Leon Mk1

| Dismantling and assembling differential |

| Special tools and workshop equipment required |

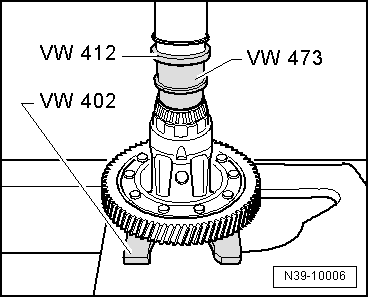

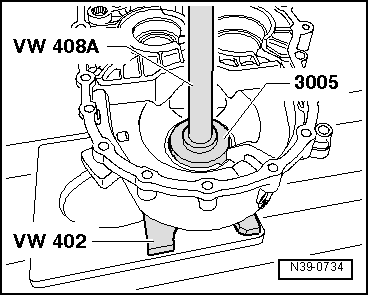

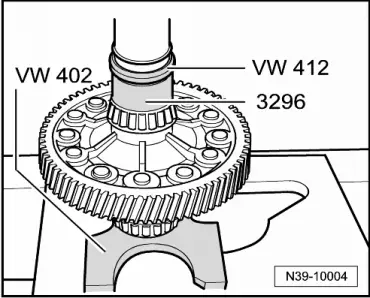

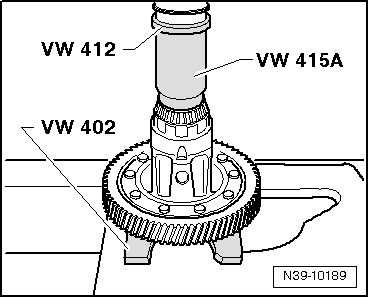

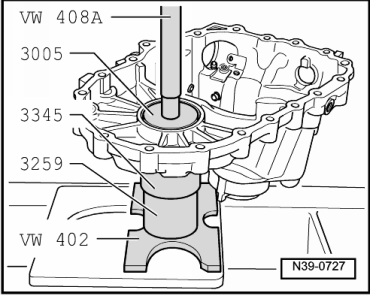

| t | Tightening plate -VW 402- |

| t | Die -VW 408 A- |

| t | Die -VW 412- |

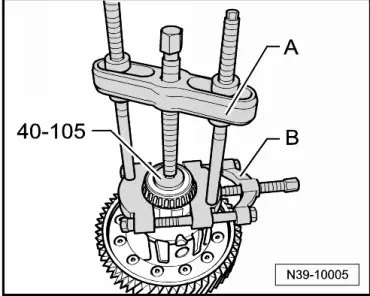

| t | Thrust plate -40-105- |

| t | Thrust plate -3005- |

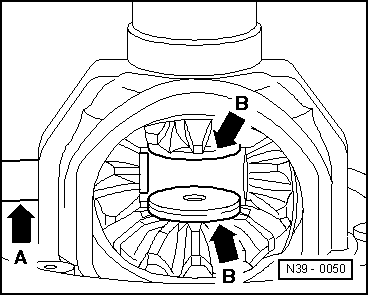

| t | Only gearboxes with right stub shaft |

| t | pressure tool -VW 473- |

|

|

|

| t | Tube -3259- |

| t | Tube -3296- |

| t | Tube -3345- |

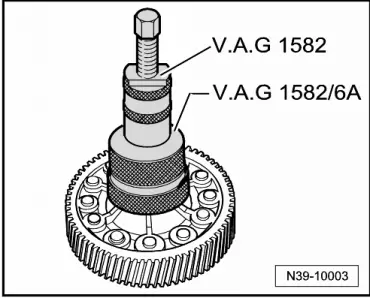

| t | Roller bearing bush extractor -V.A.G 1582- |

| t | Adapter -V.A.G 1582/6A- |

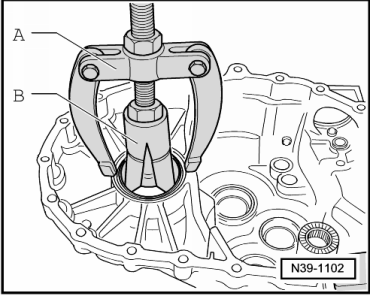

| t | Inside extractor -1 - Kukko 21/7- |

| t | Extractor -2 - Kukko 18/1- |

| t | Splitter -3 - Kukko 17/1- |

| t | Counter-support -4 - Kukko 22/2- |

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|