Leon Mk1

|

|

|

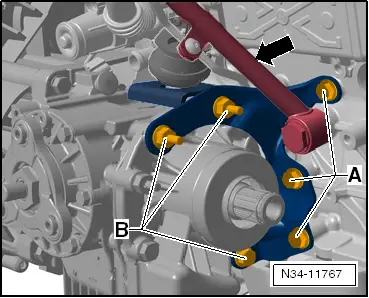

| Special tools and workshop equipment required |

| t | Torque wrench -VAG 1331- |

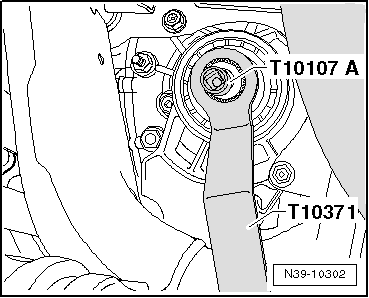

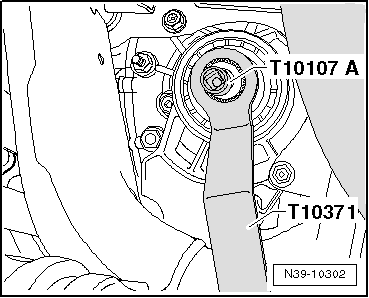

| t | Counter support -T10371- |

| t | Socket -T10107A- |

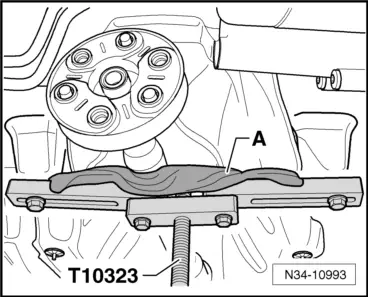

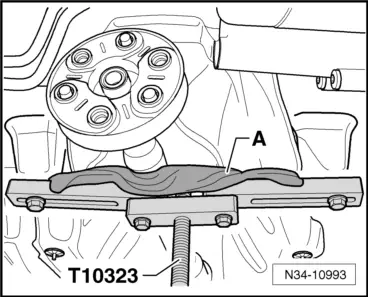

| t | Support bridge -T10323- |

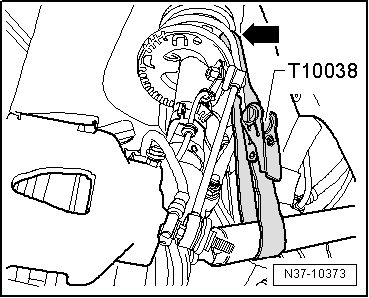

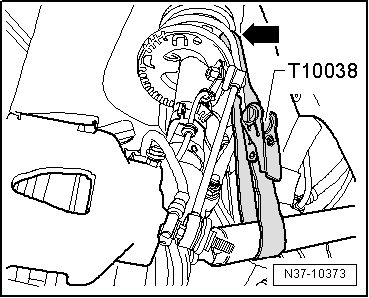

| t | Tensioning strap -T10038- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Special tools and workshop equipment required |

| t | Torque wrench -VAG 1331- |

| t | Counter support -T10371- |

| t | Socket -T10107A- |

| t | Support bridge -T10323- |

| t | Tensioning strap -T10038- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|