Leon Mk1

Note

Note

|

| 1 - | Gearbox casing |

| q | If this is replaced then the secondary differential shafts must be adjusted → Chapter |

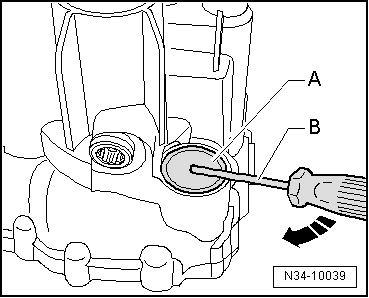

| 2 - | Cover |

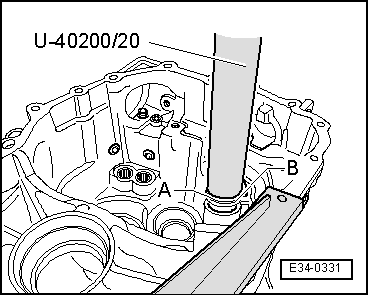

| q | Removing → Fig. |

| q | Insert → Fig. |

| 3 - | Oil empty plug |

| q | Allen screw, -30 Nm |

| 4 - | Seal |

| q | Replacement |

| 5 - | Oil filler plug |

| q | Allen screw, -30 Nm |

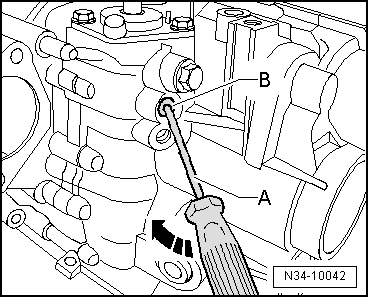

| 6 - | Locking bolt |

| q | To adjust gear selector mechanism → Chapter |

| q | This may be replaced with the gearbox without disassembling |

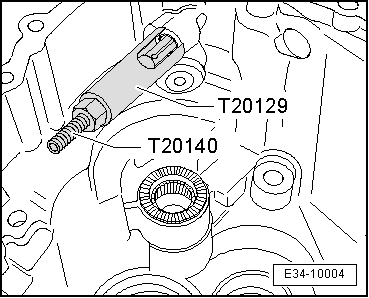

| q | Removing → Fig. |

| q | Installation position → Fig. |

| q | Insert → Fig. |

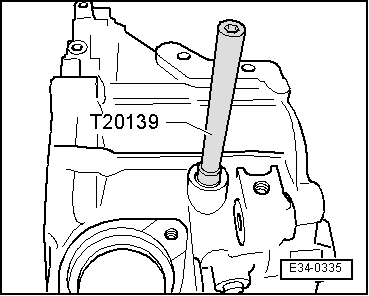

| 7 - | Bearing sleeve for the control rods |

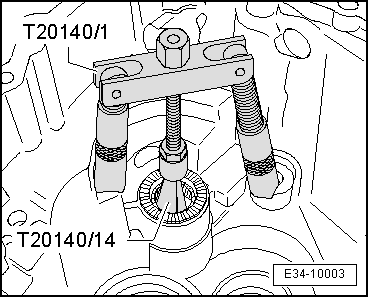

| q | Remove → Fig. |

| q | Insert → Fig. |

| 8 - | Insertion sleeve |

| q | Remove with the gearbox disassembled |

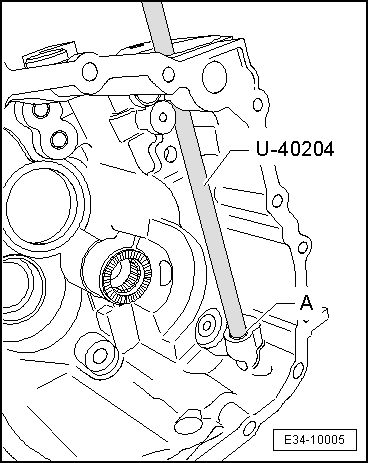

| q | Insert → Fig. |

| 9 - | Point crown for the inverter shaft |

| q | Replace after removing |

| q | Remove → Fig. |

| q | Insert → Fig. |

| 10 - | Outer ring of roller bearing |

| q | For secondary shaft for 5thª/6thª and reverse gear |

| q | Removing and installing → Fig. |

| q | If replaced, the secondary shaft for 5thª/6thª and reverse gear must be readjusted → Chapter |

| 11 - | Shim |

| q | For secondary shaft for 5thª/6thª and reverse gear |

| q | Adjustment chart → Chapter |

| 12 - | Outer ring of roller bearing |

| q | For secondary shaft for 1stª to 4thª gear |

| q | Removing and installing → Chapter |

| q | If replaced, the secondary shaft for 1stª/4thª gear must be readjusted → Chapter |

| 13 - | Shim |

| q | For secondary shaft for 1stª to 4thª gear |

| q | Adjustment chart → Chapter |

| 14 - | Outer ring of roller bearing |

| q | For the differential |

| q | Removing and fitting → Chapter |

| q | If replaced the differential must be adjusted → Chapter |

| 15 - | Shim |

| q | For the differential |

| q | Adjustment chart → Chapter |

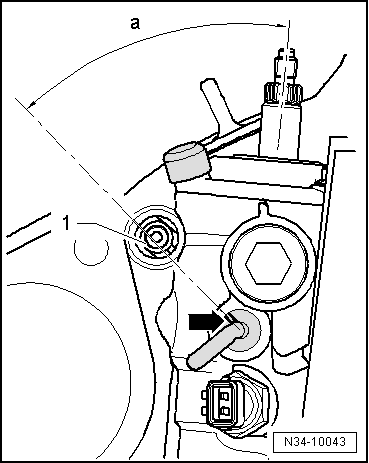

| 16 - | Bearing socket for operation mechanism shaft |

| q | Remove |

| q | Insertion |

| 17 - | Plug |

| q | Releasing |

| q | Insertion |

| 18 - | Seal |

| q | Replacement |

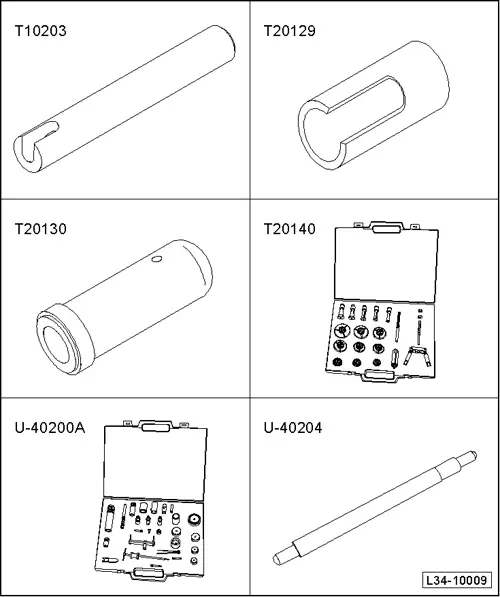

| Check the tool and equipment equivalence table according to the applicability between Seat / VW / Audi / Skoda → Chapter. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|