Leon Mk1

| Repairing gearbox housing, from gearbox date 13 01 3 |

| Special tools and workshop equipment required |

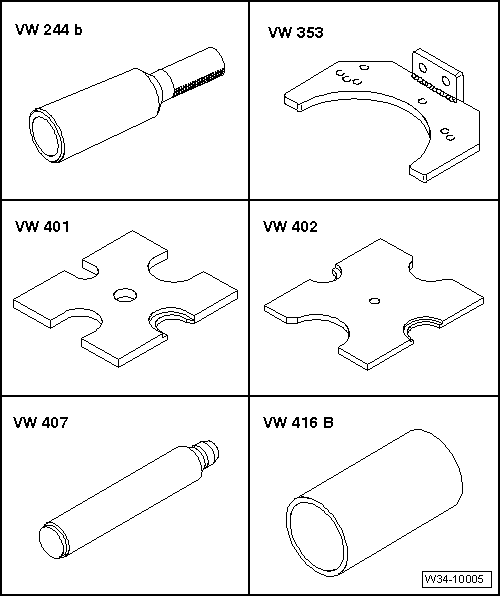

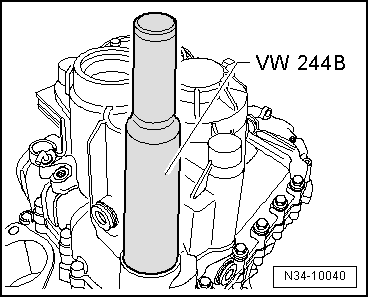

| t | Drift sleeve -VW 244B- |

| t | Gearbox support -VW 353- |

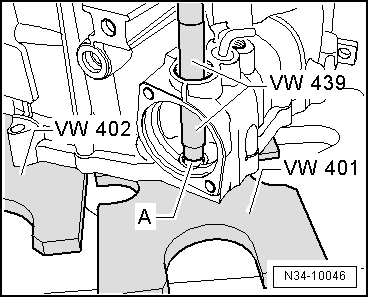

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

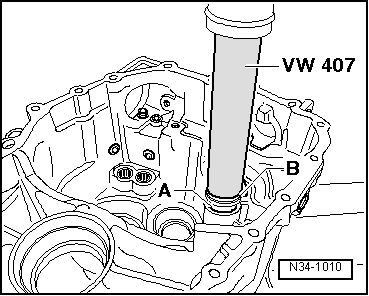

| t | Press tool -VW 407- |

| t | Tube -VW 416 B- |

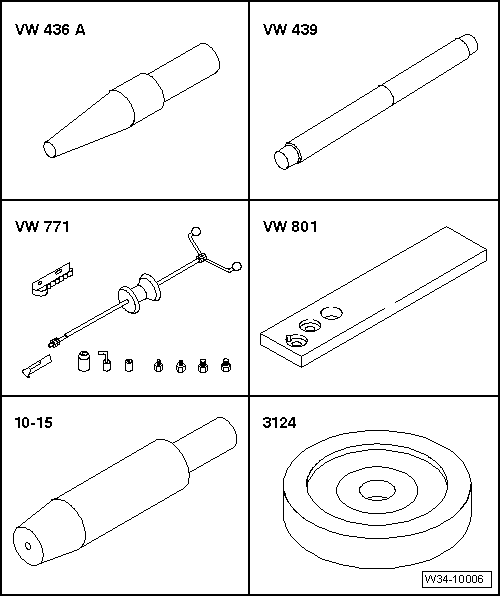

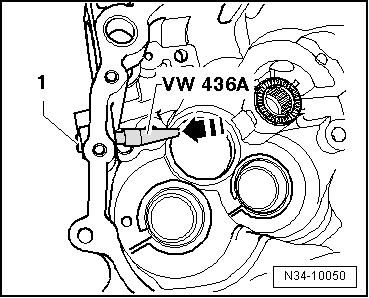

| t | Guide pin -VW 436 A- |

| t | Guide pin -VW 439- |

| t | Multipurpose tool -VW 771- |

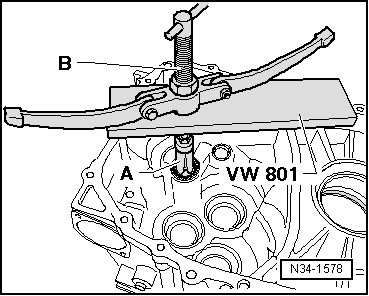

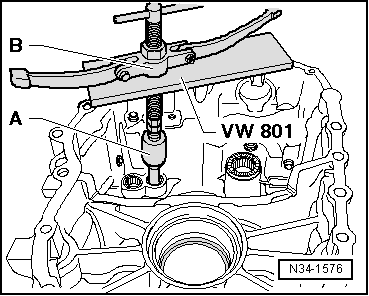

| t | Support plate -VW 801- |

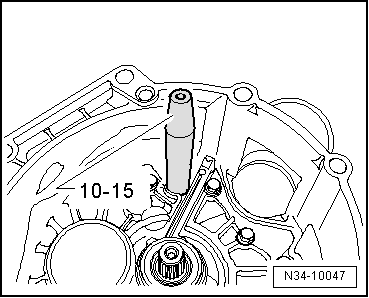

