Leon Mk1

| Adjusting input shaft, through gearbox date 12 01 3 |

| (Determining input shaft shim) |

Note

Note| t | The adjusting instructions apply only to gearboxes through gearbox date 12 01 3 (input shaft supported with tapered roller bearings). |

| t | From gearbox date 13 01 3, the input shaft support has been modified → Chapter. Adjustment is no longer required. |

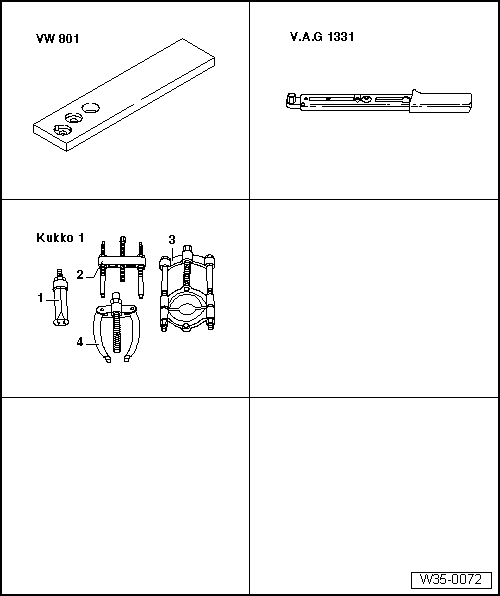

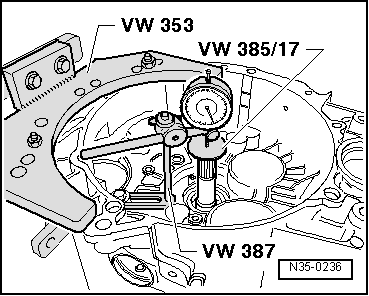

| Special tools and workshop equipment required |

| t | Support plate -VW 309- |

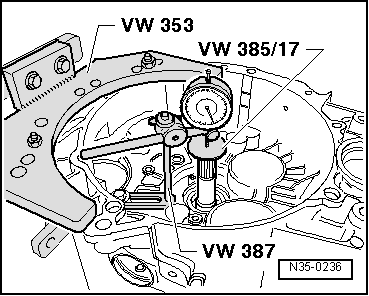

| t | Gearbox support -VW 353- |

| t | End dimension plate -VW 385/17- |

| t | Universal dial gauge bracket -VW 387- |

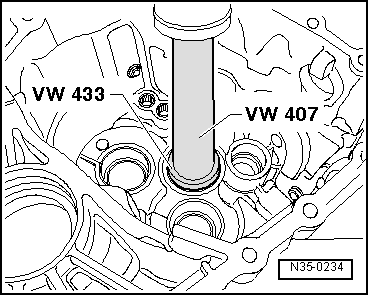

| t | Press tool -VW 407- |

| t | Thrust piece -VW 433- |

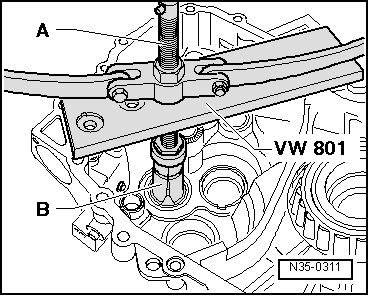

| t | Support plate -VW 801- |

| t | Torque wrench -V.A.G 1331- |

| t | Internal puller -1- Kukko 21/7- |

| t | Counter support -4- Kukko 22/1- |

|

|

|

Note

Note

|

|

|

|

| Bearing play | Shim |

| Measured value (mm) | Thickness (mm) |

| 1.480 ... 1.524 | 1.40 |

| 1.525 ... 1.574 | 1.45 |

| 1.575 ... 1.624 | 1.50 |

| 1.625 ... 1.674 | 1.55 |

| 1.675 ... 1.724 | 1.60 |

| 1.725 ... 1.774 | 1.65 |

| 1.775 ... 1.824 | 1.70 |

| 1.825 ... 1.874 | 1.75 |

| 1.875 ... 1.924 | 1.80 |

| 1.925 ... 1.974 | 1.85 |

| 1.975 ... 2.024 | 1.90 |

| 2.025 ... 2.074 | 1.95 |

| 2.075 ... 2.124 | 2.00 |

| Bearing play | Shim |

| Measured value (mm) | Thickness (mm) |

| 2.125 ... 2.174 | 2.05 |

| 2.175 ... 2.224 | 2.10 |

| 2.225 ... 2.274 | 2.15 |

| 2.275 ... 2.324 | 2.20 |

| 2.325 ... 2.374 | 2.25 |

|

|

|