Leon Mk1

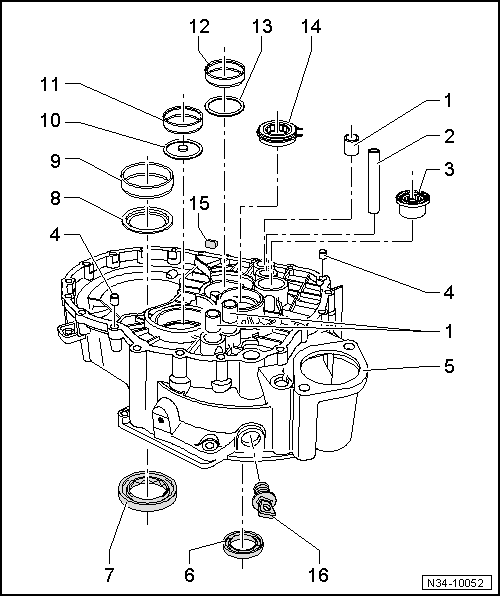

| Clutch housing: general fitting diagram |

| 1 - | Bearing sleeve for the control rods |

| q | Remove → Fig. |

| q | Insert → Fig. |

| 2 - | Reverse gear prong shaft |

| q | This cannot be removed using the workshop tools |

| q | Fit into the clutch housing → Fig. |

| 3 - | Point crown for the inverter shaft |

| q | Replace after each removal |

| q | Remove → Fig. |

| q | Insert → Fig. |

| 4 - | Dowel sleeves |

| q | 2 units |

| 5 - | Clutch housing |

| q | If this is replaced then the secondary differential shafts must be adjusted → Chapter |

| 6 - | Input shaft oil seal |

| q | Replacement → Chapter |

| 7 - | Insert shaft seal |

| q | Replace |

| 8 - | Packing plate |

| q | For the differential |

| q | Fitting position: the interior recesses should point towards the seal → Item |

| 9 - | Outer ring of roller bearing |

| q | For the differential |

| q | Removing and fitting → Fig. |

| q | If replaced the differential must be adjusted → Chapter |

| 10 - | Oil relay washer |

| q | Fitting position: the recess of the hole should face towards the secondary shaft |

| 11 - | Outer ring of roller bearing |

| q | For secondary shaft for 1stª to 4thª gear |

| q | Removing and installing → Fig. |

| q | If replaced, the secondary shaft for 1stª/4thª gear must be readjusted → Chapter |

| 12 - | Outer ring of roller bearing |

| q | For secondary shaft for 5thª/6thª and reverse gear |

| q | Removing and installing → Fig. |

| q | If replaced, the secondary shaft for 5thª/6thª and reverse gear must be readjusted → Chapter |

| 13 - | Packing plate |

| q | For secondary shaft for 5thª/6thª and reverse gear |

| q | 0.65 mm in thickness |

| 14 - | Cylindrical roller bearing |

| q | For the input shaft |

| q | Removing and fitting → Fig. |

| 15 - | Magnet |

| q | Supported by the separation surface of the housing |

| 16 - | Cowling |

| Check the tool and equipment equivalence table according to the applicability between Seat / VW / Audi / Skoda → Chapter. |

| Special tools and workshop equipment required |

| t | Pressure tool -T20129-, see equivalent → Anchor |

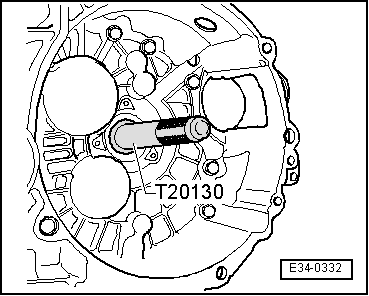

| t | Push rod -T20130-, see equivalent → Anchor |

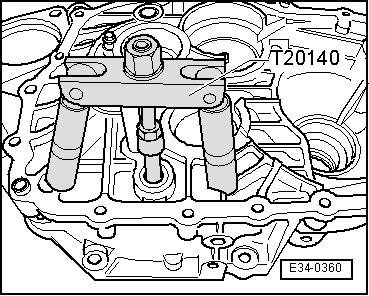

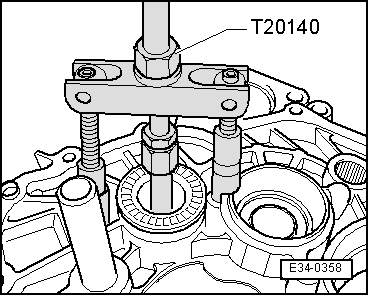

| t | Extractor kit -T20140-, see equivalent → Anchor |

| t | Extractor kit -T20143-, see equivalent → Anchor |

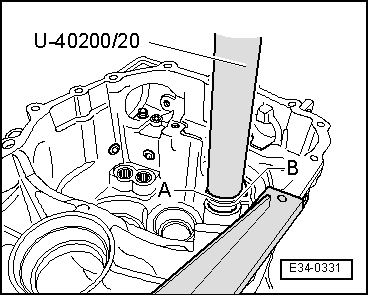

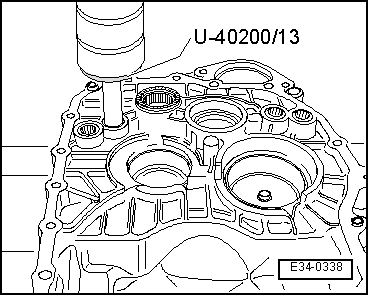

| t | Kit (case) -U-40200A-, see equivalent → Anchor |

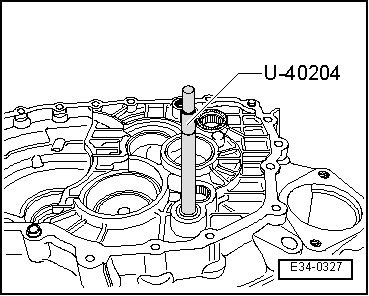

| t | Push rod -U-40204-, see equivalent → Anchor |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|