewed, you must first re-determine the thickness of the input shaft circlips → Chapter. |

|

| t

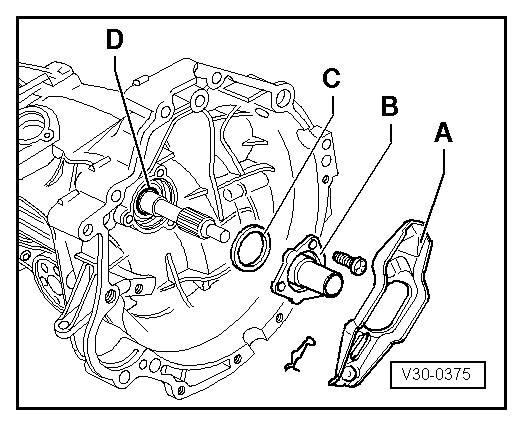

| Assembly overview of the input shaft → Chapter |

| t

| Assembly overview of the secondary shaft → Chapter |

Note | t

| Lubricate all needle bearings with gear oil before fitting. |

| t

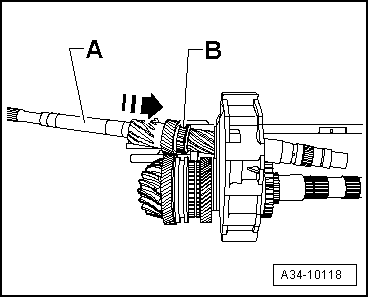

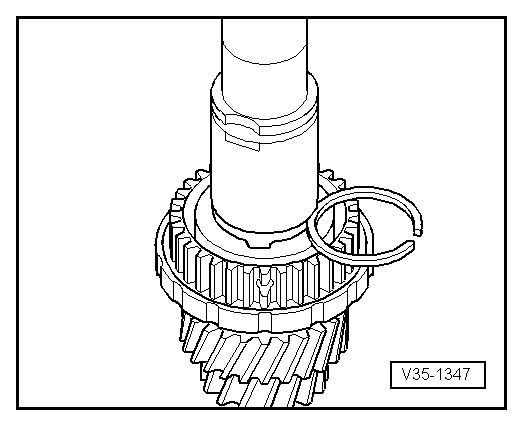

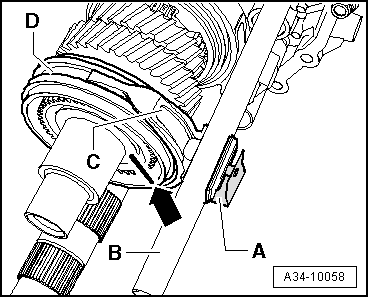

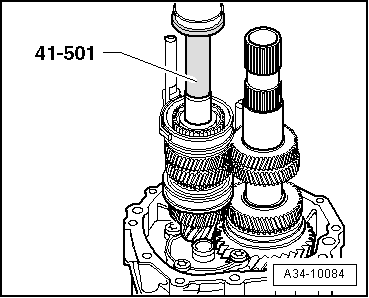

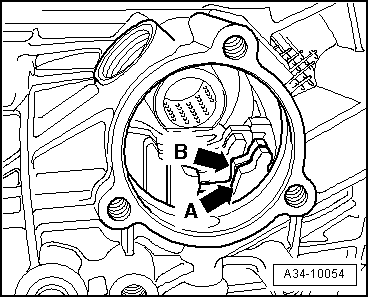

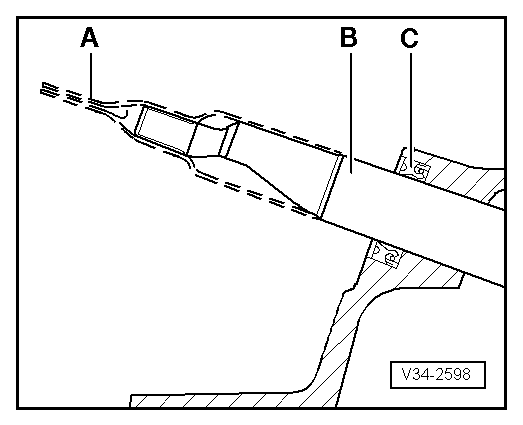

| Check synchro-rings for wear → Fig. |

| t

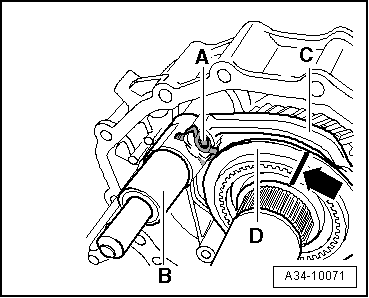

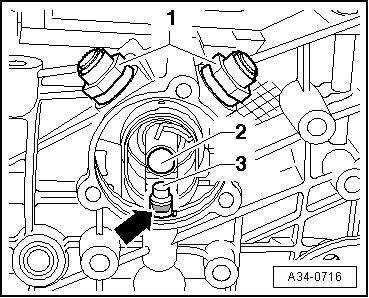

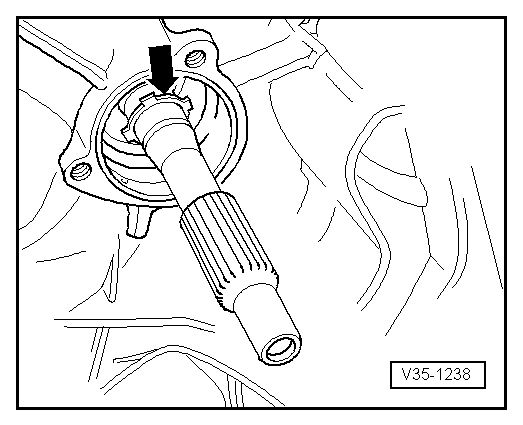

| Insert spring in selector gear → Fig. |

| t

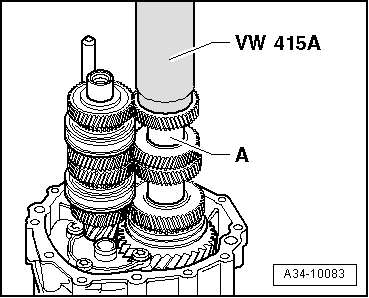

