Leon Mk1

| Clutch housing - assembly overview |

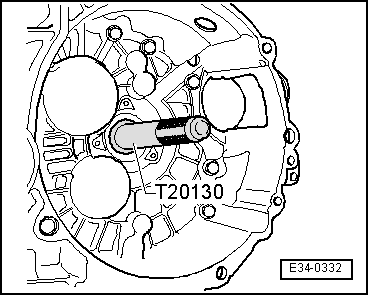

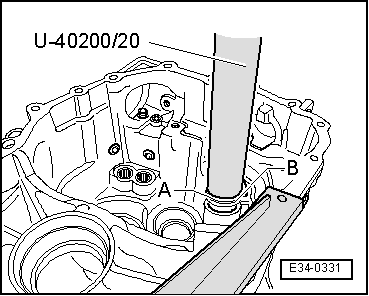

| 1 - | Bearing sleeve for the control rods |

| q | Remove → Fig. |

| q | Driving in → Fig. |

| 2 - | Reverse gear selector fork axle |

| q | Fit the reverse gear prong to the shaft → Fig. |

| q | Axle cannot be removed with workshop tools |

| q | Fit into the clutch housing → Fig. |

| q | When the shaft is not required on the gear selection shaft, fitted on the gear fork of the 5th / 6th gear → Fig.. |

| q | Assign the component according to the → Spare parts catalogue |

| 3 - | Point crown for the inverter shaft |

| q | Always renew if removed |

| q | Remove → Fig. |

| q | Driving in → Fig. |

| 4 - | Dowel sleeve |

| q | 2 off |

| 5 - | clutch housing |

| q | If this is replaced then the secondary differential shafts must be adjusted → Chapter |

| 6 - | Join ring for the input shaft |

| q | Replace → Chapter |

| 7 - | Insert shaft oil seal |

| q | Replace → Chapter |

| 8 - | Plate |

| q | For the differential |

| q | Fitting position: the interior diameter rebate should point towards the seal → Item |

| 9 - | Outer ring of roller bearing |

| q | For the differential |

| q | removing and fitting → Fig. |

| q | If replaced the differential must be replaced → Chapter |

| 10 - | Oil relay washer |

| q | Fitting position: the recess of the hole should face towards the secondary shaft |

| 11 - | Outer ring of roller bearing |

| q | for the secondary shaft for 1st to 4th gear |

| q | removing and fitting → Fig. |

| q | When replacing, the input shaft for 1st to 4th gear must be adjusted → Chapter |

| 12 - | Outer ring of roller bearing |

| q | For 5th/6th and reverse gear output shaft |

| q | removing and fitting → Fig. |

| q | When replacing, the input shaft for 5th / 6th and reverse gear must be adjusted → Chapter |

| 13 - | Plate |

| q | For 5th/6th and reverse gear output shaft |

| q | 0.65 mm thick |

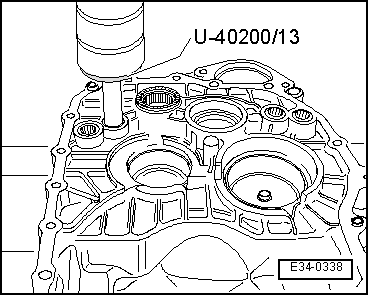

| 14 - | Cylindrical roller bearing |

| q | For input shaft |

| q | removing and fitting → Fig. |

| 15 - | Magnet |

| q | Supported by the separation surface of the housing |

| 16 - | Cap |

| Consult the equivalence table for tools and equipment according to applicability among Seat / VW / Audi / Skoda → Chapter. |

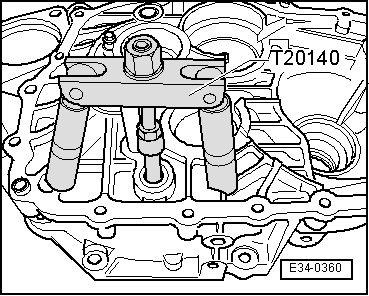

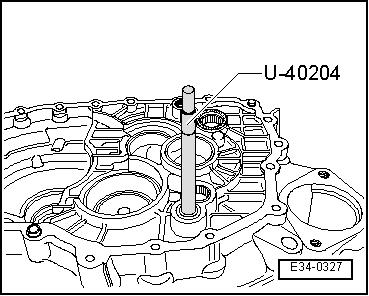

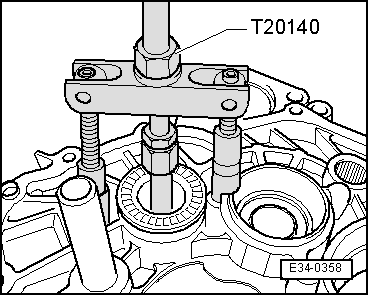

| Special tools and workshop equipment required |

| t | Hose clamp -T20129 -, see equivalent → Anchor |

| t | Tappet -T20130 -, see equivalent → Anchor |

| t | Extractor kit -T20140 -, see equivalent → Anchor |

| t | Extractor kit -T20143 -, see equivalent → Anchor |

| t | Kit (case) -U-40200A -, see equivalent → Anchor |

| t | Tappet -U-40204 -, see equivalent → Anchor |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|