Leon Mk1

|

|

|

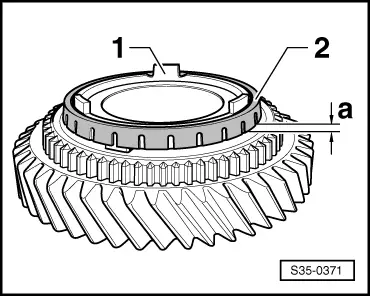

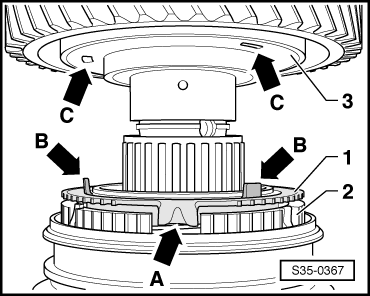

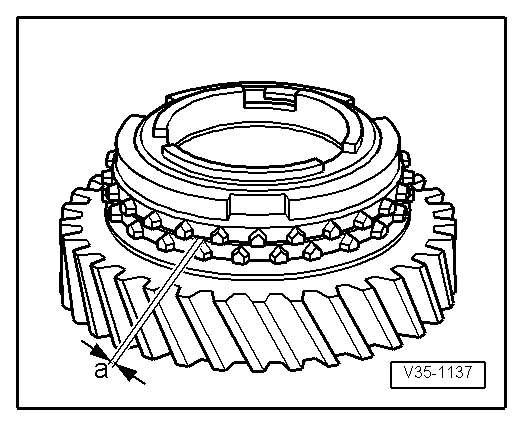

| Gap -a- | Installation (new) dimension | Wear limit |

| 1st and 2nd gears | 1.00 … 1.80 mm | 0.3 mm |

|

|

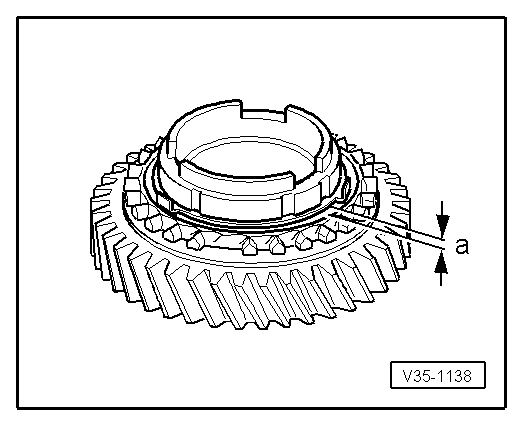

| Gap -a- | Installation (new) dimension | Wear limit |

| 1st and 2nd gears | 1.00 … 1.80 mm | 0.8 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

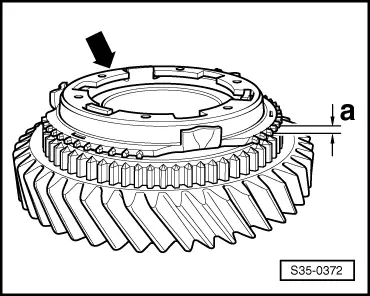

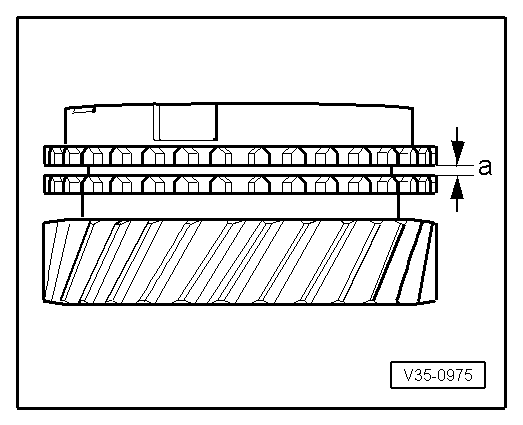

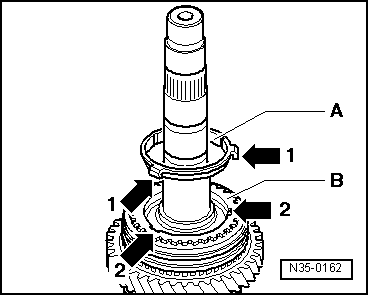

| Gap -a- | Installation (new) dimension | Wear limit |

| 4th gear | 1.0 … 1.7 mm | 0.5 mm |

|

|

|

|

|

|

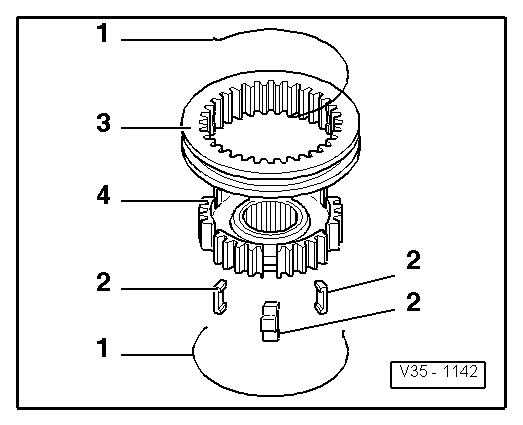

| Gap -a- | Installation (new) dimension | Wear limit |

| 3rd gear | 0.75 … 1.25 mm | 0.3 mm |

|

|

| Gap -a- | Installation (new) dimension | Wear limit |

| 3rd gear | 1.2 … 1.8 mm | 0.5 mm |

|

|

|

|

|

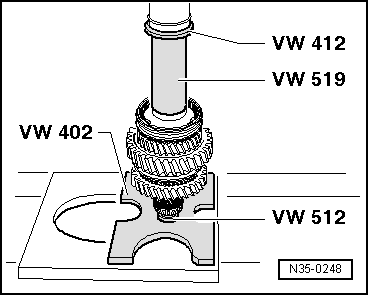

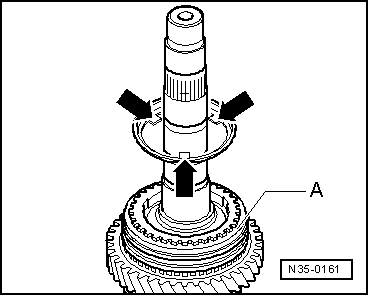

Note

Note

|

|