Leon Mk1

| Secondary shaft for 5th/6th and reverse gear: disassembly and assembly |

| Consult the equivalence table for tools and equipment according to applicability among Seat / VW / Audi / Skoda → Chapter. |

| Special tools and workshop equipment required |

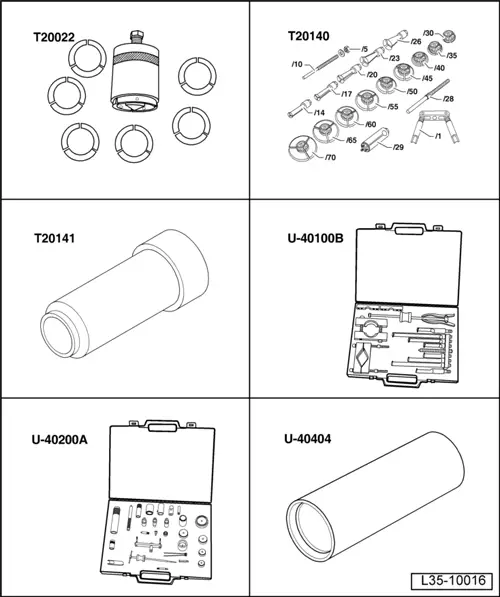

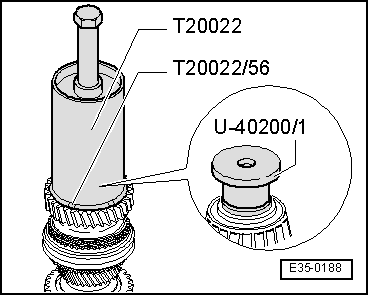

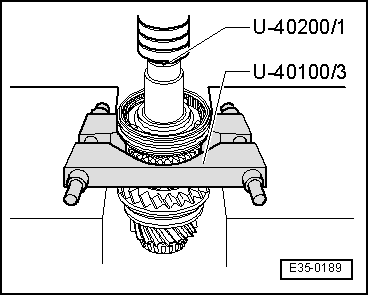

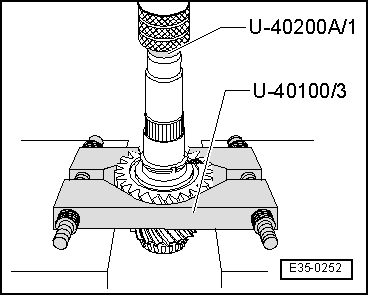

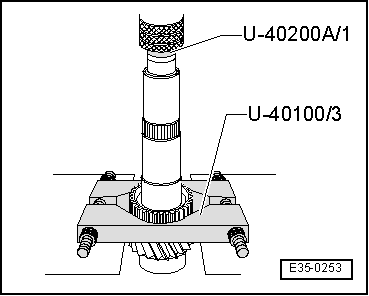

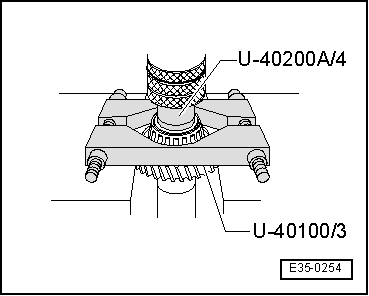

| t | Kit (case) -T20022 -, see equivalent → Anchor |

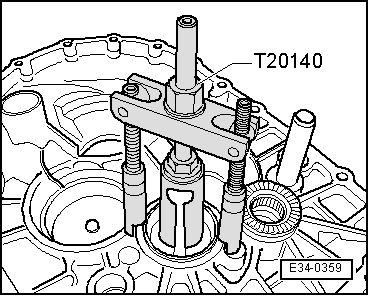

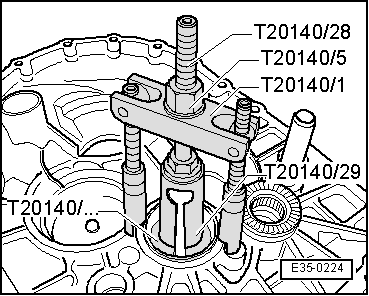

| t | Extractor kit -T20140 -, see equivalent → Anchor |

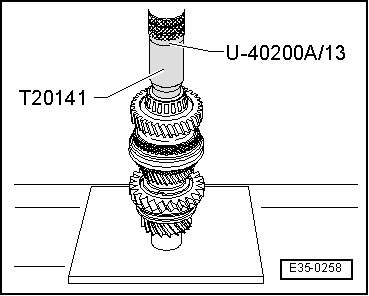

