Leon Mk1

|

|

|

|

|

|

|

|

|

|

|

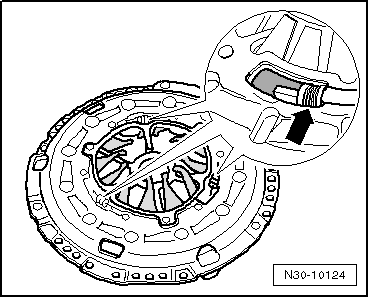

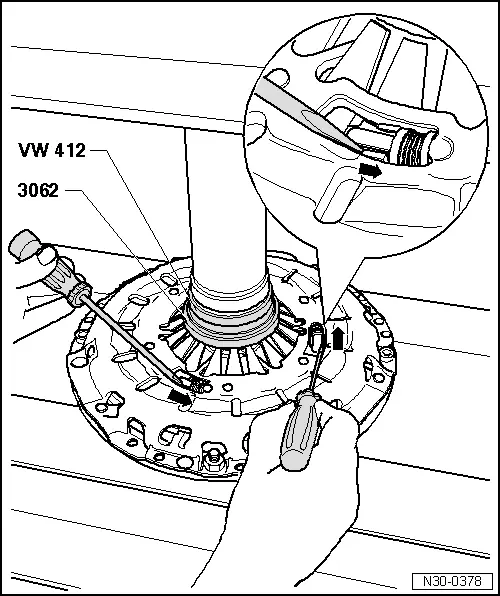

| Do not use excessive force for the following work or the adjuster ring forks may break off. |

| – | Apply two screwdrivers to pins on adjusting ring. |

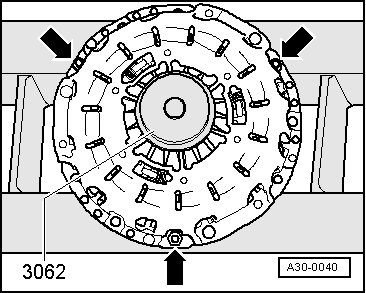

| – | Press down on pressure plate with press until adjusting ring can just be moved. |

| – | Using the two screwdrivers, turn back adjusting ring evenly in direction of arrows to stop. |

| – | Hold adjusting ring against stop and reduce pressure exerted by the press so that adjusting ring is held in this position. |