| –

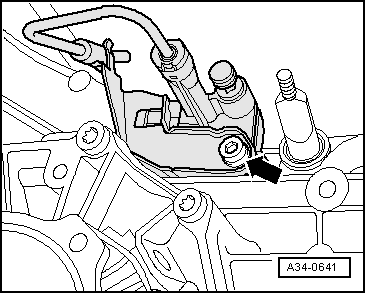

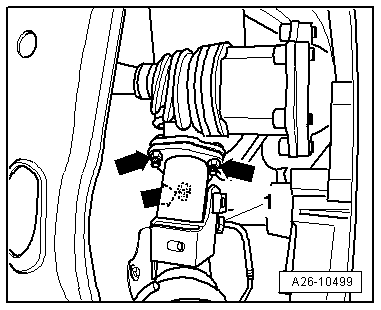

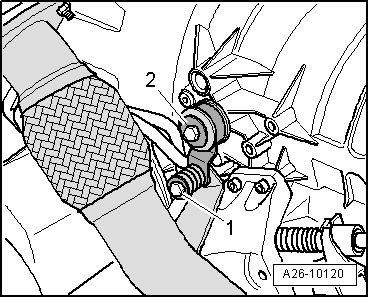

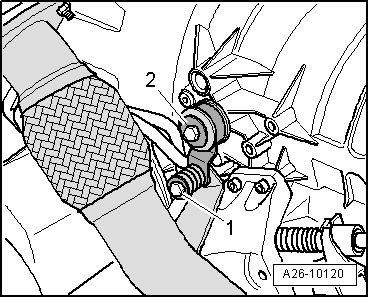

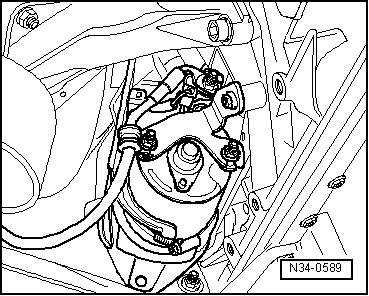

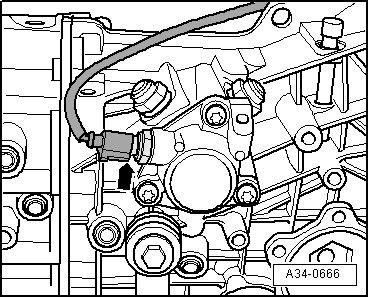

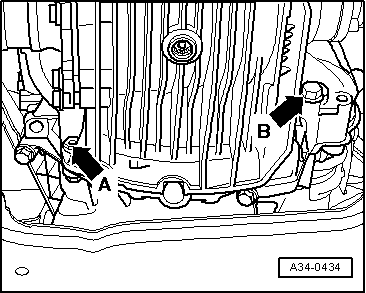

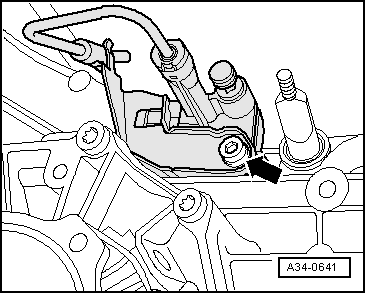

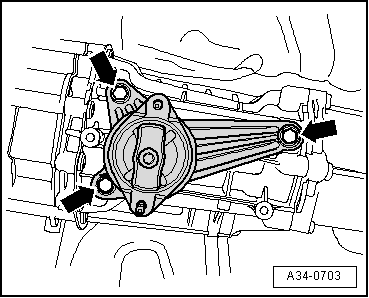

| Detach clutch slave cylinder from gearbox -arrow- and secure with wire; do not open pipe/hose system. |

Caution | Do not press on the clutch pedal following the removal of the slave cylinder. The slave cylinder would then be destroyed once pedal force exceeds approx. 300 N. |

|

| –

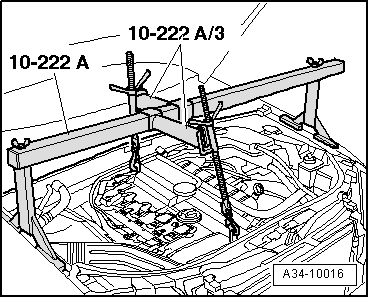

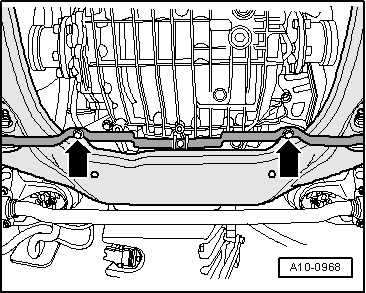

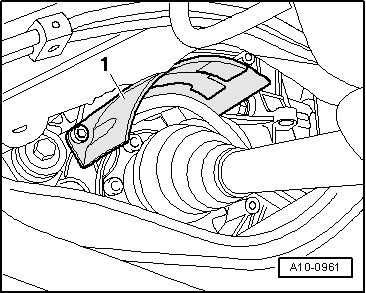

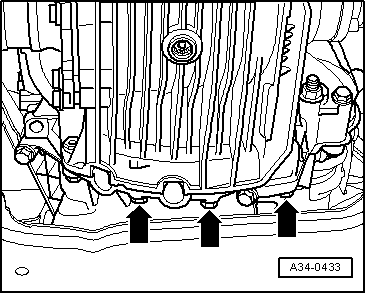

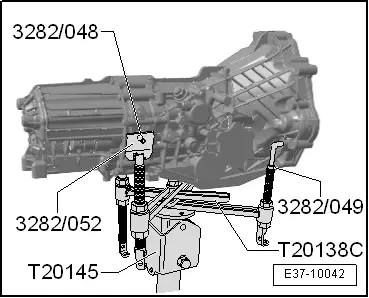

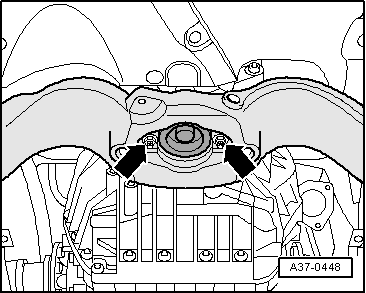

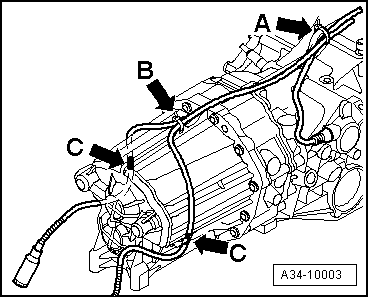

| Completely lower the gearbox using the engine and gearbox jack -SAT 1040-. |

Note | When lowering gearbox, make sure there is sufficient clearance from drive shafts. |

| –

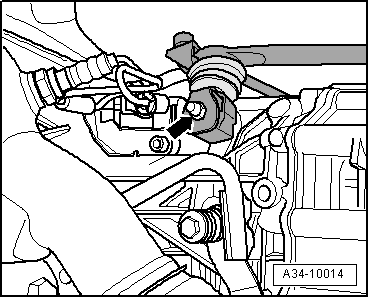

| Before carrying out assembly work, secure gearbox to assembly stand, using engine and gearbox support -VW 540- → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution