| –

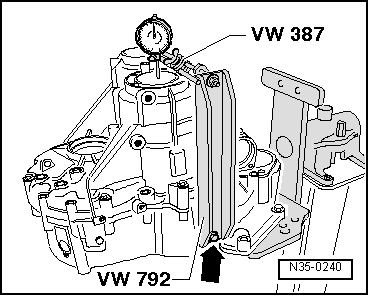

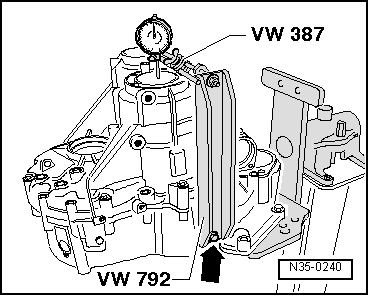

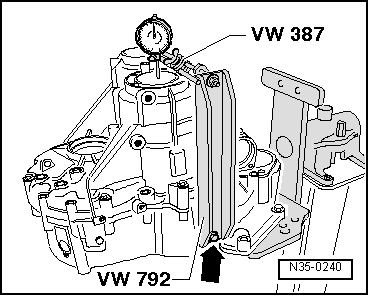

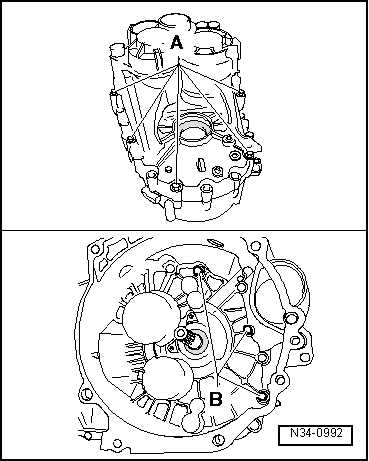

| Set up measuring tools and secure to clutch housing using bolt -arrow-. |

| –

| Set dial gauge (3 mm measuring range) to “0” with 1 mm preload. |

| –

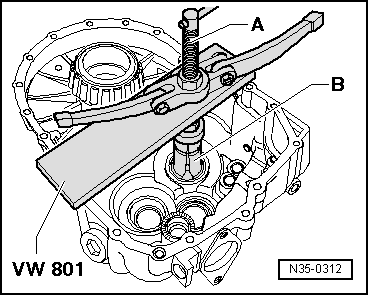

| Loosen clutch housing/gearbox housing securing bolts diagonally until output shaft or gearbox housing is free. |

| –

| Read and note value on dial gauge (example: 0.14 mm). |

Note | t

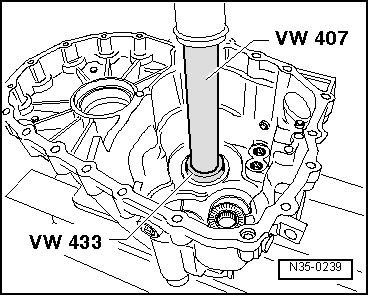

| If dial gauge indicates no value when clutch housing/gearbox housing securing bolts are loosened, install 1.95 mm shim or, if necessary, 2.20 mm shim when taking measurements. |

| Determining thickness of shim |

| The specified bearing preload will be attained by subtracting the measured value (0.14 mm) from the inserted shim (1.70 mm) and adding a constant value for preload (0.20 mm). |

|

|

|

Note

Note