| t | Guide pin -10-15- |

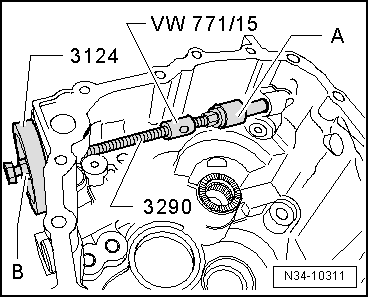

| t | Thrust piece -3124- |

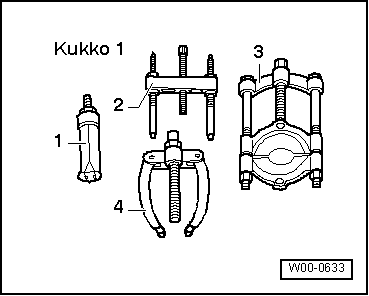

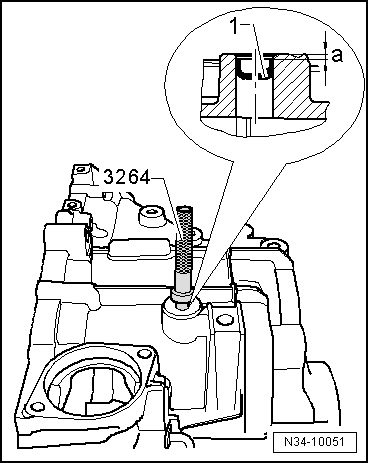

| t | Drift -3264- |

| t | Assembly tool -3290- |

| t | Torque wrench -V.A.G 1331- |

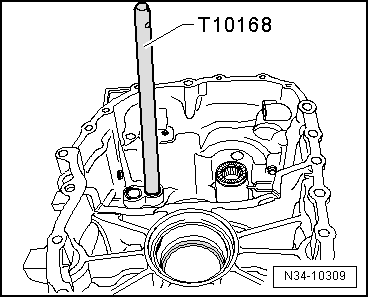

| t | Drift -T10168- |

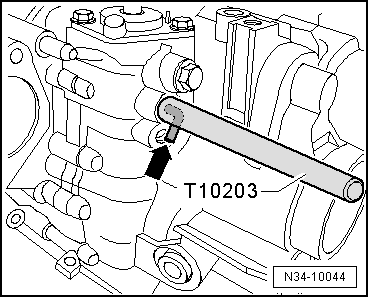

| t | Thrust piece -T10203- |

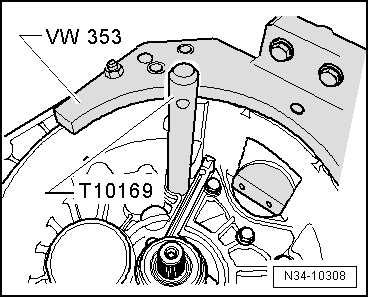

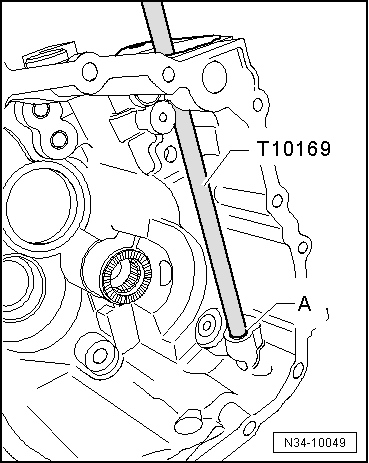

| t | Drift -T10169- |

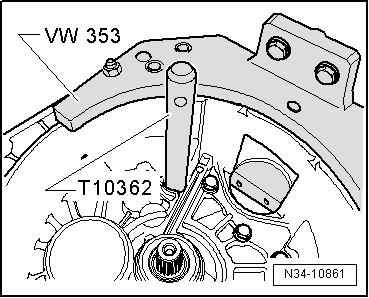

| t | or drift -T10362- → Fig. |

|

|

|

|

| 1 - | Gearbox housing |

| q | If renewed: adjust output shafts and differential → Chapter |

| q | Changes in area of support for deep groove ball bearing for input shaft → Item. |

