| –

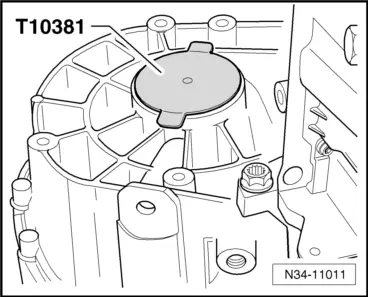

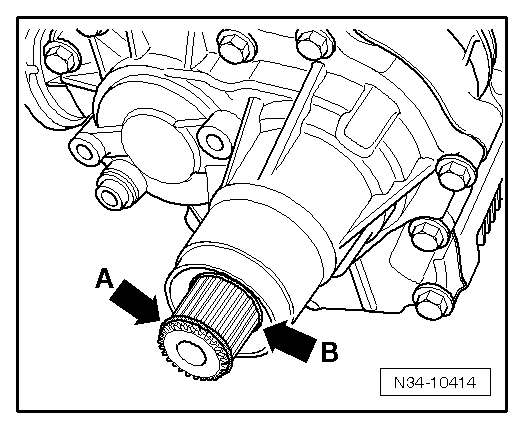

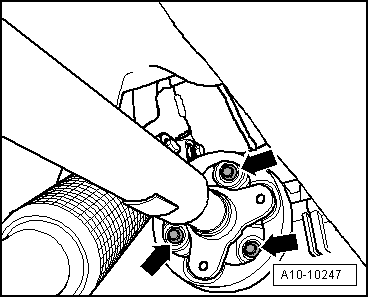

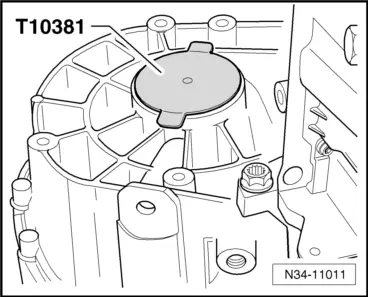

| Remove sealing cap -T10381- from the gearbox. |

| –

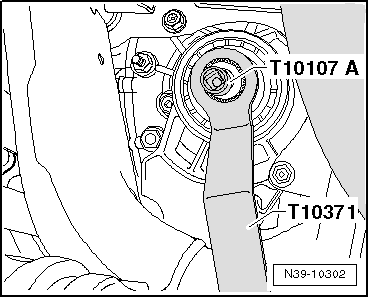

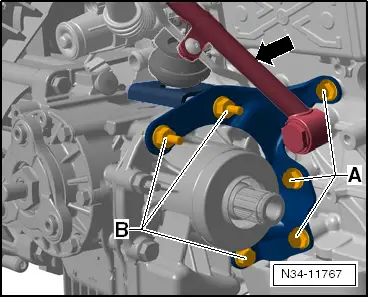

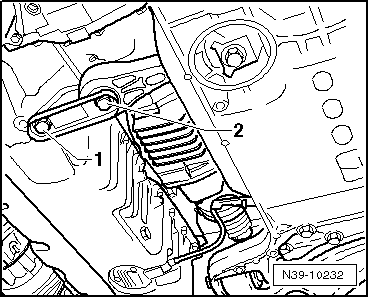

| Grease splines of differential for manual gearbox with grease for clutch plate splines -G 000 100-. |

| –

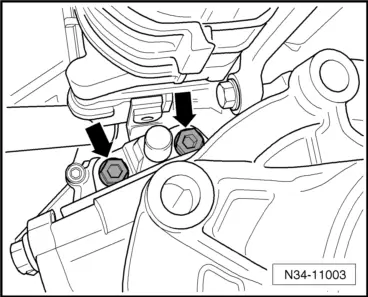

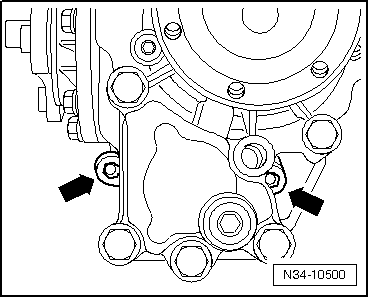

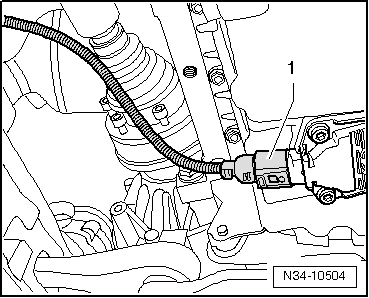

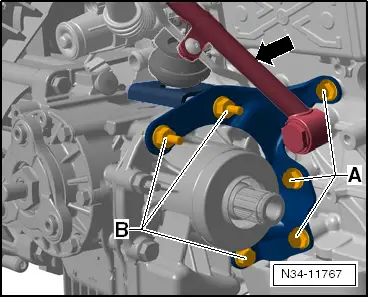

| Push bevel box completely onto gearbox, ensuring that splines of bevel box input shaft and differential are centred when brought together. |

| –

| If splines are correctly positioned and shafts are centred, then bevel box will slide to stop against gearbox. |

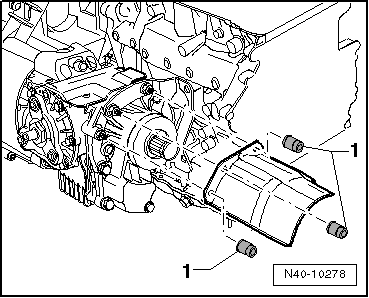

Note | Do not use securing bolts to pull bevel box onto gearbox, or bevel box will cant and bolt holes can break off. |

|

|

|

Note

Note