Leon Mk1

|

| Special tools and workshop equipment required |

| t | Socket wrench e/c 22 -T20202A-, see equivalent → Anchor |

| t | Socket wrench e/c 17 -T20211-, see equivalent → Anchor |

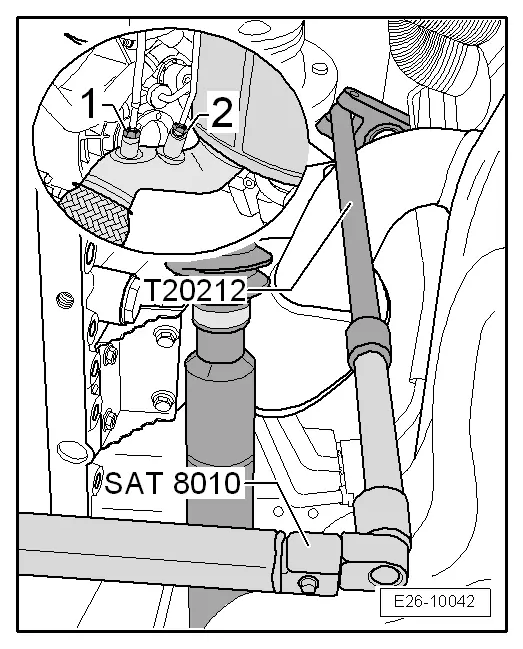

| t | Articulated wrench e/c 17 -T20212-, see equivalent → Anchor |

| t | "Ratchet 1/2"" x 9-12" -VAG 1331/1-, see equivalent → Anchor |

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|