Leon Mk1

| Repairing clutch housing, from gearbox date 13 01 3 |

| Special tools and workshop equipment required |

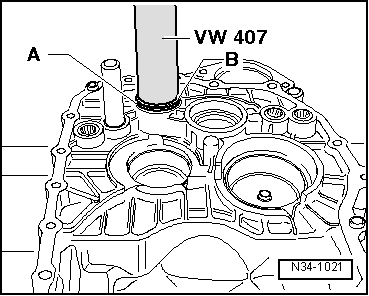

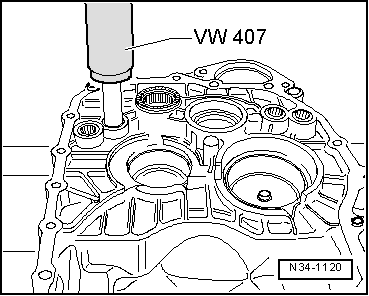

| t | Press tool -VW 407- |

| t | Sleeve -30-21- |

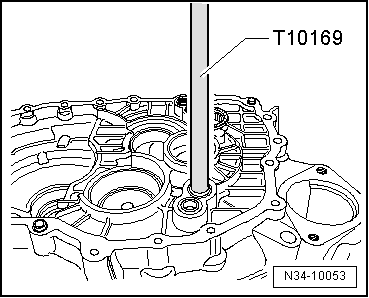

| t | Drift -T10168- |

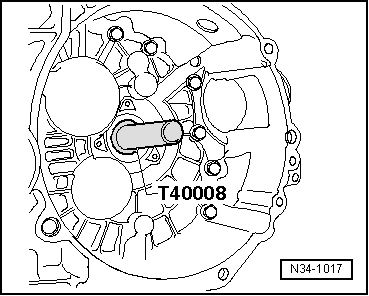

| t | Thrust piece -T40008- |

| t | Thrust piece -VW 431- |

| t | Thrust piece -VW 432- |

| t | Internal puller -1 - Kukko 21/2- |

| t | Internal puller -1 - Kukko 21/4- |

| t | Counter support -4 - Kukko 22/2- |

|

|

|

|

|

|

| 1 - | Bearing bush |

| q | For selector rods |

| q | Renew each time after removing |

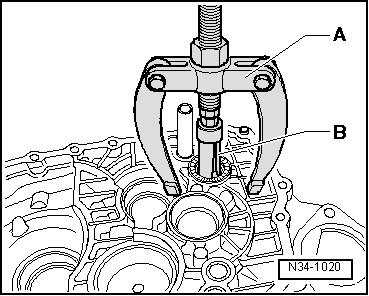

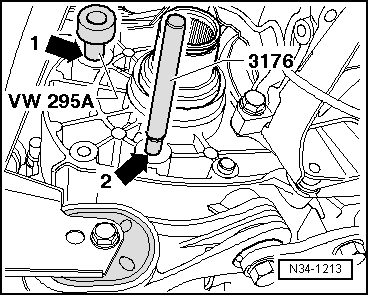

| q | Pulling out → Fig. |

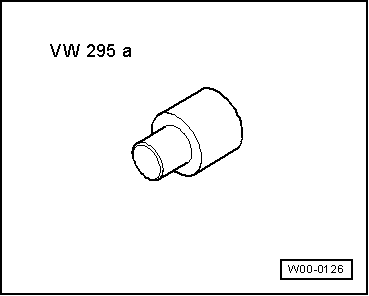

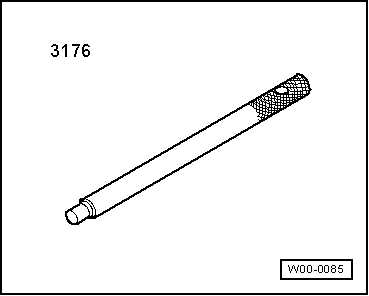

| q | Driving in → Fig. |

| 2 - | Reverse gear selector fork axle |

| q | Axle cannot be removed with workshop tools |

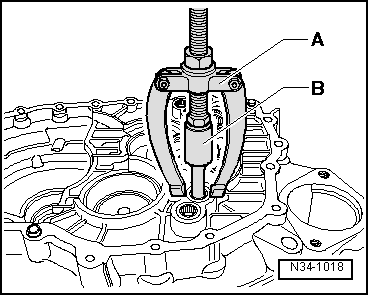

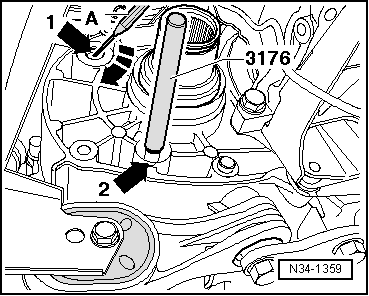

| q | If a new clutch housing is used, a new axle must be pressed in → Fig. |

| 3 - | Needle bearing |

| q | For reverse shaft |

| q | Renew each time after removing |

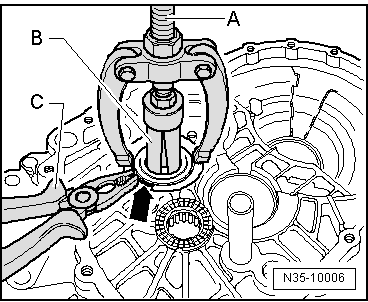

| q | Pulling out → Fig. |

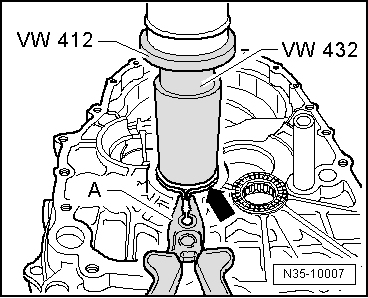

| q | Pressing in → Fig. |

| 4 - | Dowel sleeve |

| q | Qty. 2 |

| 5 - | Clutch housing |

| q | When replacing: → Chapter, Adjustment overview |

| 6 - | Cap |

| q | Not fitted in all clutch housings |