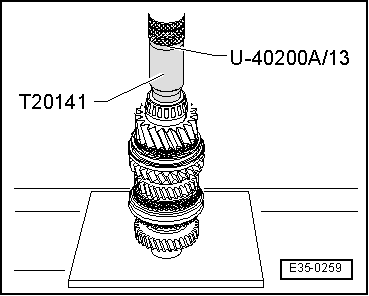

| t | Hose clamp -T20141 -, see equivalent → Anchor |

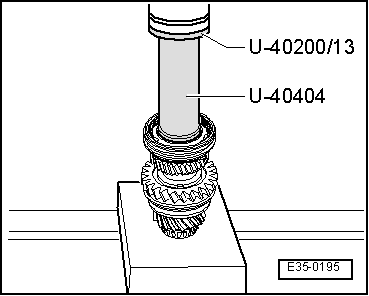

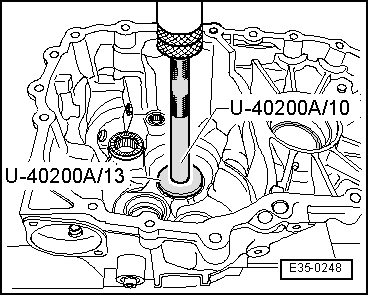

| t | Extractor kit -U 40100B -, see equivalent → Anchor |

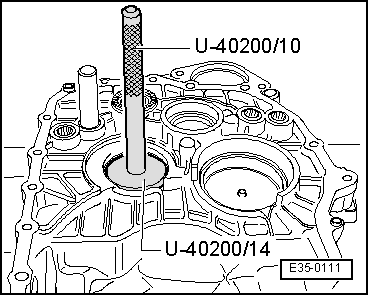

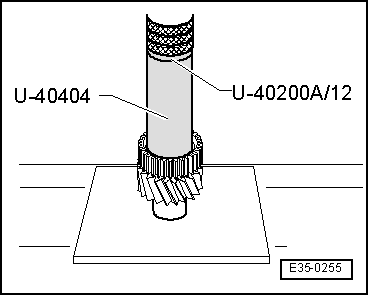

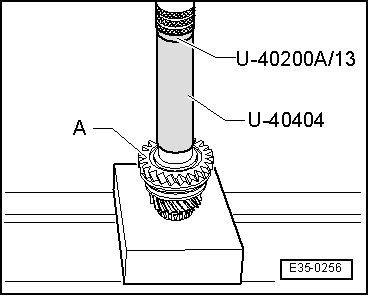

| t | Kit (case) -U 40200A -, see equivalent → Anchor |

| t | Tappet -U-40404 -, see equivalent → Anchor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

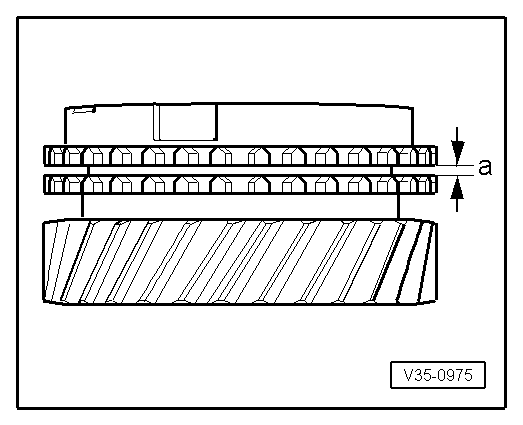

| Installation dimension | Wear limit |

| 1.0 ... 1.7 mm | 0.5 mm |

|

|

|

|

|

|

|

|

|

|

| Thickness (mm) | ||

| 1,79 | 1,89 | 1,98 |

| 1,83 | 1,92 | |

| 1,86 | 1,95 | |

|

|

|

|

|

|

Note

Note