Leon Mk1

|

| Special tools and workshop equipment required |

| t | Torque wrench kit -SAT 8010-, see equivalent → Anchor |

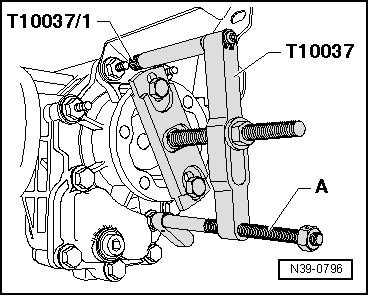

| t | Extractor -T10037-, see equivalent → Anchor |

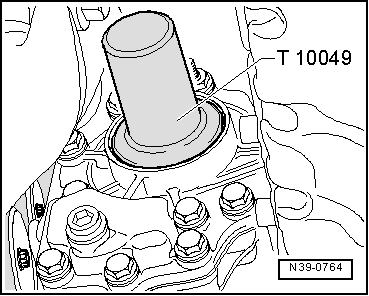

| t | Tappet -T10049-, see equivalent → Anchor |

| t | Tray -T20173-, see equivalent → Anchor |

| t | "1/4" threading die mount" -T20203A-, see equivalent → Anchor |

|

|

|

|

|

Note

Note

|

|

|

|

|

|