Leon Mk1

|

| Consult the equivalence table for tools and equipment according to applicability among Seat / VW / Audi / Skoda → Chapter. |

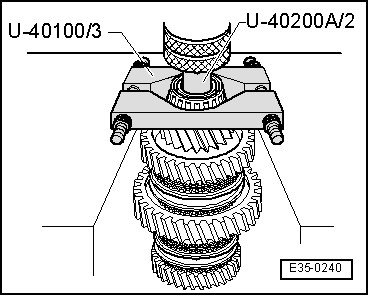

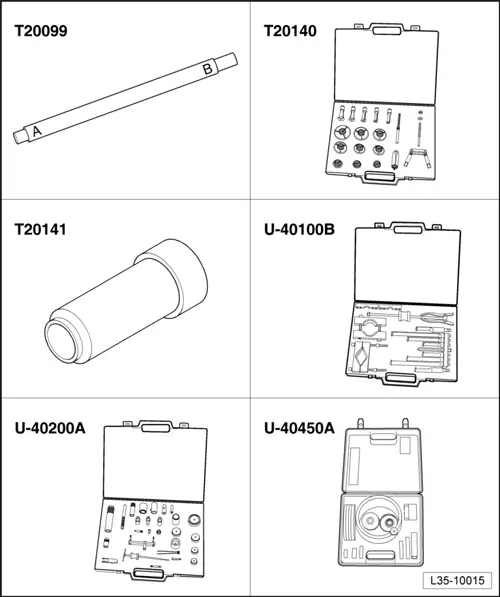

| Special tools and workshop equipment required |

| t | Tappet -T20099 -, see equivalent → Anchor |

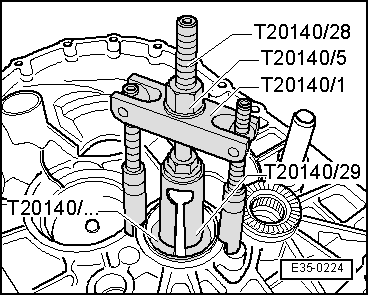

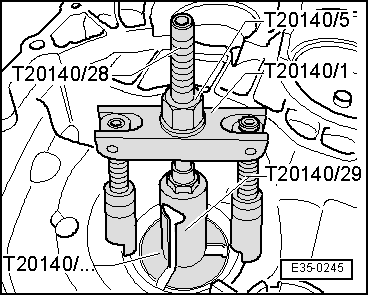

| t | Extractor kit -T20140 -, see equivalent → Anchor |

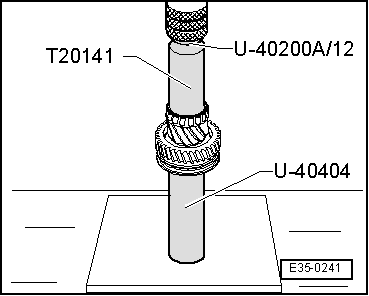

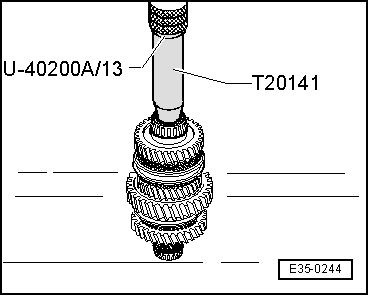

| t | Hose clamp -T20141 -, see equivalent → Anchor |

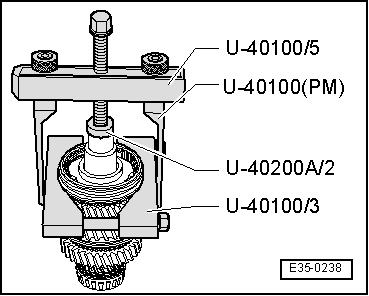

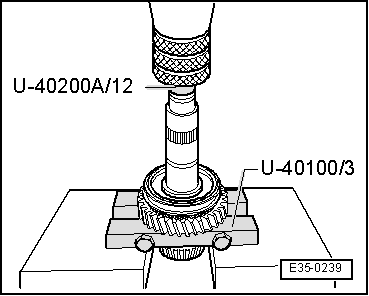

| t | Extractor kit -U 40100B -, see equivalent → Anchor |

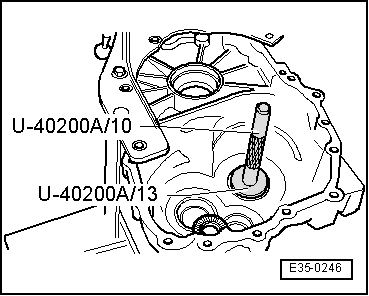

| t | Kit (case) -U-40200A -, see equivalent → Anchor |

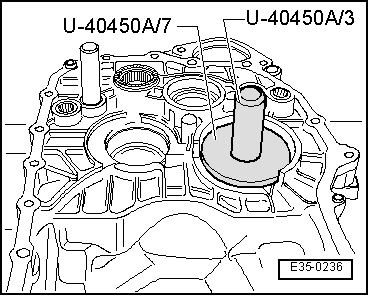

| t | Kit (case) -U-40450A -, see equivalent → Anchor |

| t | Base -A-81124 -, see equivalent → Anchor |

| t | Hose clamp -T20100 -, see equivalent → Anchor |

| t | Tappet -U-40404 -, see equivalent → Anchor |

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

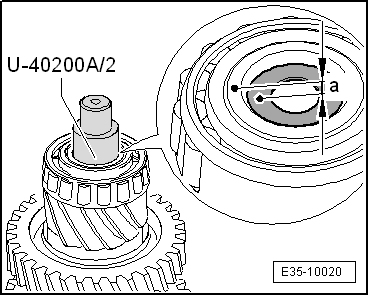

| Thickness (mm) | |||

| 1,79 | 1,83 | 1,86 | 1,89 |

| 1,92 | 1,95 | 1,98 | |

|

|

|

|

|

|

|

|