| Heat gear wheels, needle bearing inner races and synchronising hubs to 130 °C (max.) before pressing on (wear protective gloves). |

| –

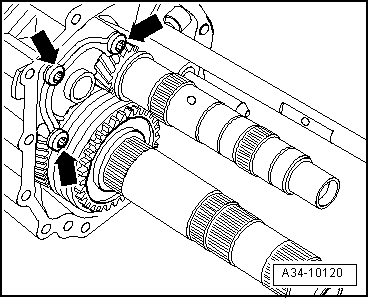

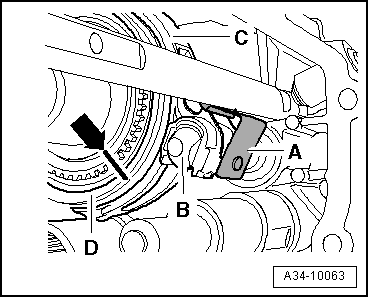

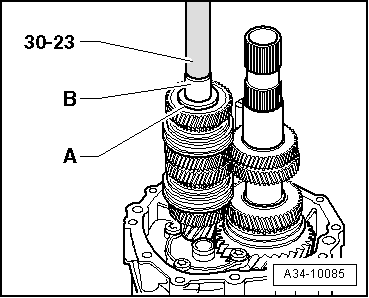

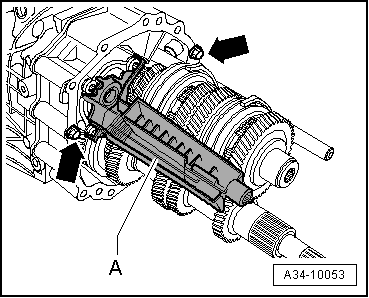

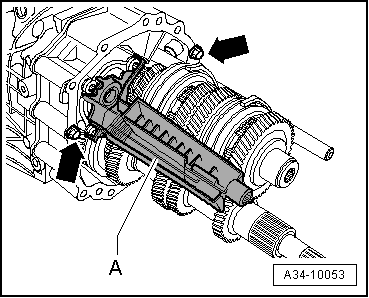

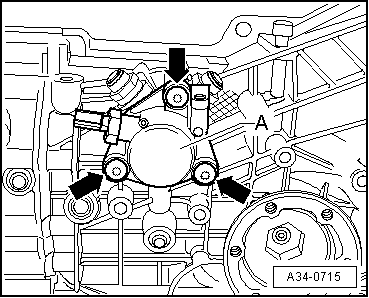

| Insert output shaft in bearing housing and selector fork for 1st and 2nd gear. |

| –

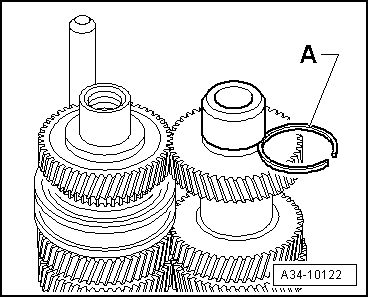

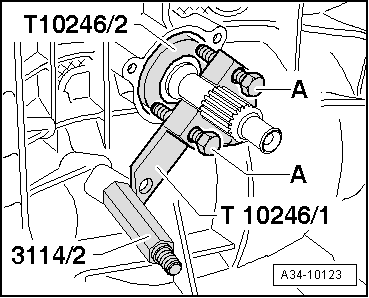

| Place reverse gear selector gear with needle bearing, spring and synchro-ring onto output shaft. |

| l

| The lugs on synchro-ring should engage into recesses in selector gear. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING Caution

Caution