| –

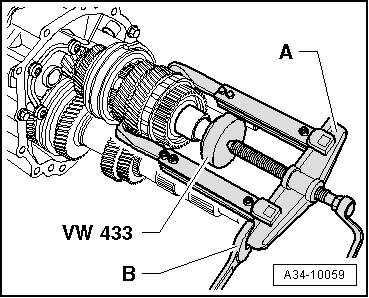

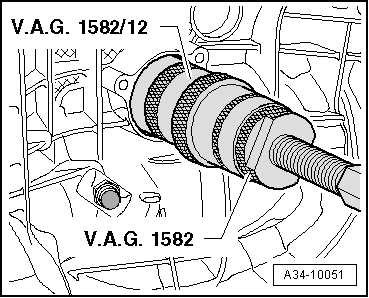

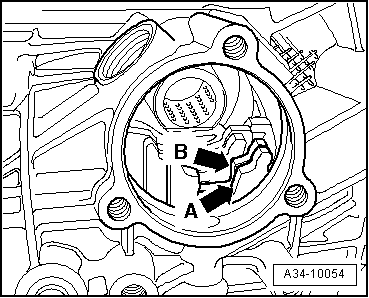

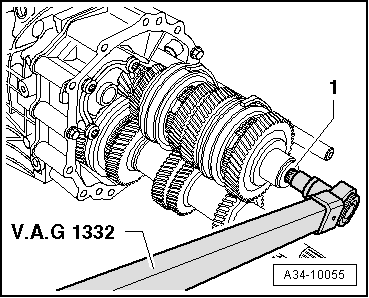

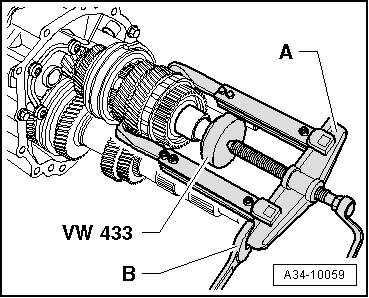

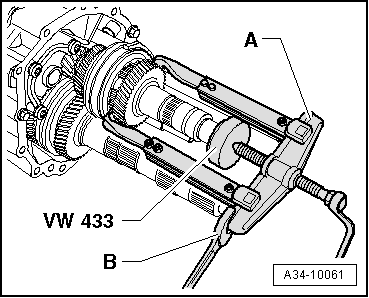

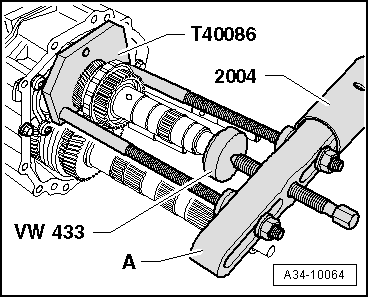

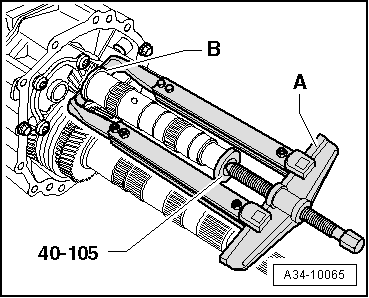

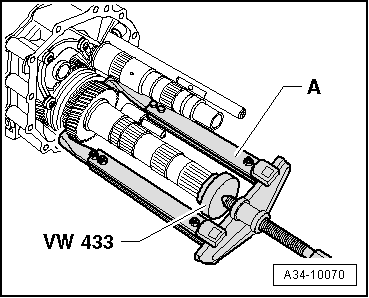

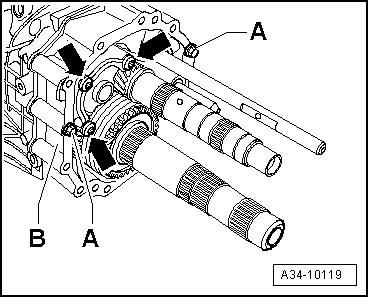

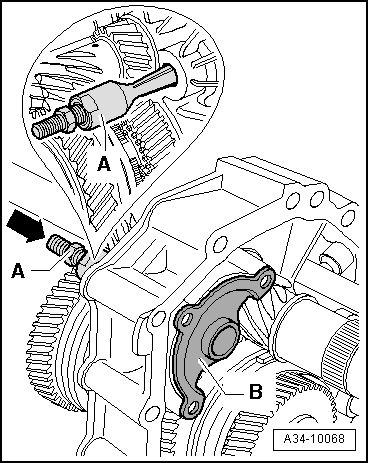

| Pull off 5th speed selector gear together with needle bearing inner race for 6th gear and synchronising hub for 5th and 6th gear. |