| q | Allocation of components → Electronic parts catalogue (ETKA) |

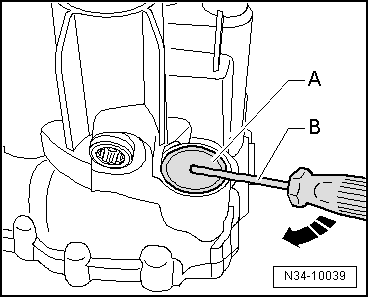

| 2 - | Sealing cover |

| q | Removing → Fig. |

| q | Driving in → Fig. |

| 3 - | Oil drain plug |

| q | Torque setting → Fig. |

| 4 - | Seal |

| q | Always renew, if part of original equipment |

| 5 - | Oil filler plug |

| q | Torque setting → Fig. |

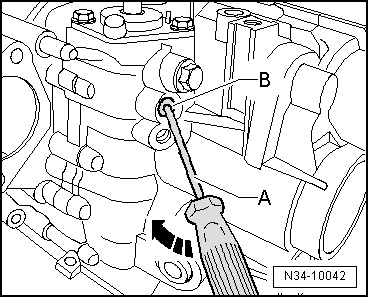

| 6 - | Angled rod |

| q | For adjusting selector mechanism → Chapter |

| q | Can be renewed with gearbox assembled |

| q | Removing → Fig. |

| q | Installation position → Fig. |

| q | Driving in → Fig. |

| 7 - | Bearing bush |

| q | For selector rods |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

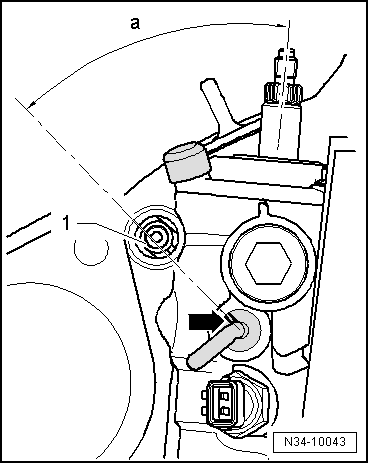

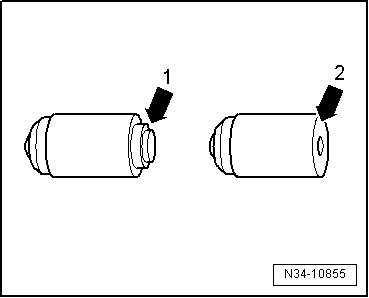

| 8 - | Stop sleeve |

| q | Pressing out with gearbox dismantled → Fig. |

| q | Pressing out with gearbox assembled → Fig. |

| q | Stop sleeve identification → Fig. |

| q | Drive in stop sleeve with shoulder → Fig. |

| q | Drive in stop sleeve without shoulder → Fig. |

| 9 - | Needle bearing |

| q | For reverse shaft |

| q | Renew each time after removing |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 10 - | Tapered roller bearing outer race |

| q | For output shaft for 5th, 6th and reverse gears |

| q | Removing and installing → Fig. |

| q | If renewed, adjust output shaft for 5th, 6th and reverse gears → Chapter |

| 11 - | Shim |

| q | For output shaft for 5th, 6th and reverse gears |

| q | Adjustment overview → Chapter |

| 12 - | Tapered roller bearing outer race |

| q | For output shaft for 1st through 4th gears |

| q | Removing and installing → Chapter |

| q | If renewed, adjust output shaft for 1st through 4th gears → Chapter |

| 13 - | Shim |

| q | For output shaft for 1st through 4th gears |

| q | Adjustment overview → Chapter |

| 14 - | Tapered roller bearing inner race |

| q | For differential |

| q | Removing and installing → Chapter |

| q | If renewed, adjust differential → Chapter |

| 15 - | Shim |

| q | For differential |

| q | Adjustment overview → Chapter |

| 16 - | Bearing bush |

| q | For selector shaft |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

| 17 - | Plug |

| q | Driving out → Fig. |

| q | Driving in → Fig. |

| 18 - | Seal |

| q | Renewing → Chapter |

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|