| 7 - | Input shaft seal |

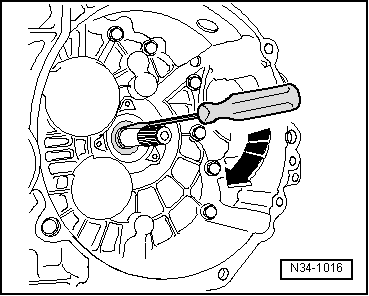

| q | Removing → Fig. |

| q | Installing → Fig. |

| 8 - | Seal |

| q | For right flange shaft |

| q | Renewing with gearbox installed → Chapter |

| 9 - | Small sealing cover |

| q | If it leaks, drive in 20 mm deeper (gearbox installed) → Fig. |

| q | Installing → Fig. |

| 10 - | Large sealing cover |

| q | Removing → Fig. |

| q | Installing → Fig. |

| 11 - | Washer |

| q | For differential |

| q | Installation position: shoulder on inner circumference faces seal → Item |

| 12 - | Tapered roller bearing outer race |

| q | For differential |

| q | Removing and installing → Chapter |

| q | If renewed, adjust differential → Chapter |

| 13 - | Oil deflector ring |

| q | Installation position: shoulder on hole faces output shaft |

| 14 - | Tapered roller bearing outer race |

| q | For output shaft for 1st through 4th gears |

| q | Removing and installing → Fig. |

| q | If renewed, adjust output shaft for 1st through 4th gears → Chapter |

| 15 - | Tapered roller bearing outer race |

| q | For output shaft for 5th, 6th and reverse gears |

| q | Removing and installing → Fig. |

| q | If renewed, adjust output shaft for 5th, 6th and reverse gears → Chapter |

| 16 - | Washer |

| q | For output shaft |

| q | Always 0.65 mm thick |

| 17 - | Cylindrical roller bearing |

| q | For input shaft |

| q | Removing and installing → Fig. |

| 18 - | Magnet |

| q | Held in place by housing joint surface |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note