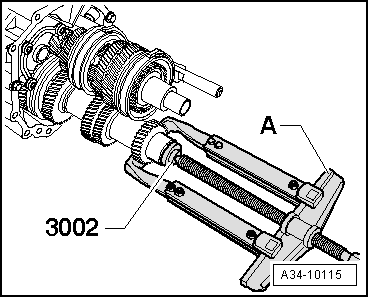

| A - | Two-arm puller, e.g. -Kukko 20/10- with puller hook, length 200 mm |

Note | t

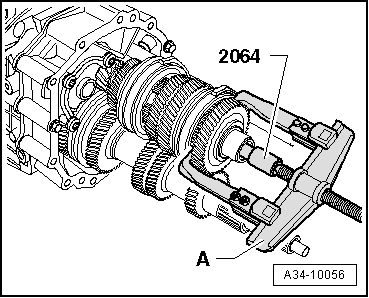

| Counter-hold two-arm puller using e.g. open end spanner -B-. |

| t

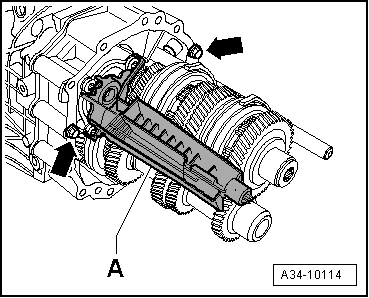

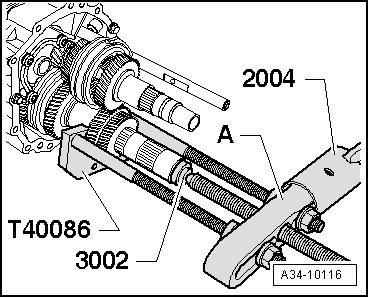

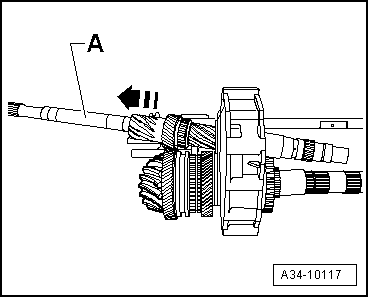

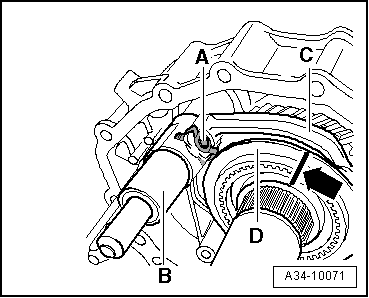

| If the needle bearing inner race for 6th gear is in contact with press tool - VW 433-, insert locking pin -2064- into hole in input shaft to pull off the components all the way. |

| t

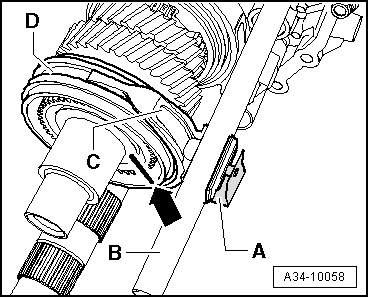

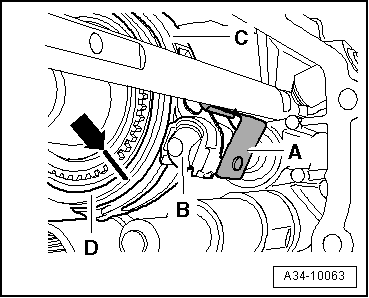

| Never force the extraction of the inside rings / sleeves. If necessary, clean and heat with a maximum temperature of 130°C. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note